System and method for improving heat exchange effects of graphite blocks in HCl synthetic furnace with byproduct steam

A technology of heat exchange effect and by-product steam, applied in the direction of chlorine/hydrogen chloride, etc., can solve problems such as loss of chlor-alkali manufacturers, graphite block bursting, serious problems, etc., and achieve the effect of reducing the risk factor of accidents, reducing installation and maintenance costs, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

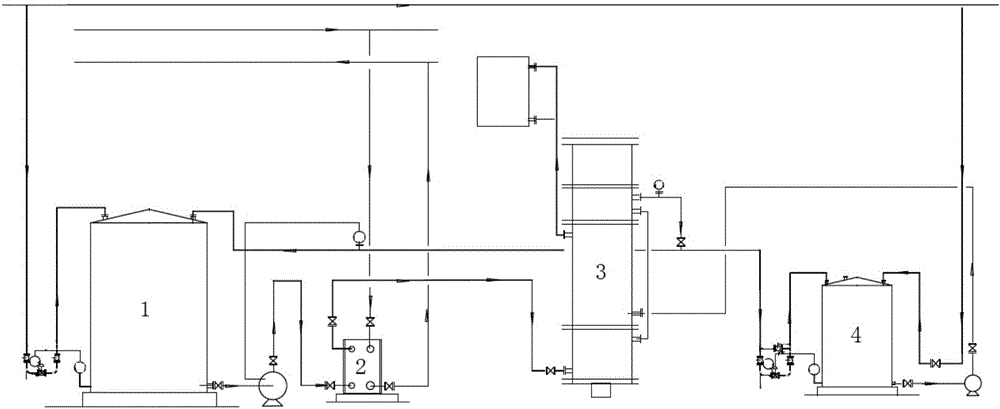

[0027] After the pure water in the first water tank 1 is exchanged by the heat exchanger 2, the temperature is 34°C, and it enters the lower end of the circulating water section of the synthesis furnace 3, and the flow rate of the water is 45m 3 / h, and then return water from the upper outlet of the circulating water section of the synthesis furnace 3 to the first water tank 1; the hot water in the middle of the circulating water section of the synthesis furnace 3 enters the second water tank 4, and the temperature of the hot water is 50°C , the hot water in the second water tank 4 is under the pressurization of the first water pump, the pressure of the first water pump is 0.34Mpa, returns to the synthesis furnace 3, and the hot water flow rate is 23m 3 / h, low-pressure steam is generated, and the pressure of the steam is 0.23-0.26Mpa.

[0028] After heat exchange, the original circulating water returns to the cooling tower to cool down. The heat is wasted. After the transform...

Embodiment 2

[0032] After the pure water in the first water tank 1 is exchanged by the heat exchanger 2, the temperature is 27°C, and it enters the lower end of the circulating water section of the synthesis furnace 3, and the flow rate of the water is 50m 3 / h, and then return water from the upper outlet of the circulating water section of the synthesis furnace 3 to the first water tank 1; the hot water in the middle of the circulating water section of the synthesis furnace 3 enters the second water tank 4, and the temperature of the hot water is 45°C , the hot water in the second water tank 4 is under the pressurization of the first water pump, the pressure of the first water pump is 0.36Mpa, returns to the synthesis furnace 3, and the hot water flow rate is 22m 3 / h, low-pressure steam is generated, and the pressure of the steam is 0.23-0.260Mpa.

[0033] After heat exchange, the original circulating water returns to the cooling tower to cool down. The heat is wasted. After the transfor...

Embodiment 3

[0037] After the pure water in the first water tank 1 is exchanged by the heat exchanger 2, the temperature is 30°C, and enters the lower end of the circulating water section of the synthesis furnace 3, and the water flow rate is 45m 3 / h, and then return water from the upper outlet of the circulating water section of the synthesis furnace 3 to the first water tank 1; the hot water in the middle of the circulating water section of the synthesis furnace 3 enters the second water tank 4, and the temperature of the hot water is 50°C , the hot water in the second water tank 4 is under the pressurization of the first water pump, the pressure of the first water pump is 0.37Mpa, returns to the synthesis furnace 3, and the hot water flow rate is 25m 3 / h, low-pressure steam is produced, and the pressure of the steam is 0.230.260Mpa.

[0038] After heat exchange, the original circulating water returns to the cooling tower to cool down. The heat is wasted. After the transformation, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com