Automatic special riveting machine for motor heat sink

A motor cooling, fully automatic technology, applied in the field of fully automatic special riveting machines for motor heat sinks, can solve the problems of low processing efficiency, insufficient operation safety, unstable riveting strength, etc., to improve the success rate, stable and reliable feeding, Guaranteed effect of stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

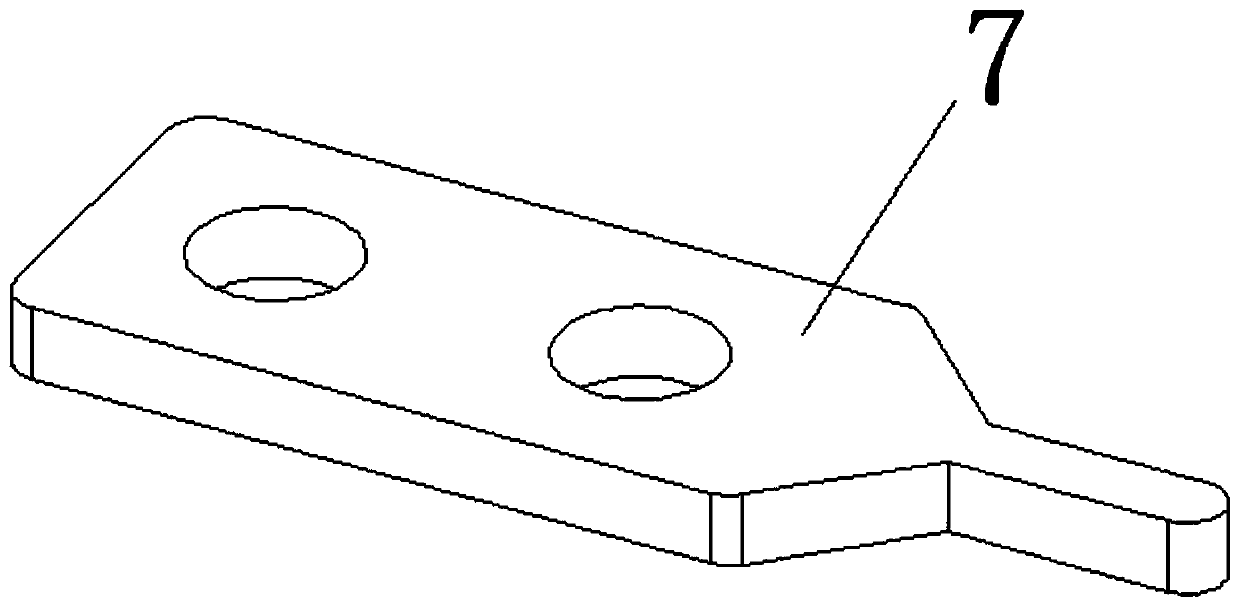

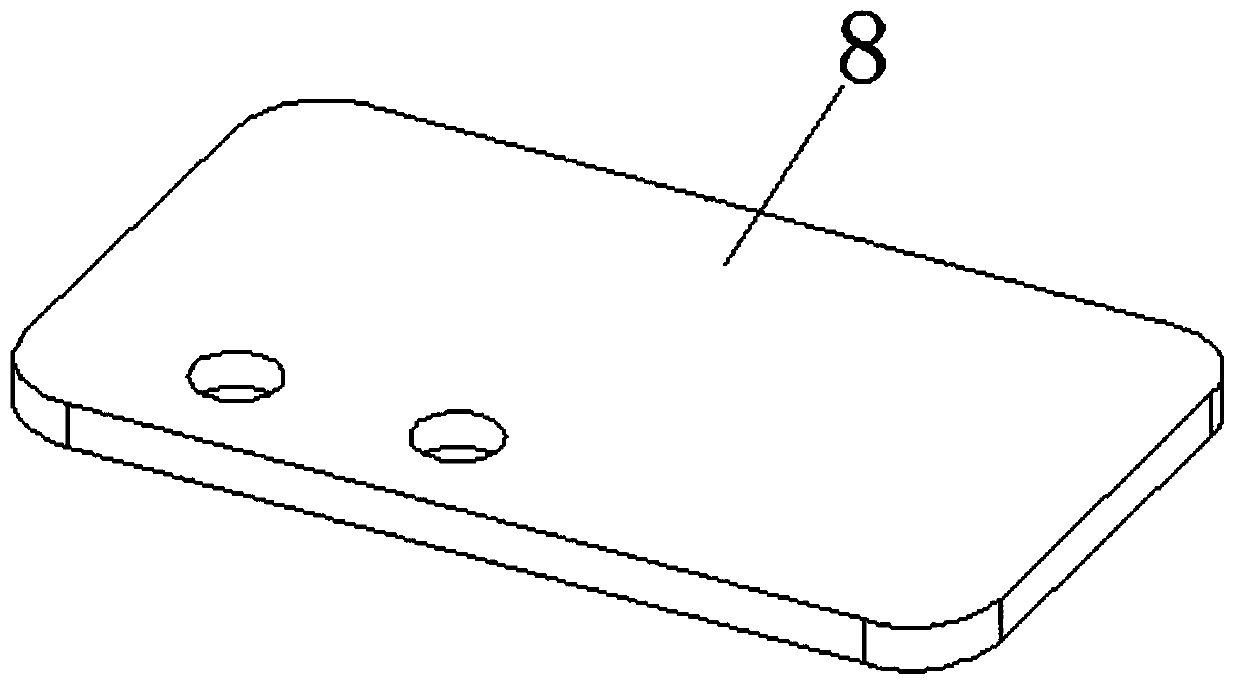

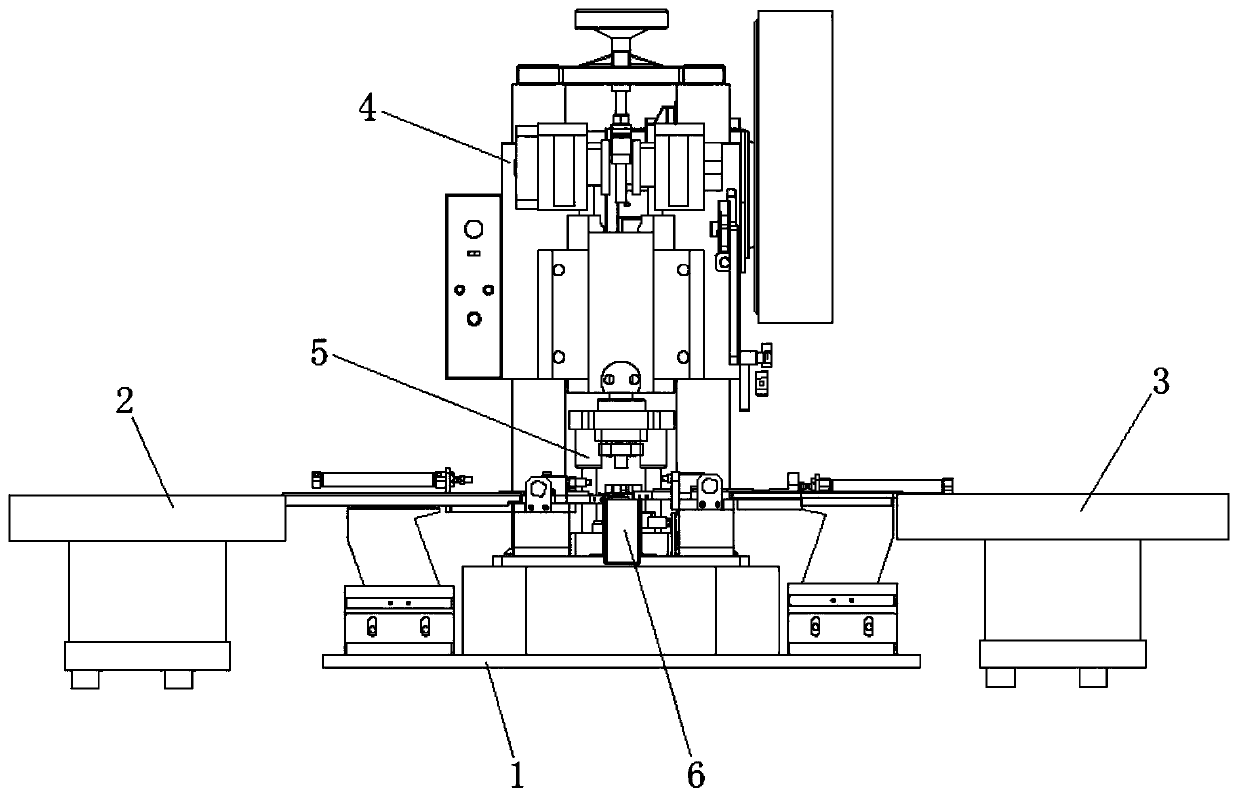

[0046] See Figure 3 to Figure 15 , The fully automatic riveting machine for motor cooling fins of this embodiment includes a platen 1, a workpiece feeding mechanism 2, a workpiece feeding mechanism 3, an electric punch 4, a riveting mechanism 5 and a discharging mechanism 6.

[0047] Electric punch press 4 is fixed on the platen 1. The riveting mechanism 5 is installed on the electric punch press 4 . The A workpiece feeding mechanism 2 and the B workpiece feeding mechanism 3 are arranged on both sides of the riveting mechanism 5 respectively, and send the A workpiece 7 and the B workpiece 8 to the riveting mechanism 5 respectively. The discharge mechanism 6 is installed on the electric punch 4, and pushes out the riveted heat sink from the riveting mechanism 5 .

[0048] A workpiece feeding mechanism 2 includes a first vibrating plate 21, a first linear vibrating feeder 22, a first straight vibration adjustment seat 23, a first vertical pushing assembly 24, a first horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com