Multifunctional wool composite yarn and preparation method thereof

A composite yarn and multi-functional technology, applied in the direction of yarn, coating, filament/thread forming, etc., can solve the problems of antistatic and strength without advantages, and achieve the effect of light weight, improved thermal performance and increased added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

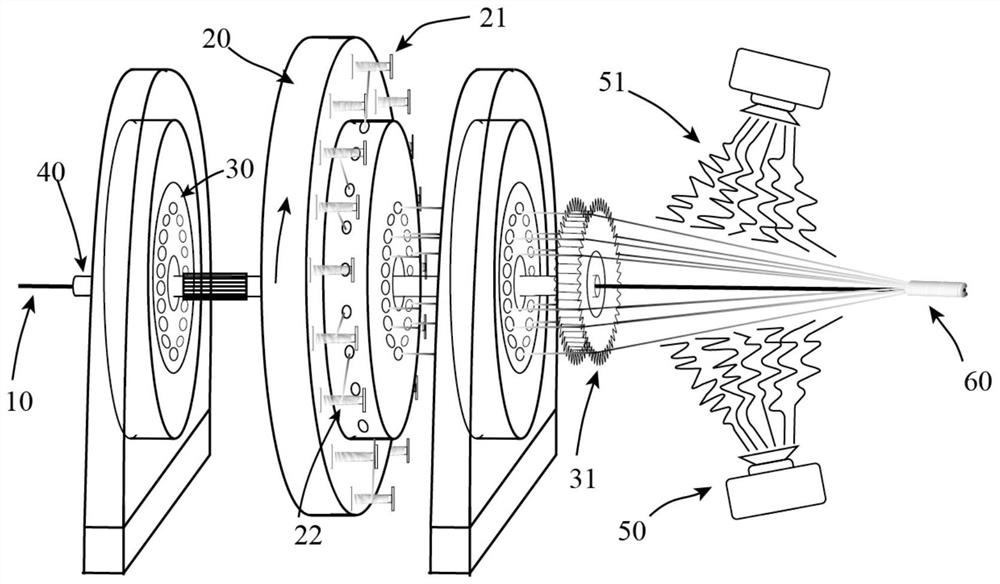

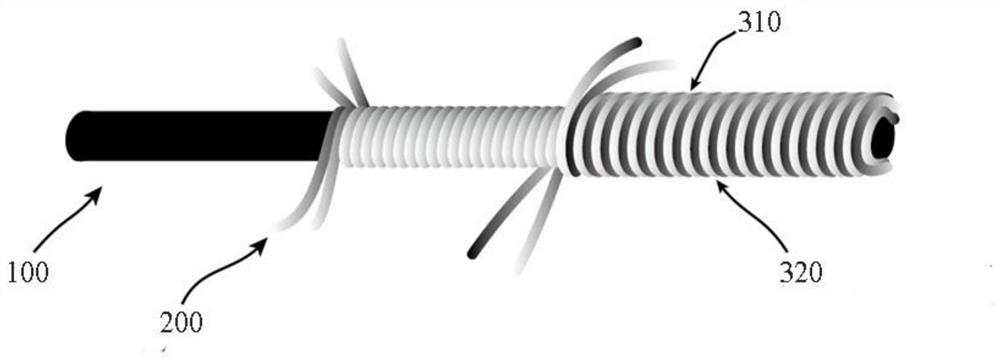

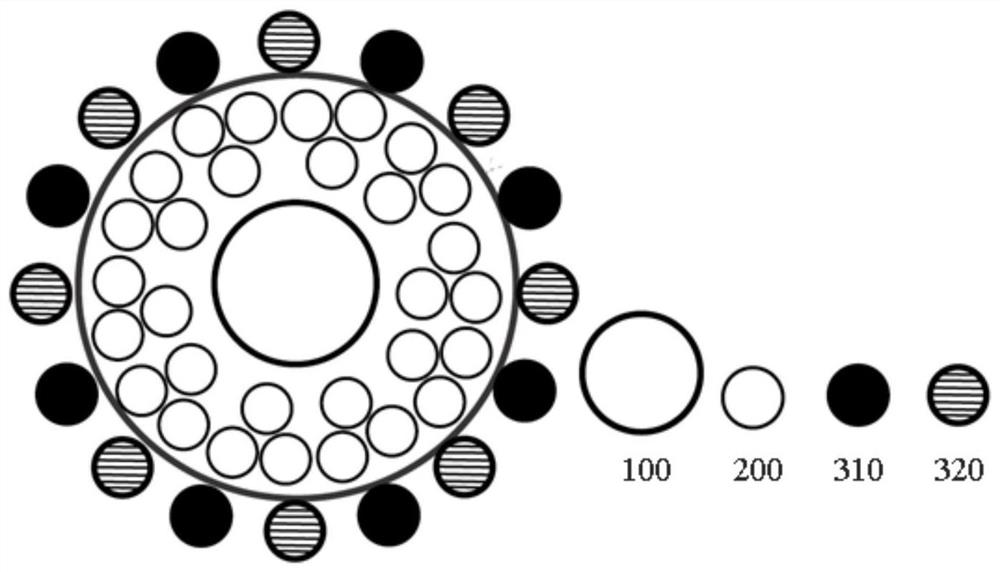

[0040] The present embodiment provides a kind of preparation method of multifunctional wool composite yarn, comprises the following steps:

[0041] (1) Nylon 66 is used as the core yarn, and the core yarn is passed through the center of the yarn covering device.

[0042](2) Assemble 6 groups of wool / chitin mixed fibers on the outer yarn feeding mechanism, and each group consists of three wool / chitin mixed fibers.

[0043] (3) Set the rotating speed of the outer covering yarn feeding mechanism to 90r / min, and cover the wool / chitin mixed fiber clockwise on the core yarn.

[0044] (4) The graphene / polyvinyl alcohol spinning solution is spray-spun on the wool / chitin mixed fiber by electrospinning. The electrospinning process parameters are: the applied voltage is 50KV, and the spinning nozzle is a needle-free butterfly nozzle. , the receiving distance is 14cm, the spinning temperature is 20°C, the relative humidity of the environment is 45%, the concentration of graphene in the g...

Embodiment 2

[0047] The present embodiment provides a kind of preparation method of multifunctional wool composite yarn, comprises the following steps:

[0048] (1) Nylon 66 is used as the core yarn, and the core yarn is passed through the center of the yarn covering device.

