Book single-page continuous stamping device

A single-page and punching technology for books, applied in metal processing and other directions, can solve the problems of long production cycle, punching of different pages, easy injury, etc., to achieve the effect of improving efficiency, reducing labor costs, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

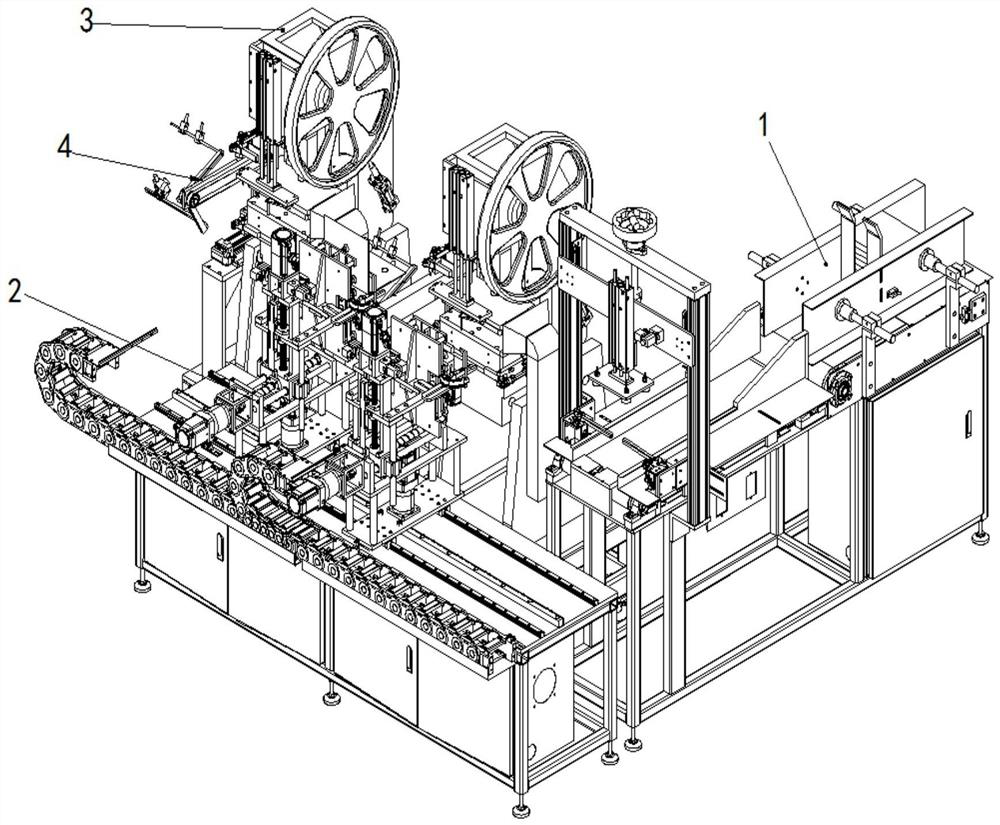

[0059] Such as figure 1 As shown, the present invention discloses a continuous punching device for a single page of a book, including a feeding device 1, a material grabbing and conveying device 2, a punching device 3 and a page turning device 4, the feeding device 11 and the punching device 3 are arranged in parallel, and the grasping The material conveying device 2 is located at the front end of the feeding device 1 and the punching device 3 , and the page turning device 4 is arranged on the side of the punching device 3 .

