A fuel cell recovery method

A fuel cell and recovery method technology, which is applied in the direction of fuel cells, circuits, electrical components, etc., can solve the problems of reducing the service life of fuel cells, fuel cell performance attenuation, and proton exchange membrane attenuation, so as to improve user experience and restore output performance , the effect of restoring performance output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

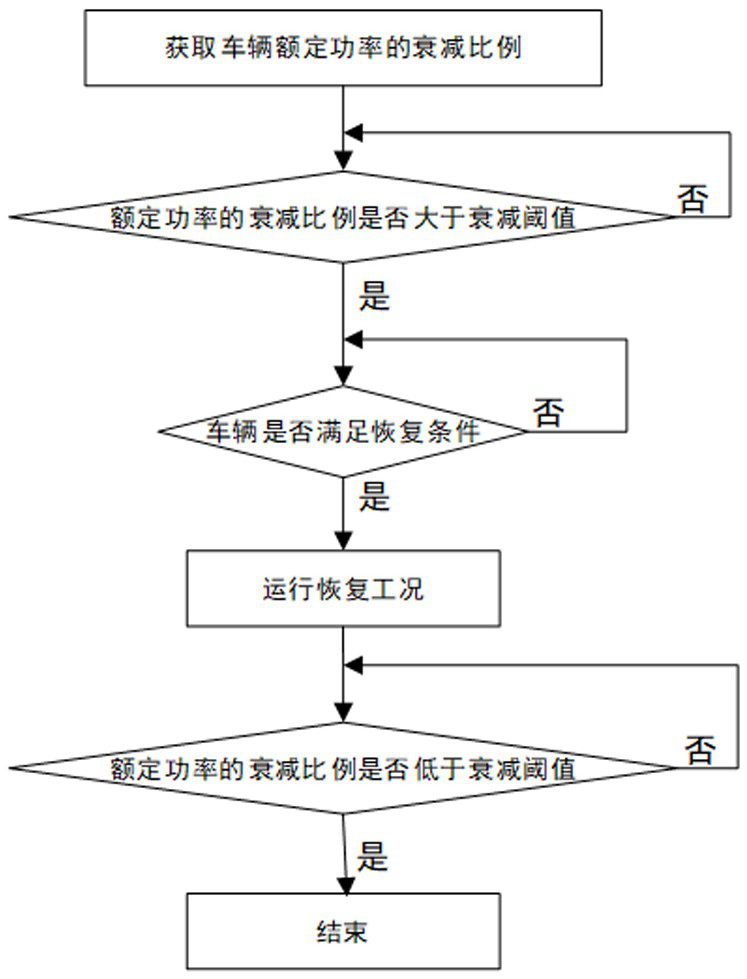

[0028] refer to figure 1 , a fuel cell recovery method of the present invention, comprising the following steps:

[0029] S1. Detect the attenuation ratio of the output rated power of the fuel cell system: calculate the difference between the calibrated output power and the actual output power to obtain the power drop value, and then calculate the ratio of the power drop value to the calibrated output power to obtain the attenuation of the rated power Proportion; determine whether the attenuation ratio of the rated power is greater than the attenuation threshold; if so, enter the next step; if not, the fuel cell does not need to be restored; the attenuation threshold is 2% of the initial power;

[0030] S2. Whether the system self-test meets the recovery conditions; if so, go to the next step; if not, it cannot be recovered;

[0031] S3. Under the rated current gear, gradually reduce the cathode inlet pressure. The step size of the pressure reduction is 2KPa, and the interval...

Embodiment 2

[0034] S1. Detect the attenuation ratio of the output rated power of the fuel cell system; calculate the difference between the calibrated output power and the actual output power to obtain the power drop value, and then calculate the ratio of the power drop value to the calibrated output power to obtain the attenuation of the rated power Proportion; determine whether the attenuation ratio of the rated power is greater than the attenuation threshold; if so, enter the next step; if not, the fuel cell does not need to be restored; the attenuation threshold is 10% of the initial power;

[0035] S2. Whether the system self-test meets the recovery conditions; if so, go to the next step; if not, it cannot be recovered;

[0036] S3. Under the rated current gear, gradually reduce the cathode inlet pressure, the step size of step-down is 6KPa, and the interval is 15 seconds. The anode inlet pressure is kept higher than the cathode pressure by 15KPa, and the average single-chip voltage V...

Embodiment 3

[0039]S1. Detect the attenuation ratio of the output rated power of the fuel cell system: Calculate the difference between the calibrated output power and the actual output power to obtain the power drop value, and then calculate the ratio of the power drop value to the calibrated output power to obtain the attenuation of the rated power Proportion; determine whether the attenuation ratio of the rated power is greater than the attenuation threshold; if so, enter the next step; if not, the fuel cell does not need to be restored; the attenuation threshold is 20% of the initial power;

[0040] S2. Whether the system self-test meets the recovery conditions; if so, go to the next step; if not, it cannot be recovered;

[0041] S3. Under the rated current gear, gradually reduce the cathode inlet pressure. The step size of step-down is 10KPa, and the interval is 30 seconds. The anode inlet pressure is kept higher than the cathode pressure by 30Pa. If it is lower than the minimum rated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com