Method for eliminating view blind area of A pillar of vehicle body by using lightweight mirror group and mirror group

A lightweight, mirror group technology, applied in vehicle parts, optical observation devices, transportation and packaging, etc., can solve the problems of airbag popping, hidden dangers, etc., and achieve the effect of increasing safety, reducing inertial force, and avoiding fragmentation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

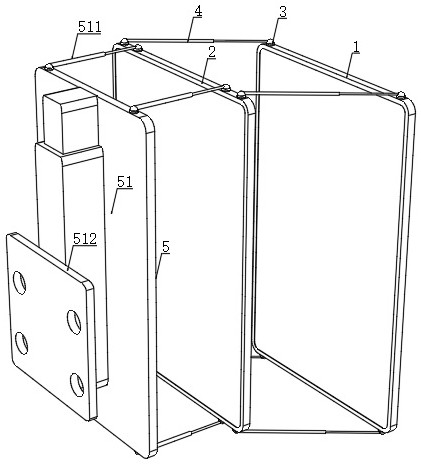

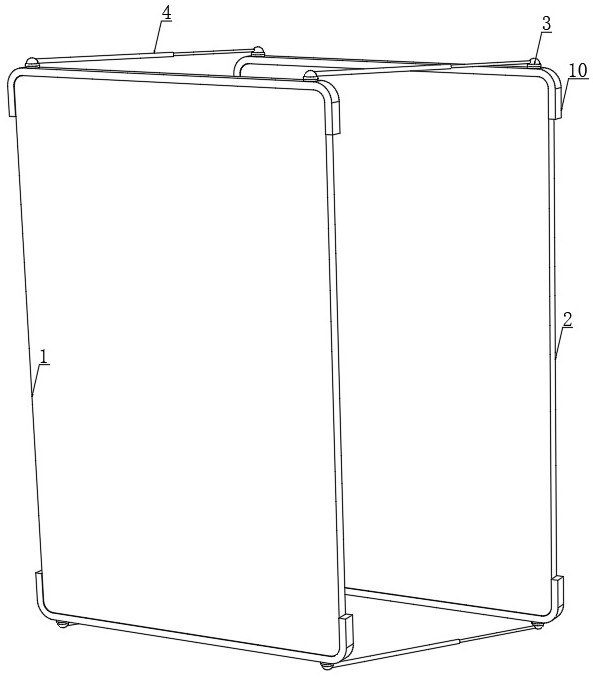

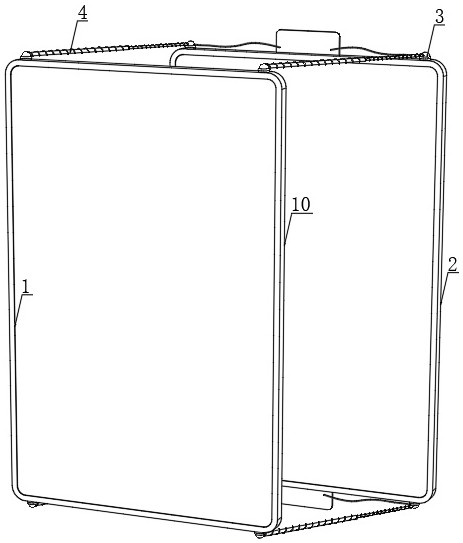

[0031] see Figure 1-5 , the present invention provides the following technical solutions: a method for eliminating the blind area of the A-pillar field of view of the car body by using a lightweight mirror group, comprising the following steps:

[0032] S1, material selection, the mirror solid layer of the mirror group is made of non-metal (non-traditional silicate glass), with high toughness, high strength and lightweight polymer organic material as the main material, of course, it can also be used with anti-crack Glass or a mirror with a thin metal layer as the mirror material;

[0033] S2, mirror group selection, in a small car or off-road vehicle with an airbag on the A-pillar, the total mass of the mirror group is less than 400g, because the first reflector 1 is farther away from the A-pillar, the A-pillar decorative plate has less protective effect on it, The instantaneous inflation of the A-pillar airbag has a greater impact on the first reflector. It is safer to ha...

Embodiment 2

[0050] see Image 6 , the difference technical feature of this embodiment compared with embodiment 1 is: the mirror group adopts two groups, by installing two groups of mirror groups on both sides of the A-pillar to form a composite mirror group, through the composite mirror group Imaging of blind spots can also be realized.

[0051] It should also be added that this method of using mirrors to form images to eliminate blind spots can also be applied to vehicles such as buses, engineering vehicles, trains, ships, and aircrafts. The mirror surface is not limited to flat mirrors, and curved surfaces can also be selected according to needs. For convex mirrors and concave mirrors with a radius greater than 15cm, the second reflector can also be equipped with suction cups, magnetic stickers and Velcro stickers on the back. on the windshield.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com