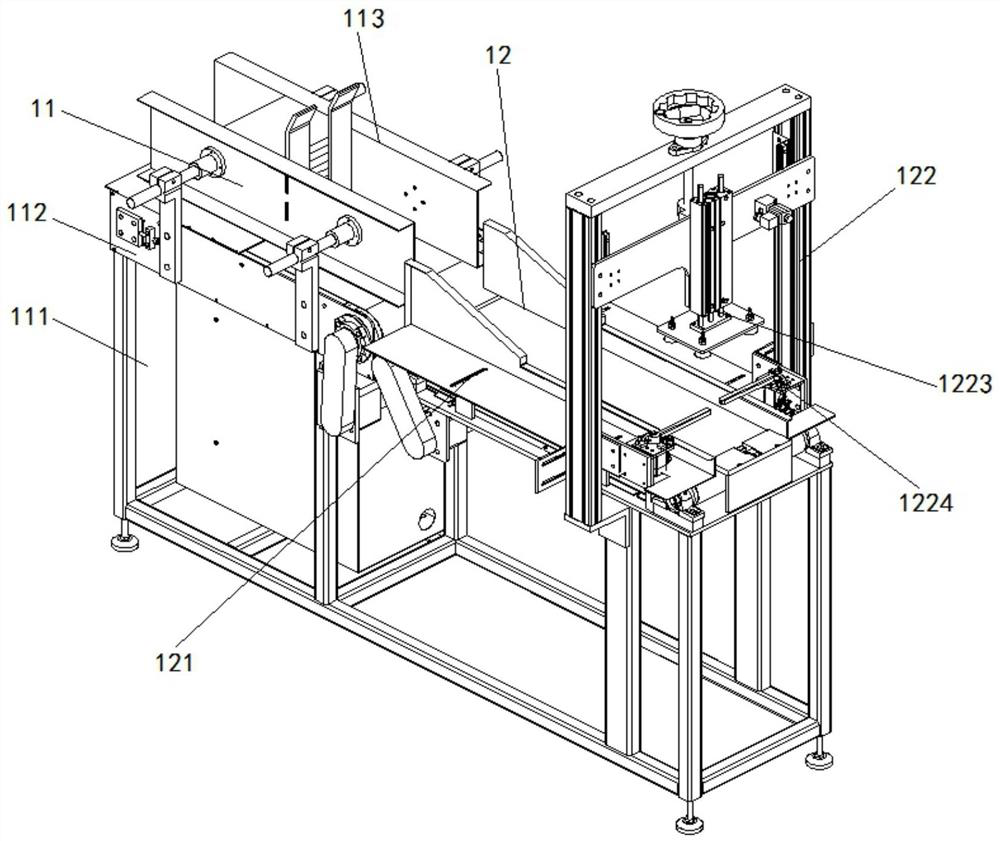

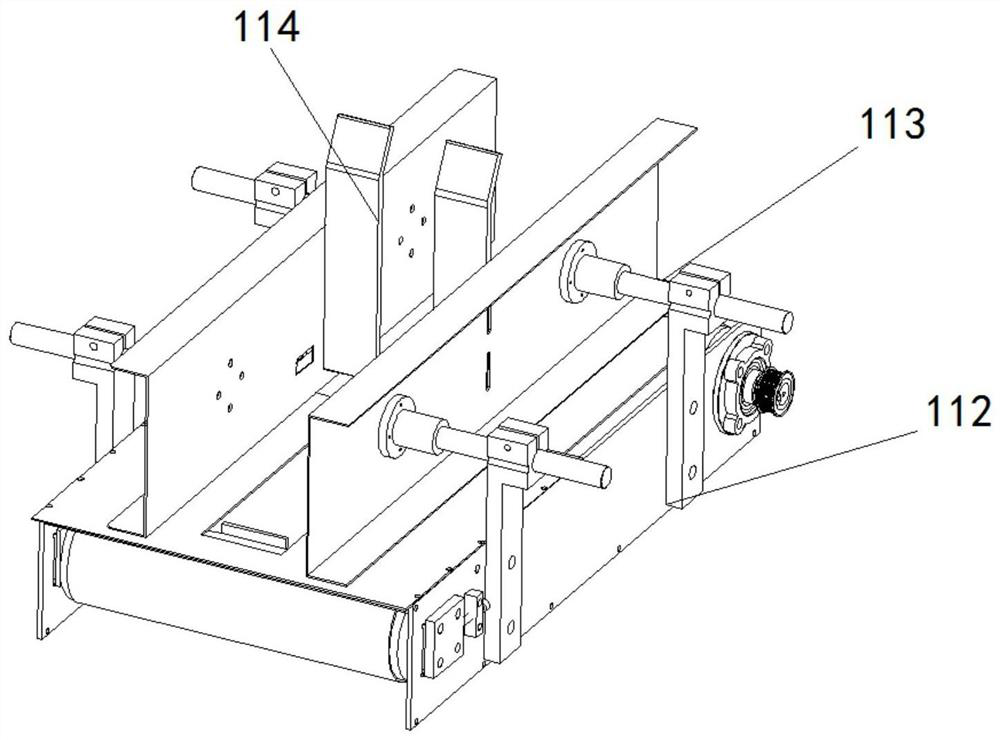

[0060] Such as figure 2 As shown, the feeding device 1 is used to transport the books that need to be punched to a designated position. The feeding device 1 includes a storage and conveying device 11 and a suction conveying device 12. The storage and conveying device 11 is used to transport the books that need to be punched to Suction material conveying device 12, material storage conveying device 11 comprises material storage conveying frame 111, mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com