Full-automatic cosmetic container assembling production line

A technology for assembling production lines and cosmetic containers, which is applied in the field of fully automatic assembly production lines for cosmetic containers, can solve problems such as misoperation of punching switches, low production efficiency, large punching force, etc., and achieve the effects of eliminating safety accidents and improving safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

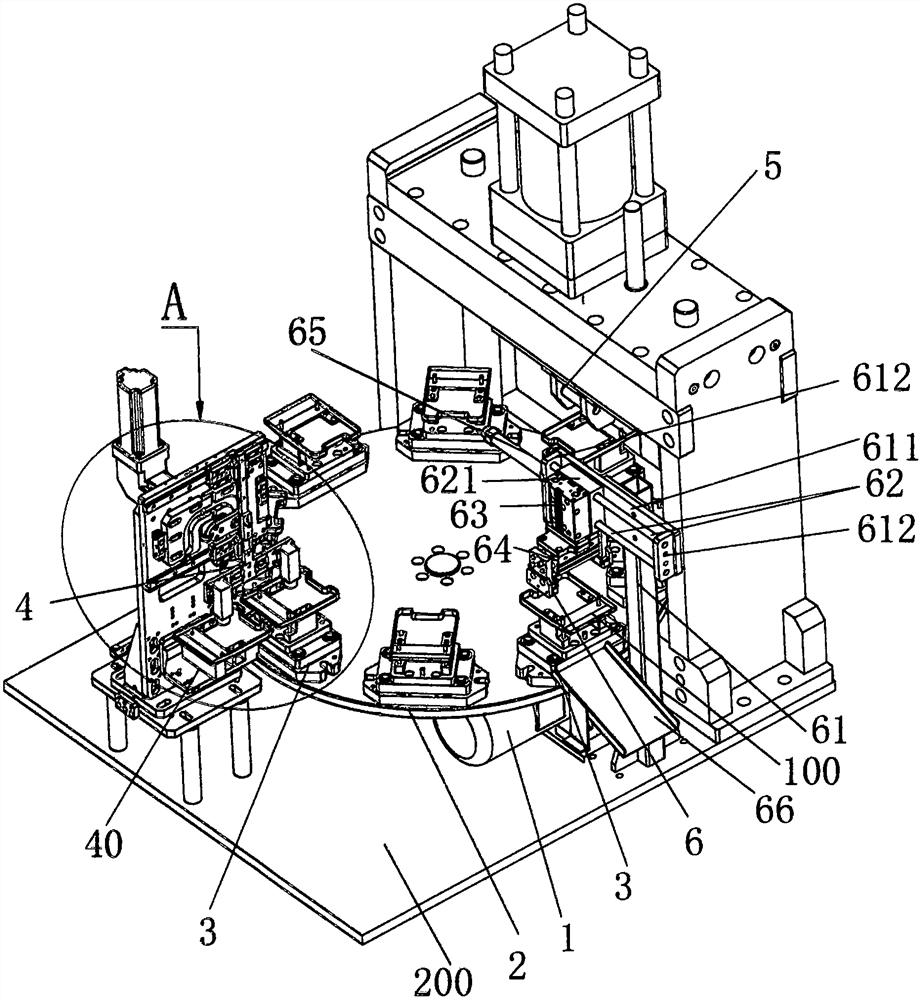

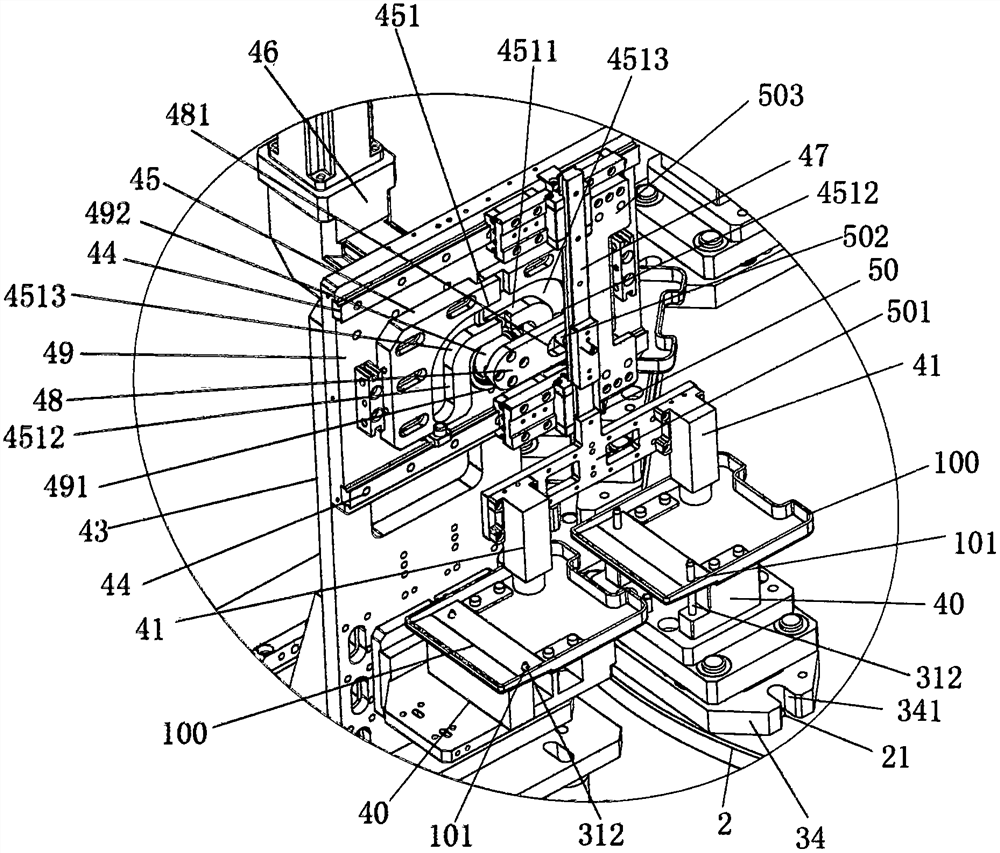

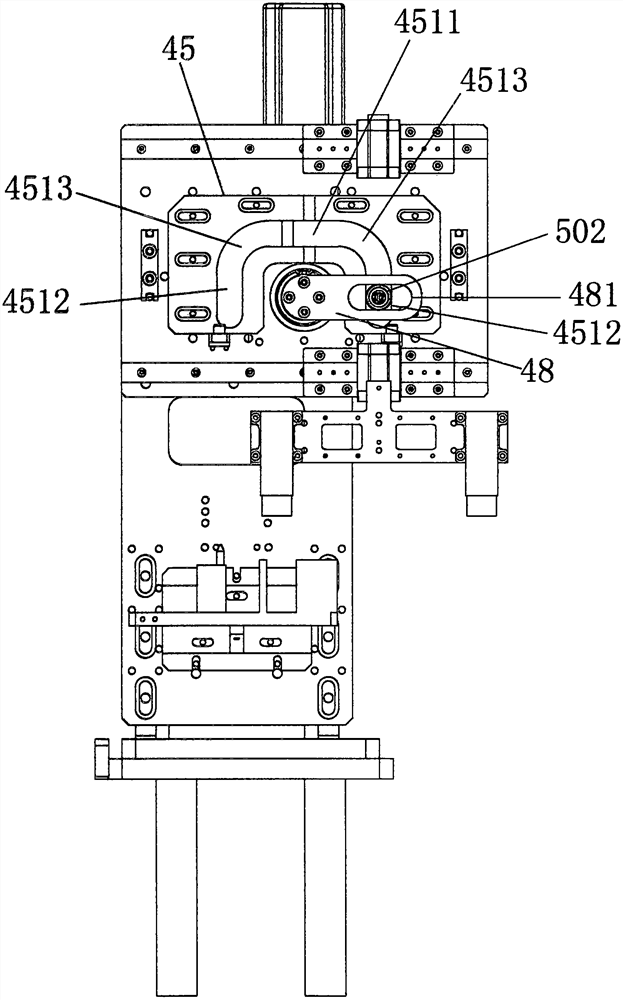

[0020] As shown in the drawings, the cosmetic container automatic assembly line described in this embodiment includes a workbench 200, a rotating plate 2, an indexing drive mechanism 1 that drives the rotating plate 2 to rotate in an indexing manner, and The feeding manipulator 4, the unloading manipulator 6 and the riveting mechanism 5, the rotating plate 2 are provided with eight tooling fixtures 3 in a circular array, and three tooling fixtures 3 in the eight tooling fixtures 3 are respectively located on the feeding manipulator. 4. Below the blanking manipulator 6 and the riveting mechanism 5, the feeding manipulator 4 is located at the loading position 300, which specifically includes a grabbing part (which includes a moving arm 50 and a vacuum chuck 41), a driving mechanism 46, a track groove 451, Be fixed on the loading frame 43 on the workbench 200, the base plate 49, the swing arm 48, the vertical linear guide rail 47, and the driving plate 45 and the horizontal linear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com