Flexible coordination control method for external steam supply unit

A coordinated control and flexible technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of unit economy, safety, difficulty in taking into account, steam volume reduction, and increase in assessment, etc., and achieve one-time enhancement. Frequency modulation responsiveness, effect of increased steam volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings.

[0018] A flexible coordination control method of external dilutifier unit, including the following steps:

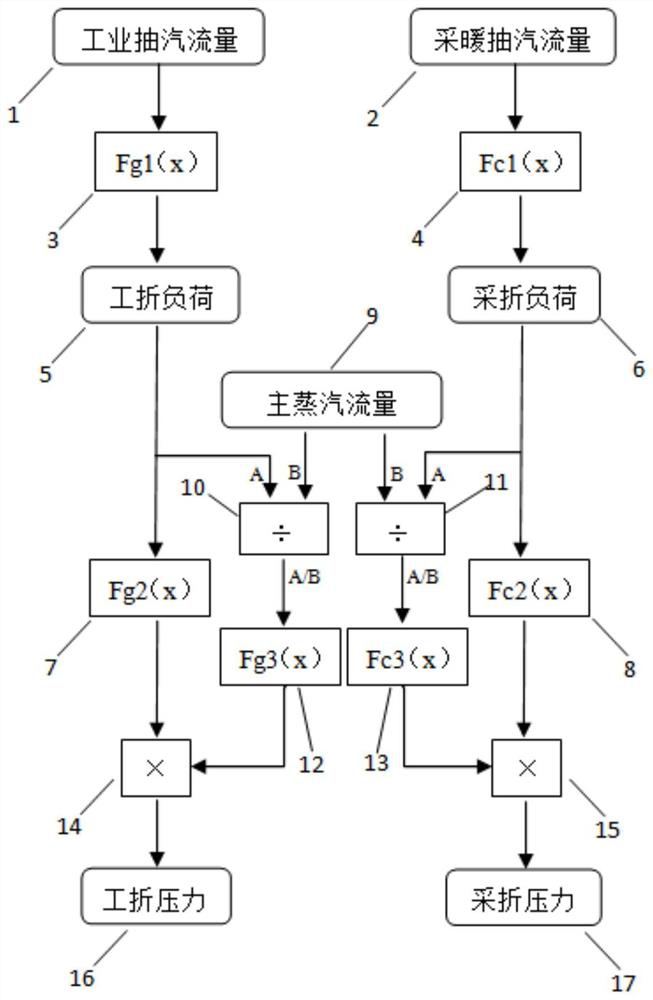

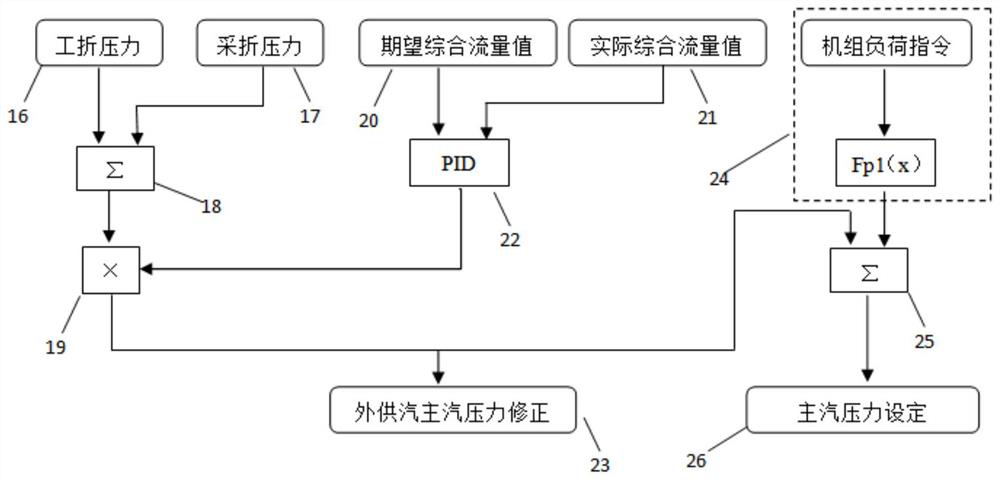

[0019] Step (1), the industrial stroke flow rate is obtained by the a dimension conversion module to obtain a folded load, the heating stroke flow is obtained through the B dimensional conversion module, and the folding load is re-transforms the module and the load is loaded. Dynamic correction with the main vapor flow ratio, get a pressure reduction pressure; the folding load is re-exchanged by the D dimension conversion module and the dynamic correction of the folded load and the main steam flow ratio, the discount pressure is obtained; After the pressure is dynamically corrected by the composite flow PID closed loop controller, superimposing with the conventional host vapor pressure set loop, as the final main vapor pressure set value;

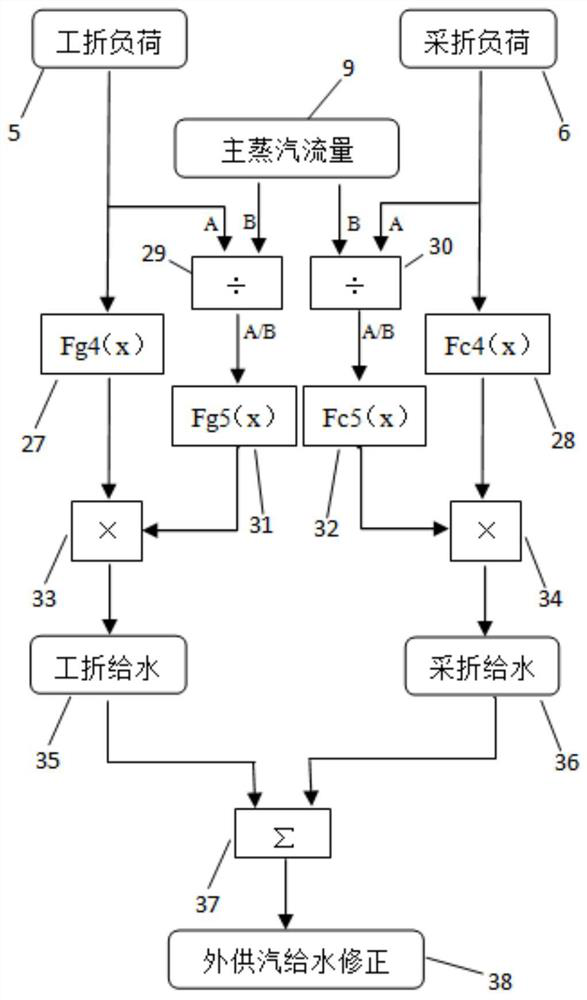

[0020] Step (2), the foldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com