Grinding aid and cement clinker grinding method using the grinding aid

A grinding method and technology of grinding aids, which are applied in the field of grinding aids, can solve problems such as single ingredients of grinding aids, high grinding energy consumption, and inability to adapt to various complex working conditions of grinding, so as to achieve the effect of improving grinding quality , Improve the effect of grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

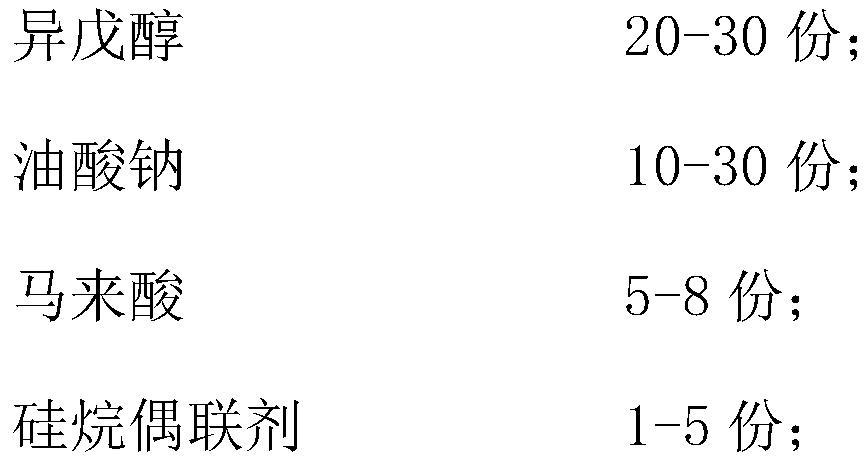

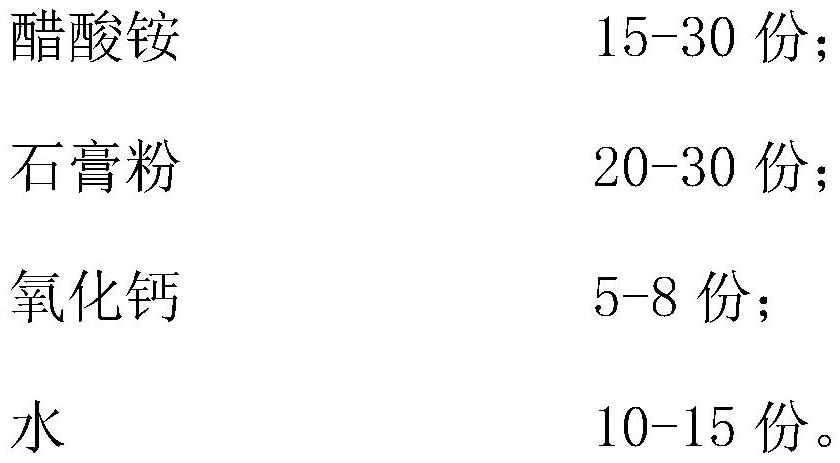

Method used

Image

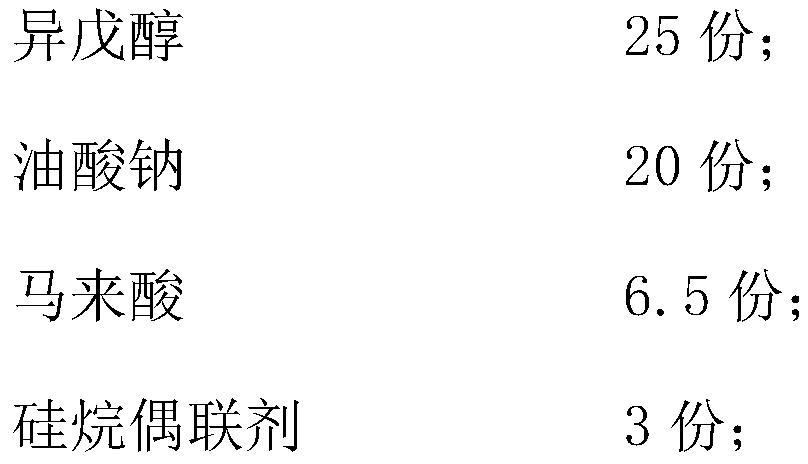

Examples

preparation example 1

[0047] Modified alcohol amine mother liquor preparation method is as follows:

[0048] Step 1: According to the molar ratio of sodium chloroacetate, deionized water, sodium hydroxide and diethanolamine being 1:5:1:1, the raw materials were weighed for later use, and sodium chloroacetate was completely dissolved in deionized water at 50°C to obtain Base liquid; Sodium hydroxide is mixed with the sodium hydroxide aqueous solution that mass concentration is 32%;

[0049]Step 2: adding dropwise an aqueous sodium hydroxide solution with a mass concentration of 32% to the prepared matrix liquid to maintain the pH value of the solution system at 11;

[0050] Step 3: Add diethanolamine dropwise to the solution system obtained in Step 2 at a temperature of 60° C., and stir at this temperature for 1 hour to obtain the modified alcohol amine mother liquor.

preparation example 2

[0052] The difference from Preparation Example 1 is: in step 1, sodium chloroacetate was dissolved in deionized water at 65° C., in step 2, the pH value of the solution system was maintained at 11.5, and in step 3, it was stirred at constant temperature for 1.5 h.

preparation example 3

[0054] The difference from Preparation Example 1 is: in step 1, sodium chloroacetate was dissolved in deionized water at 80° C., in step 2, the pH value of the solution system was maintained at 12, and in step 3, it was stirred at constant temperature for 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com