3D printing alkali-activated geopolymer composite material doped with hibiscus cannabinus bast fiber crop straw, and preparation method thereof

A bast fiber, 3D printing technology, applied in the field of 3D printing alkali-excited geopolymer composite materials and its preparation, can solve the problems of poor extrusion fluidity, low early strength, easy cracking, etc., and achieve excellent crack resistance, improved The effect of poor shape retention and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

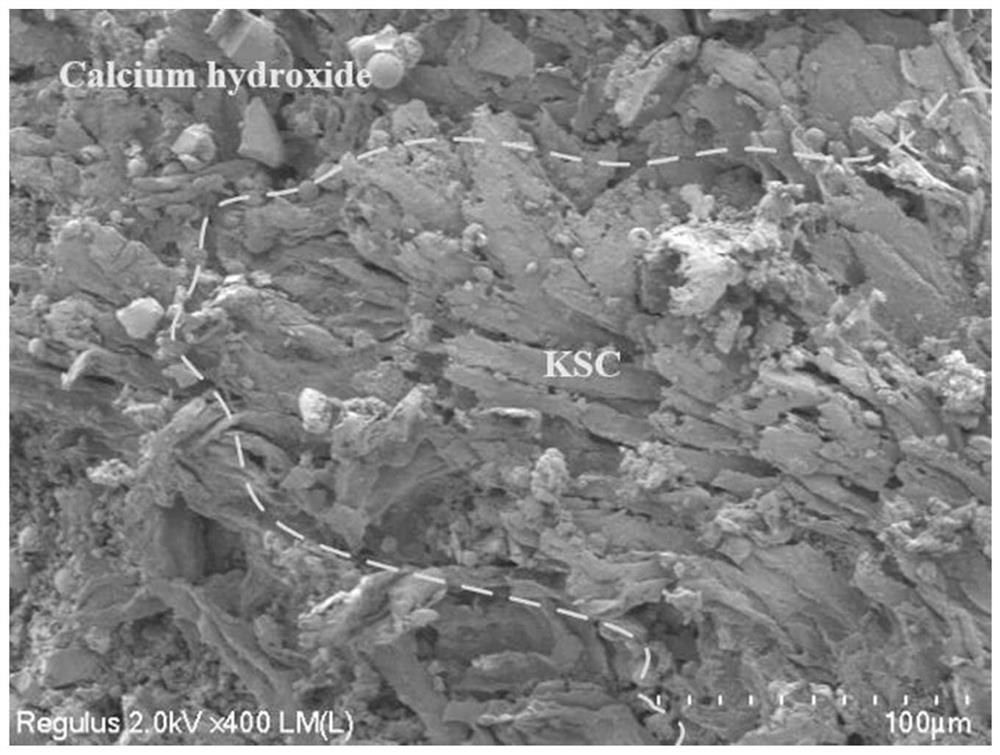

[0032] This example provides a 3D printing alkali-activated geopolymer composite material mixed with kenaf bast fiber crop straw. The raw materials are in parts by weight, 200 parts of slag, 10 parts of lignin, and 800 parts of fly ash. 15 parts of kenaf straw core (screening mesh number is 10-20 mesh), 2 parts of kenaf bast fiber (cutting length is 15 mm), 23 parts of NaOH, 177 parts of water glass, and 180 parts of water.

[0033] Preparation method: Mix and stir the proportioned amount of sodium hydroxide and water glass until completely dissolved to obtain the alkali activator and put it in cooling for later use; mix the proportioned amount of fly ash, slag, kenaf straw core, kenaf bast fiber and wood Mix the mixture evenly, inject alkali activator and water into it, stir at low speed for 1 minute, and then stir at high speed for 5 minutes to obtain a 3D printed alkali-activated geopolymer composite material mixed with kenaf bast fiber crop straw.