[0049] (2) Assemble 8 groups of wool / chitin mixed fibers on the outer yarn feeding mechanism, and each group consists of three wool / chitin mixed fibers.

[0050] (3) Set the rotating speed of the outer covering yarn feeding mechanism to 90r / min, and cover the wool / chitin mixed fiber clockwise on the core yarn.

[0051] (4) The graphene / polyvinyl alcohol spinning solution is spray-spun on the wool / chitin mixed fiber by electrospinning. The electrospinning process parameters are: the applied voltage is 50KV, and the spinning nozzle is a needle-free butterfly nozzle. , the receiving distance is 14cm, the spinning temperature is 20°C, the relative humidity of the environment is 45%, the concentration of graphene in the ...

Embodiment 3

[0054] The present embodiment provides a kind of preparation method of multifunctional wool composite yarn, comprises the following steps:

[0055] (1) Nylon 66 is used as the core yarn, and the core yarn is passed through the center of the yarn covering device.

[0056] (2) Assemble 10 groups of wool / chitin mixed fibers on the outer yarn feeding mechanism, and each group consists of three wool / chitin mixed fibers.

[0057] (3) Set the rotating speed of the outer covering yarn feeding mechanism to 90r / min, and cover the wool / chitin mixed fiber clockwise on the core yarn.

[0058] (4) The graphene / polyvinyl alcohol spinning solution is spray-spun on the wool / chitin mixed fiber by electrospinning. The electrospinning process parameters are: the applied voltage is 50KV, and the spinning nozzle is a needle-free butterfly nozzle. , the receiving distance is 14cm, the spinning temperature is 20°C, the relative humidity of the environment is 45%, the concentration of graphene in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com