Steam ironing bottom plate assembly and steam ironing equipment

An ironing board and soleplate technology, applied in the fields of steam ironing soleplate assemblies and steam ironing equipment, can solve problems such as easy scalding of clothes, and achieve the effect of avoiding excessive temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below with reference to the accompanying drawings.

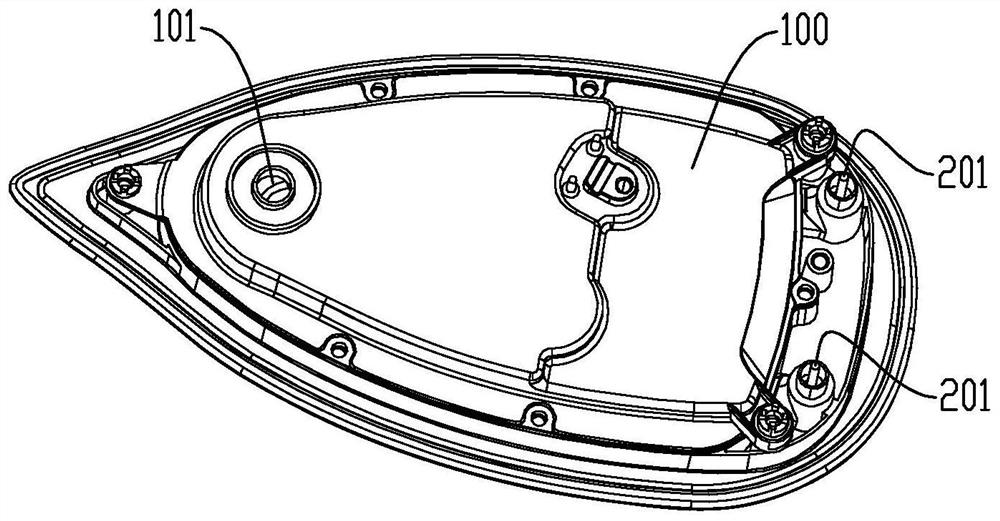

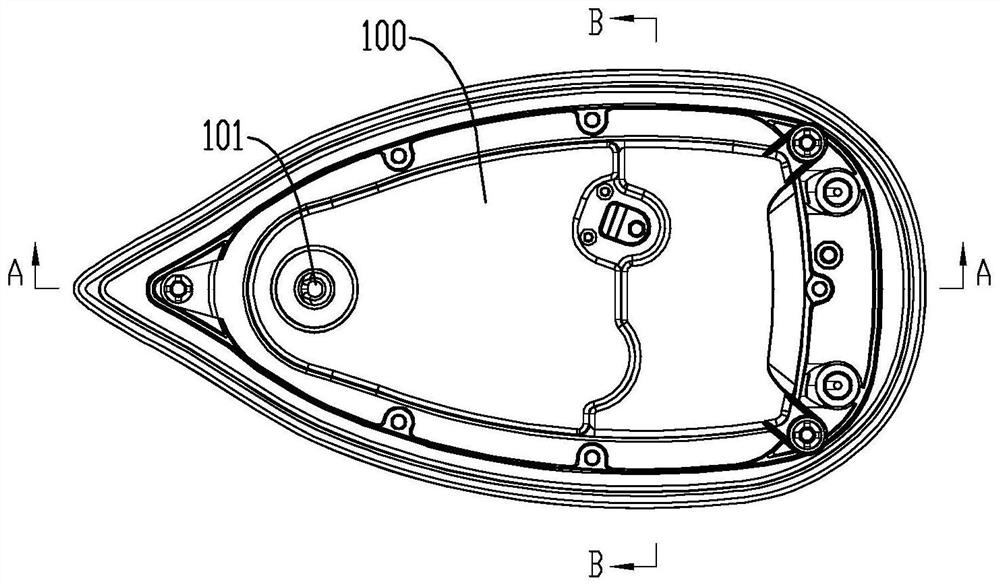

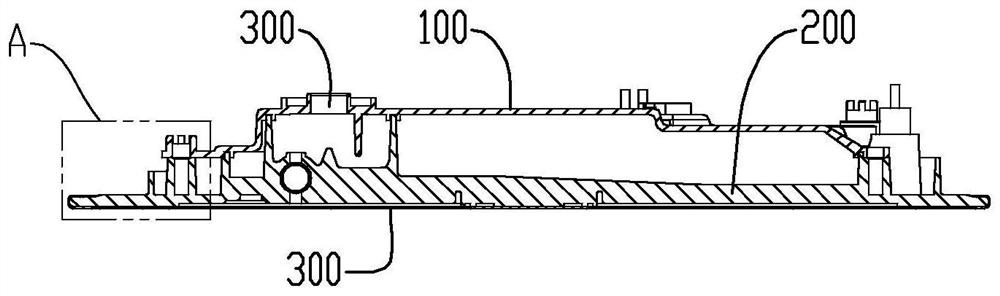

[0037] Such as Figure 1-8 , Figure 10-14 The two structures showing the steam ironing floor assembly applied to the steam iron. They include upper cover 100, bottom plate 200, and ironing plate 300. The upper cover 100 is fitted between the upper side of the bottom plate 200, and the upper cover 100 is formed between the base plate 200. The ironing plate 300 is fitted to the lower side of the bottom plate 200, and the iron plate 300 is formed between the steam cavity 500 between the bottom plate 200. The upper cover 100 has an input hole 101 in a homogenized vapor chamber. The bottom plate 200 built-in heat generating body 201, the bottom plate 200 has a flow hole 202 that delivers steam to the vapor chamber, and the lower surface of the bottom plate corresponding to the portion of the portion of the heat collecting body, the ironing plate is close to the lower surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com