Preparation method of D pantoic acid lactone with high conversion rate

A technology with high conversion rate of pantotolactone, which is applied in the field of preparation of high conversion rate D pantotolactone, can solve the problems of affecting conversion rate, low separation efficiency, environmental pollution, etc., and achieve conversion efficiency and conversion degree High, simple extraction, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

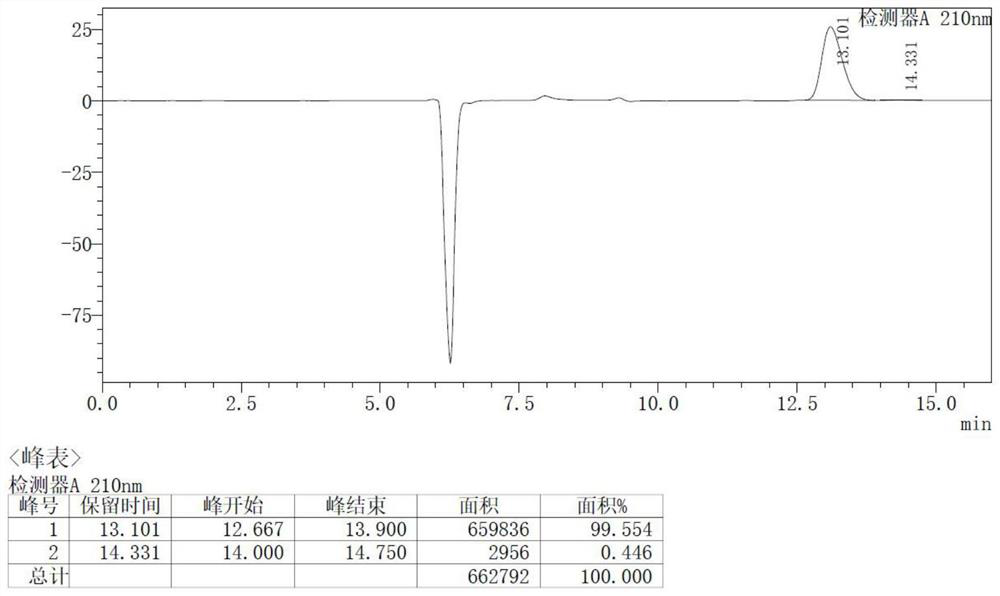

[0050] Example 1 Preparation of D pantolactone

[0051] Weigh 1600gDL pantolactone, 400g ammonium formate, 11.5g ammonium dihydrogen phosphate, add water until the volume of the mixed solution is 10L, stir to dissolve, adjust the pH of the solution to 6.0 with 20-25% ammonia water, heat up to 30°C, add L Pantolactone dehydrogenase, ketopantolactone reductase, and formate dehydrogenase, so that the total enzyme activity in the mixed solution is 8U, and the mixed solution is placed at a constant temperature of 37°C and stirred for 20 hours to obtain a reaction solution . The reaction solution was carried out chromatographic detection, the results are shown in figure 1 . During the reaction, samples were taken every 2 hours to detect and calculate the conversion rate, the results are shown in Figure 6 . The ee value of the reaction product was 99.1%.

