Method and treatment system for reducing nitrogen oxides by using incineration of refuse landfill gas

A technology for landfill gas and treatment system, which is applied in the field of landfill gas combustion and reburning, can solve the problems of narrow effective reaction temperature range, high operating cost of flue gas treatment, and difficulty in popularization and use, so as to reduce the burden of purification treatment and facilitate the Effective provision and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

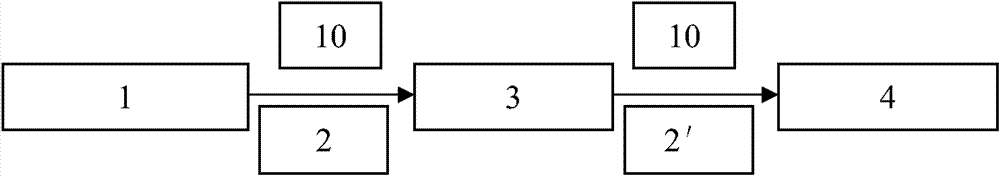

[0018] Now describe the embodiment of the patent of the present invention in detail in conjunction with the accompanying drawings: as figure 1 As shown, a treatment system for reducing nitrogen oxides by using landfill gas incineration, the treatment system is mainly composed of a landfill 1, an air duct 2, a fan 3, another air duct 2′, and an incinerator 4 connected in sequence . combine figure 1 , 2 As shown, the working method of the system includes the following steps: (1), the landfill gas 10 of the landfill 1 is drawn out by the fan 3 through the air duct 2, and then sent into the garbage incinerator 4 through another air duct 2′ (2), will enter one road landfill gas spout of incinerator 4 and be located at the combustion section 41 of incinerator, landfill gas 10 and incinerator primary air 20 react incineration at the bottom of incinerator, both can improve the rubbish burning in the furnace Calorific value, raising the temperature of the furnace can also play the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com