Manufacturing method of LED epitaxial wafer

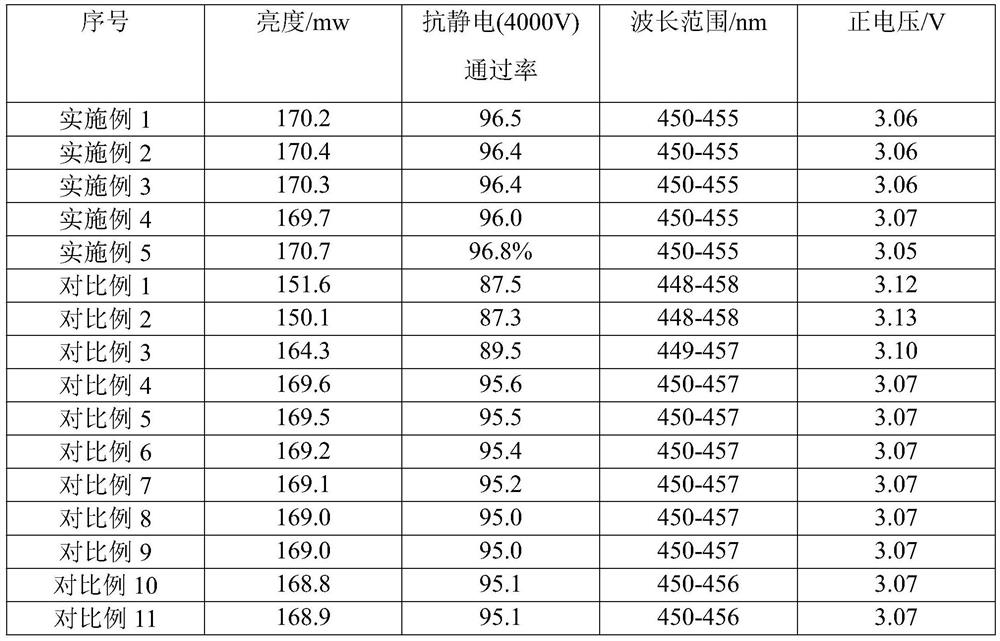

A technology of LED epitaxial wafer and manufacturing method, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of low brightness of LED epitaxial wafer, hinder LED performance, reduce energy saving effect, etc., so as to improve antistatic ability and increase wavelength. Concentration, the effect of improving wavelength uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

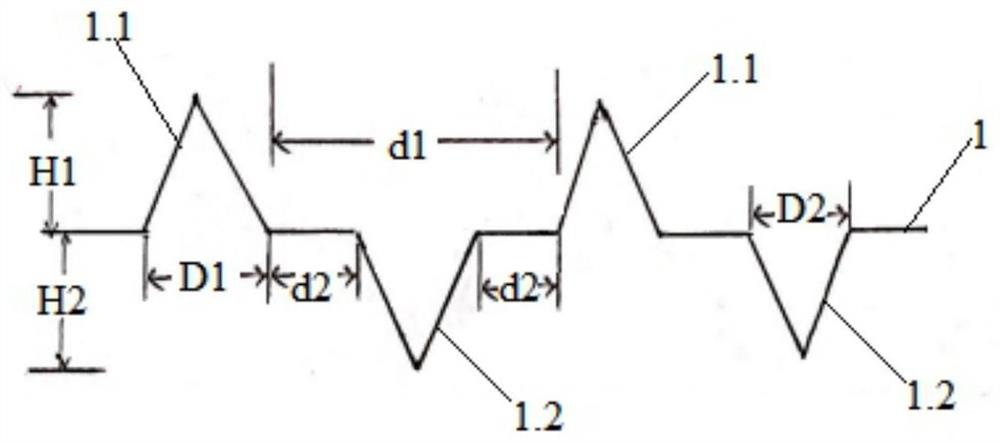

[0033] see figure 1 , a method for manufacturing an LED epitaxial wafer, comprising the following steps,

[0034] Step 3, making a plurality of raised cones 1.1 at intervals on the AlN layer 1;

[0035] Step 4: Fabricate a plurality of concave and inverted conical cavities 1.2 at intervals on the AlN layer 1, the conical cavities 1.2 and the cones 1.1 are arranged alternately and are not connected in pairs, that is, between any two adjacent conical cavities 1.2 Set a cone 1.1, and set a cone cavity 1.2 between any two adjacent cones 1.1;

[0036] Step 5, periodically growing a plurality of multi-quantum well light-emitting layers on the AlN layer 1, each of the multi-quantum well light-emitting layers includes sequentially grown InGaN well layers and GaN barrier layers, wherein the multi-quantum well light-emitting layers grown in the first period The well light-emitting layer is used to fill up the conical cavity 1.2 in the step 4. From the second cycle, the multi-quantum w...

Embodiment 2

[0050] Different from Example 1, in step 3, D1 is 1000nm, height H1 is 850nm, the shortest distance d1 between the bottom surfaces of adjacent cones 1.1 is 2100nm, and in step 4, D2 is 800nm, and height H2 is 850nm. The shortest distance d2 between the top surface of the conical cavity 1.2 and the bottom surface of the adjacent cone 1.1 is 500nm, and the thickness of the AlN layer 1 is 1800nm.

Embodiment 3

[0052] Different from Example 1, in step 3, D1 is 1100nm, height H1 is 900nm, and the distance d1 between the bottom surfaces of adjacent cones 1.1 is 2200nm, and in step 4, D2 is 900nm, and height H2 is 900nm. The shortest distance d2 between the top surface of the cavity 1.2 and the bottom surface of the adjacent cone 1.1 is 600nm, and the thickness of the AlN layer 1 is 2000nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com