Embodiment 2

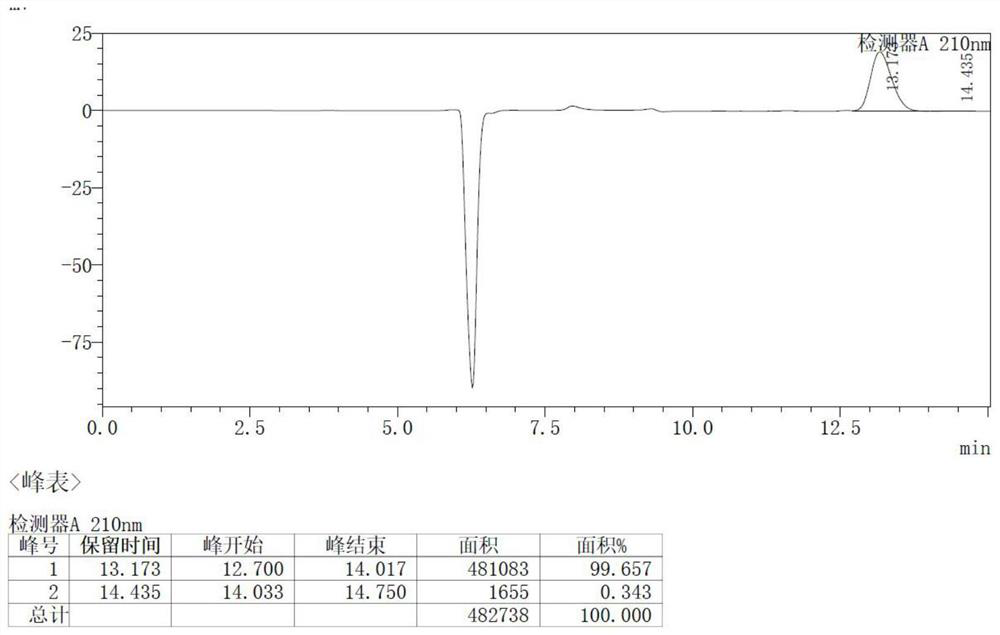

[0052] Example 2 Preparation of D pantolactone

[0053]Weigh 1600gDL pantolactone, 400g ammonium formate, 23g sodium dihydrogen phosphate, add water until the volume of the mixed solution is 10L, stir to dissolve, adjust the pH of the solution to 6.0 with 20-25% ammonia water, heat up to 30°C, add L pan Acetolactone dehydrogenase, ketopantolactone reductase, and formate dehydrogenase, so that the enzyme activity in the mixed solution is 8U, and the mixed solution is placed at a constant temperature of 37°C and stirred for 20 hours to obtain a reaction solution. The reaction solution was carried out chromatographic detection, the results are shown in figure 2 . During the reaction, samples were taken every 2 hours to detect and calculate the conversion rate, the results are shown in Figure 6 . The ee value of the reaction product was 99.3%.

Embodiment 3

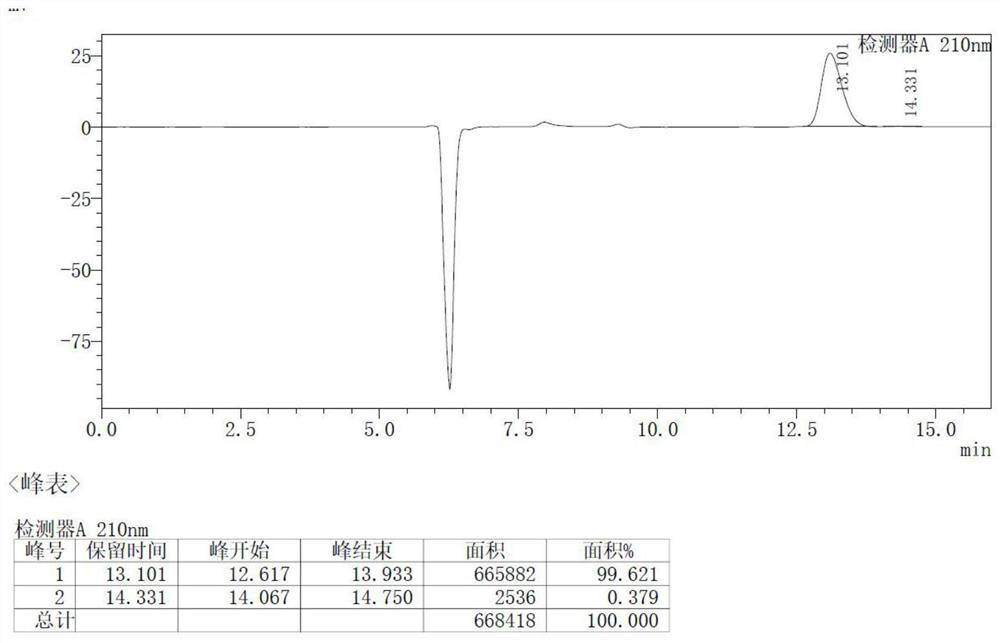

[0054] Example 3 Preparation of D pantolactone

[0055] Weigh 1600gDL pantolactone, 400g ammonium formate, 46g ammonium dihydrogen phosphate, add water until the volume of the mixed solution is 10L, stir to dissolve, adjust the pH of the solution to 6.0 with 20-25% ammonia water, heat up to 30°C, add L pan Acetolactone dehydrogenase, ketopantolactone reductase, and formate dehydrogenase, so that the enzyme activity in the mixed solution is 8U, and the mixed solution is placed at a constant temperature of 37°C and stirred for 20 hours to obtain a reaction solution. The reaction solution was carried out chromatographic detection, the results are shown in image 3 . During the reaction, samples were taken every 2 hours to detect and calculate the conversion rate, the results are shown in Figure 6 . The ee value of the reaction product was 99.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com