High-speed dispersing device for building paint processing and operation method of high-speed dispersing device

A high-speed dispersing device and paint technology, applied in chemical instruments and methods, mixers with rotating stirring devices, transportation and packaging, etc., can solve the problems of waste, pollution, easy residual paint on stirring blades and disturbance plates, etc., and achieve convenience cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

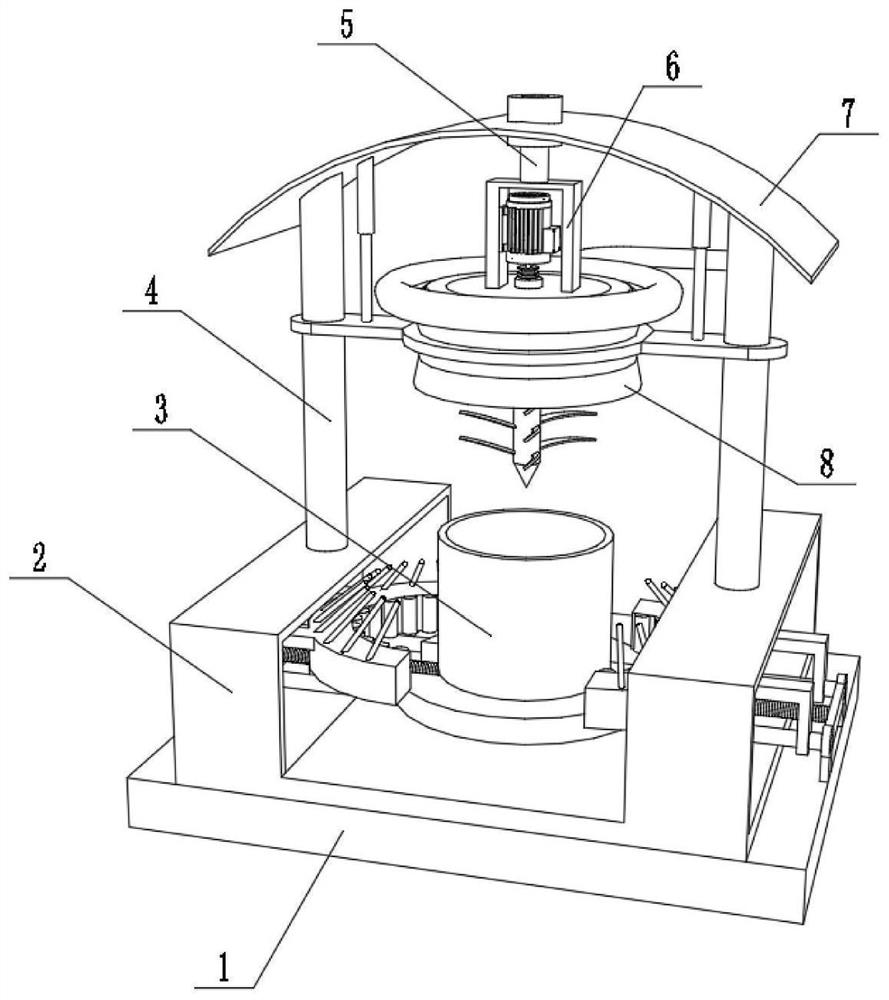

[0040] A high-speed dispersion device for architectural paint processing, such as figure 1 and 4 As shown, it includes a base 1 and a paint bucket 3. The outer wall of the top of the base 1 is fixed with a sliding frame 22 by a lifting assembly, and the inner wall of the top of the sliding frame 22 is provided with a round mouth. The side outer walls are respectively welded with fixed cover two 27 and fixed cover one 8, the opening diameter at the bottom of the fixed cover one 8 is greater than the opening diameter of the paint bucket 3, the inner wall of the fixed cover one 8 is provided with two or more upper limit components, and the fixed cover two 27 top The inner wall is provided with four evenly distributed blowing outlets, the inner wall of the blowing outlet is clamped with a blowing plate 26 inclined downward, the inner wall of one side of the blowing plate 26 is provided with a protective net 24, and the outer wall of the top of the sliding frame 22 is clamped with ...

