Back passivation matrix dot type laser grooving conductive structure

A rear passivation and laser slotting technology, which is applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problem of laser slotting areas that cannot completely fill a single circular hole-shaped spot, and the large volume of inorganic adhesives and additives mixed , It is not conducive to the collection of photogenerated carriers, etc., to achieve the effect of improving photoelectric conversion efficiency and component reliability, facilitating collection, and improving transmission and collection capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

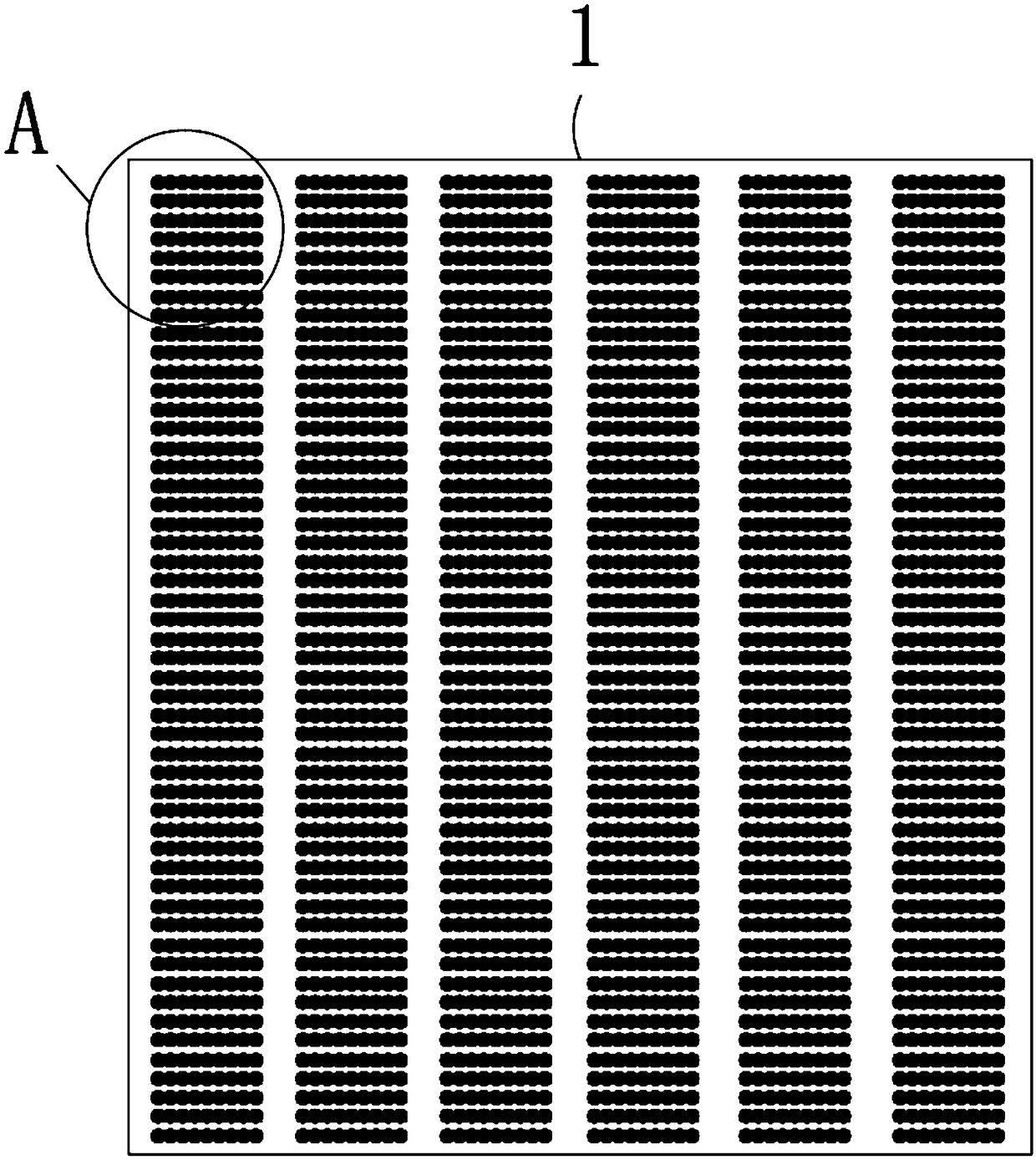

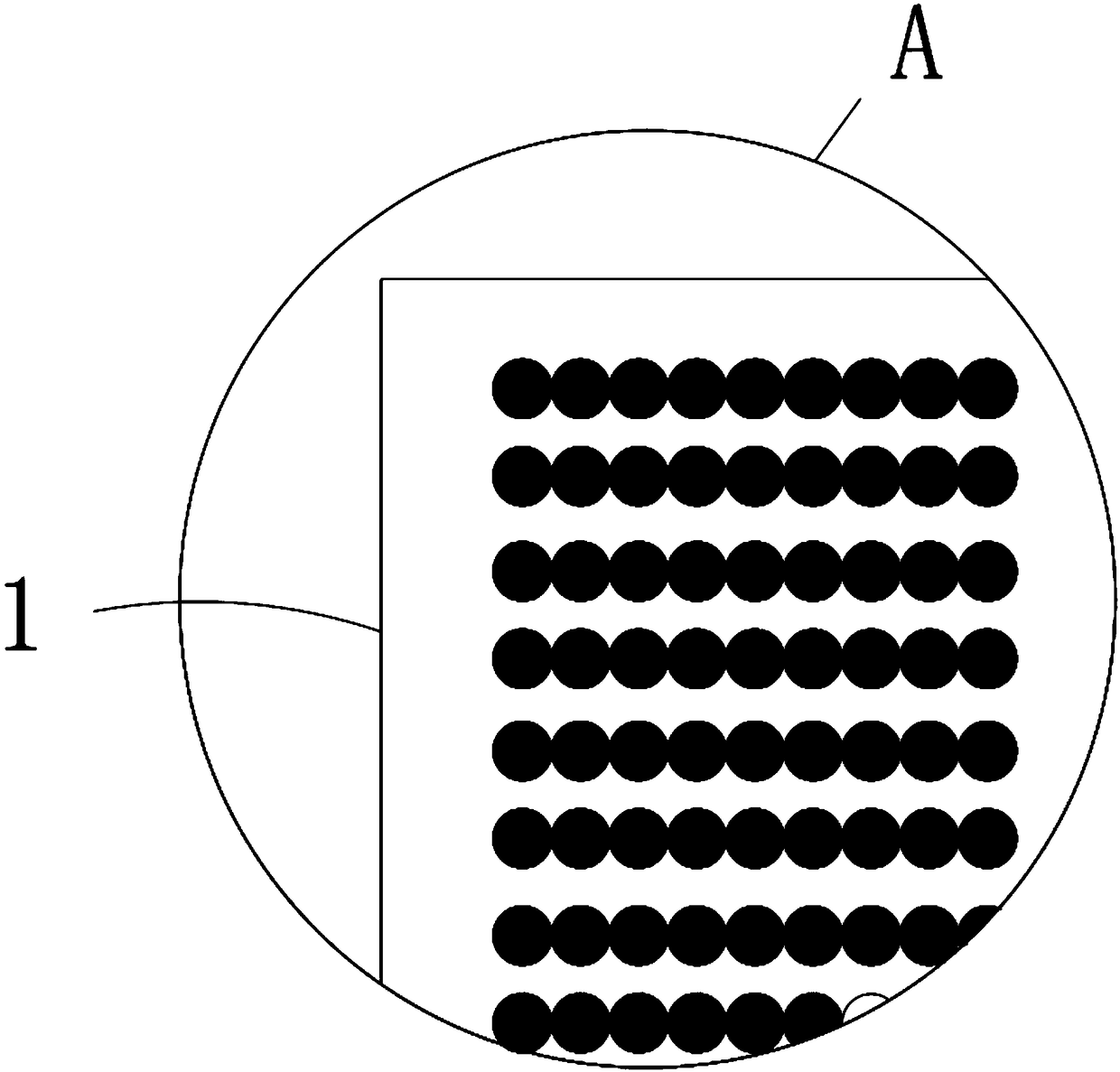

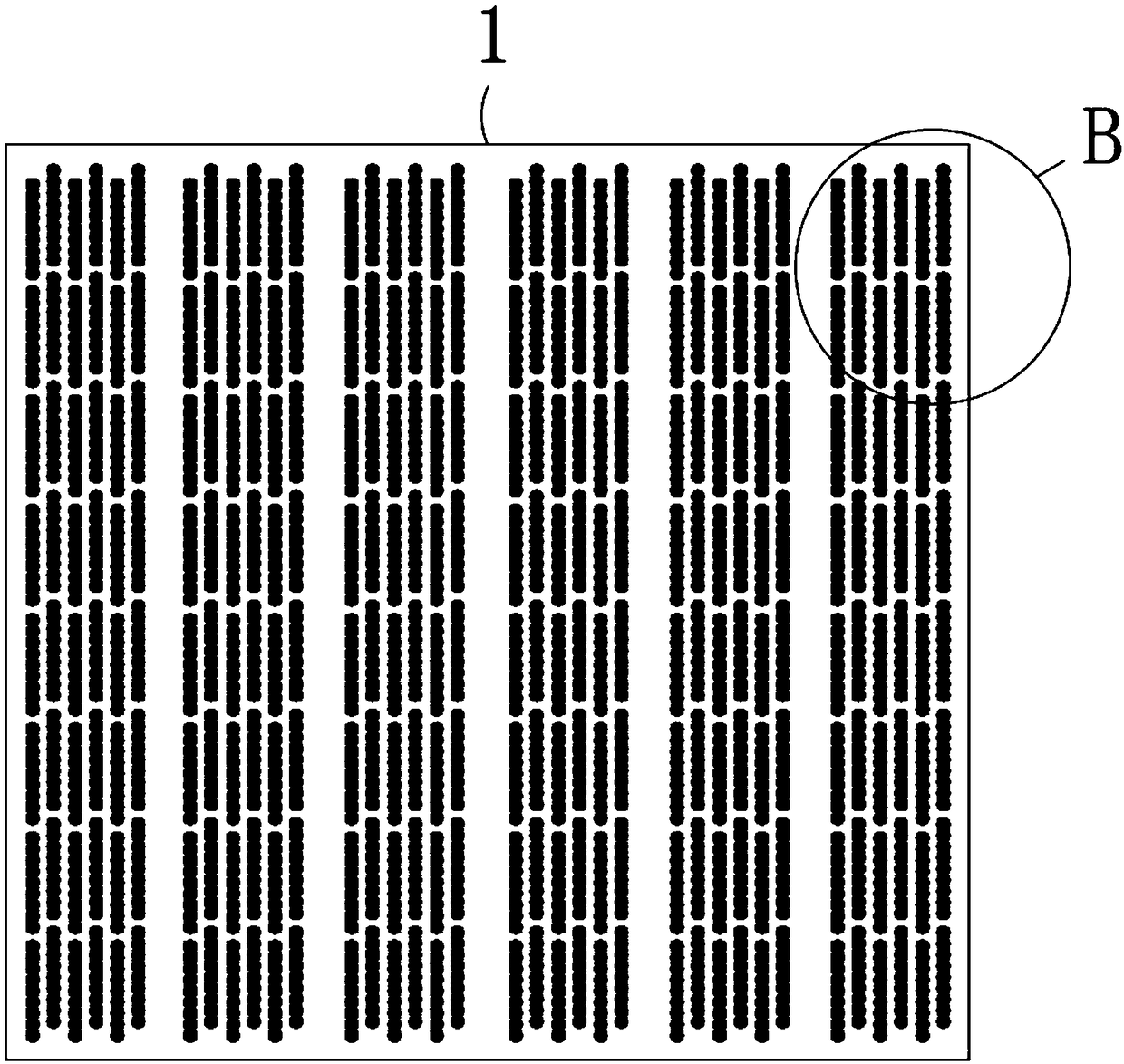

[0040] After front-side texturing, diffusion, cleaning to remove PSG, and backside polishing, removing the back surface of the PN junction polysilicon wafer substrate 1 at the boundary, annealing to form a 2nm SiO2 film, ALD deposition of A2O3 3nm, PECVD deposition of Si3N4 130nm, forming a total thickness of 135nm After stacking the passivation film 2 on the backside, it is turned over, and a silicon nitride anti-reflection passivation protective film layer is deposited on the front surface PN junction region of the silicon wafer substrate 1 by PECVD.

[0041] Five four-segment back electrode busbar regions 3 are arranged on the backside passivation film 2 of the stack, with a length of 18mm and a width of 2.2mm. The backside electrode is to be screen-printed and is 1.5mm away from the edge of the silicon wafer substrate 1. Laser drilling and grooving are not carried out in the inner area, and laser drilling and grooving are used in other areas.

[0042] On the back surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com