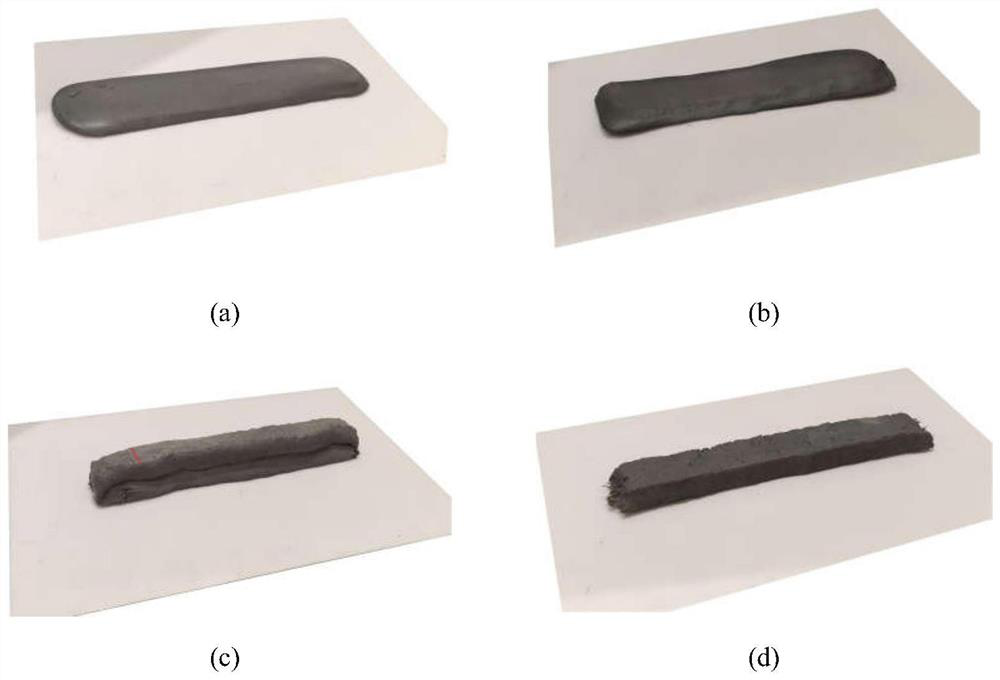

[0034] Finally, after t...

Embodiment 2

[0041] This example provides a 3D printing alkali-activated geopolymer composite material mixed with kenaf bast fiber crop straw. The raw materials are in parts by weight, 400 parts of slag, 10 parts of lignin, and 600 parts of fly ash. 30 parts of kenaf straw core (screening mesh number is 10-20 mesh), 10 parts of kenaf bast fiber (cutting length is 15 mm), 25 parts of NaOH, 200 parts of water glass, and 165 parts of water.

[0042] Preparation method: Mix and stir the proportioned amount of sodium hydroxide and water glass until completely dissolved to obtain the alkali activator and put it in cooling for later use; mix the proportioned amount of fly ash, slag, kenaf straw core, kenaf bast fiber and wood Mix the mixture evenly, inject alkali activator and water into it, stir at low speed for 1 minute, and then stir at high speed for 5 minutes to obtain a 3D printed alkali-activated geopolymer composite material mixed with kenaf bast fiber crop straw.

[0043] The performance...

Embodiment 3

[0046] This example provides a 3D printing alkali-activated geopolymer composite material mixed with kenaf bast fiber crop straw. The raw materials are in parts by weight, 300 parts of slag, 10 parts of lignin, and 700 parts of fly ash. 10 parts of kenaf straw core (screening mesh number is 10-20 mesh), 1 part of kenaf bast fiber (cutting length is 15 mm), 30 parts of NaOH, 170 parts of water glass, and 170 parts of water.

[0047] Preparation method: Mix and stir the proportioned amount of sodium hydroxide and water glass until completely dissolved to obtain the alkali activator and put it in cooling for later use; mix the proportioned amount of fly ash, slag, kenaf straw core, kenaf bast fiber and wood Mix the mixture evenly, inject alkali activator and water into it, stir at low speed for 1 minute, and then stir at high speed for 5 minutes to obtain a 3D printed alkali-activated geopolymer composite material mixed with kenaf bast fiber crop straw.

[0048] The performance t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Clotting time | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com