Embodiment 2

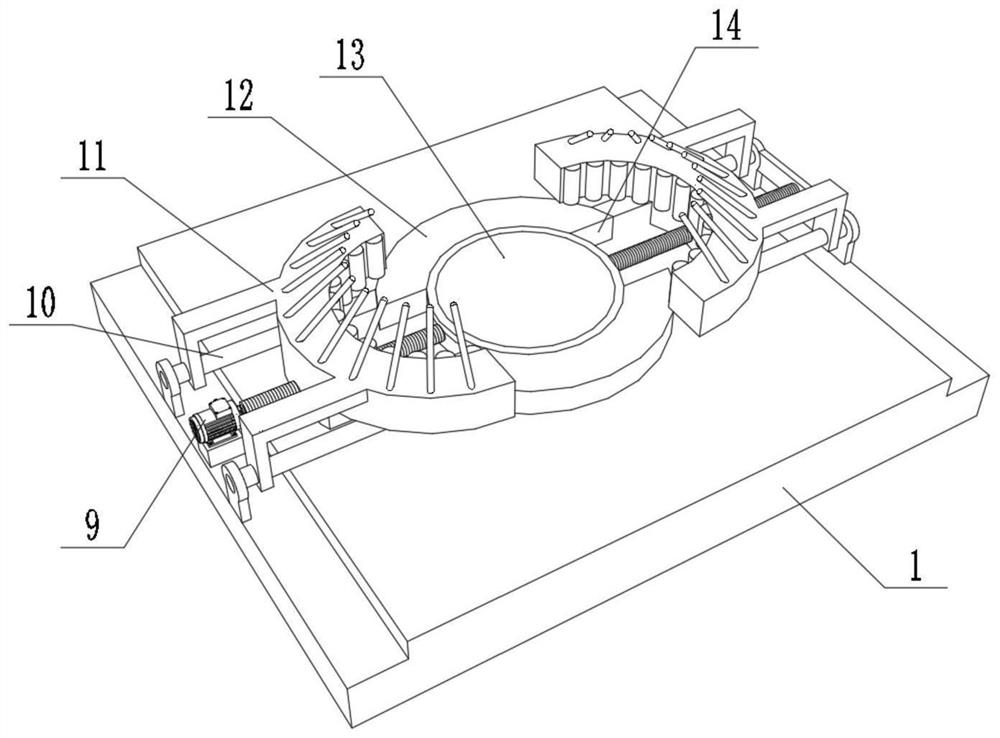

[0046] A high-speed dispersion device for architectural paint processing, such as figure 1 , 2 As shown in and 3, in order to solve the problem of fixing the bottom of the paint bucket 3; this embodiment makes the following improvements on the basis of embodiment 1: the outer wall of the top of the base 1 is welded with a placement platform 12, and the outer wall of the top of the placement platform 12 is provided with a placement area 13. The placement area 13 is located directly below the round opening on the top inner wall of the sliding frame 22, the paint bucket 3 is placed on the top outer wall of the placement area 13, the outer wall on one side of the placement table 12 is rotatably connected with a threaded rod, and the top outer wall of the base 1 is fixed with a motor by bolts. 9. The output shaft of the motor one 9 is connected to the threaded rod through a coupling, and two fixing frames 11 are respectively threaded on both sides of the outer wall of the threaded ...

Embodiment 3

[0049] A method for operating a high-speed dispersion device for architectural paint processing, comprising the steps of:

[0050] S1: Place the paint bucket 3 on the placement area 13 on the placement table 12, then start the motor 9 to drive the threaded rod to rotate, so that the two fixing frames 11 move towards the direction of the paint bucket 3, thereby completing the fixing;

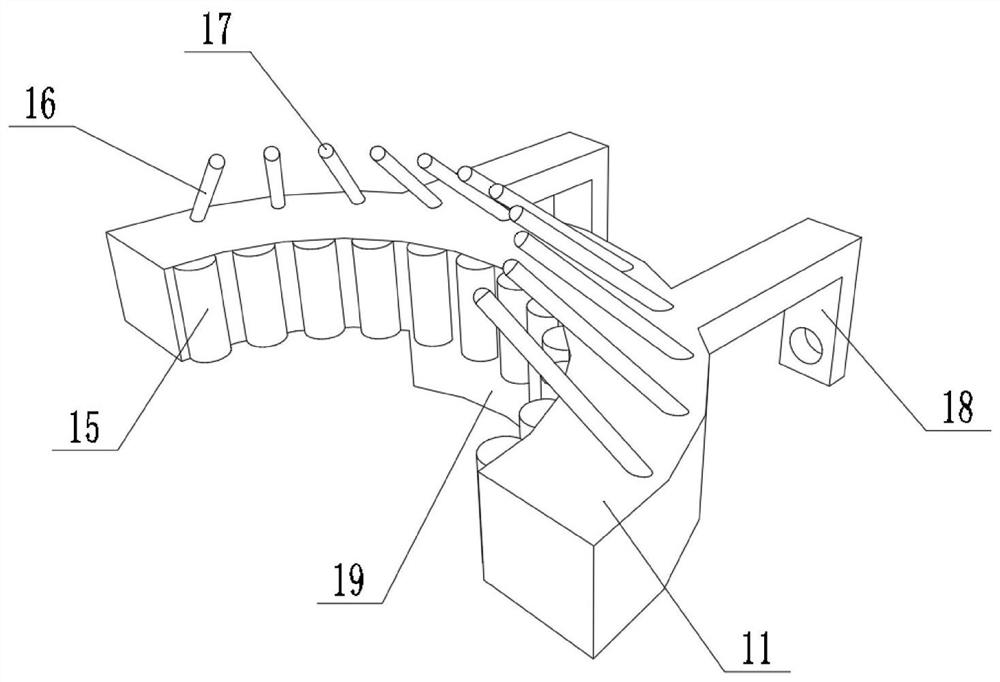

[0051] S2: The anti-slip pad 15 provided on the fixed frame 11 plays an anti-slip effect, and the elastic rods 16 are all inclined towards the center of the circle, and the paint bucket 3 is further fixed, and the soft pad 17 can prevent the elastic rod 16 from scratching the paint bucket 3;

[0052] S3: Control the two electric telescopic rods 20 to move down the sliding frame 22, so that the fixed cover 18 is stuck on the top of the paint bucket 3, and then the arc-shaped elastic plate 23 is deformed to generate a reverse force, and the paint bucket 3 is fixed. The spring 28 increases the elast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com