Method for synchronously lifting and overturning workpiece on two sides

A technology of synchronous lifting and workpiece, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of inaccurate flipping and positioning, low work efficiency, etc., to reduce flipping time, less operation process, and save labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

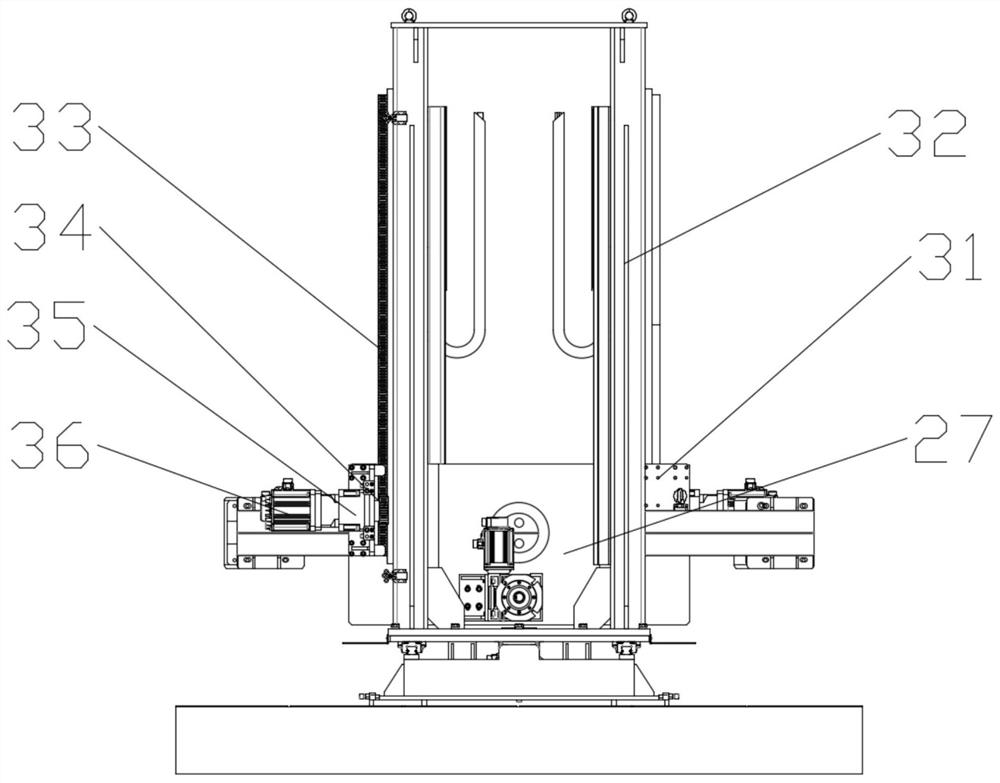

[0030] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0031] like Figure 1-4 As shown, the method of double-sided synchronous lifting and flipping of the workpiece includes the following steps:

[0032] Step 1: Start the two horizontal movement components 4, the movement of the horizontal movement components 4 makes the lifting component 3 and the rotation mechanism 2 move toward the workpiece, and the rotation mechanism 2 moves toward the workpiece to insert the inserts 12 on the two workpiece clamping components 1 In the long hole of the corner piece of the workpiece, the workpiece is fixed between the two workpiece clamping assemblies 1;

[0033] Step 2: Start the two lifting components 3 synchronously. The lifting component 3 makes the rotating mechanism 2 rise, and the rotating mechanism 2 rises to make the workpiece clamping component 1 rise with the workpiece, so that the workpiece ris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com