Nanofiber membrane for chromatography and preparation process thereof

A nanofiber membrane and preparation technology, which is applied in the field of nanofiber membrane and its preparation technology for chromatography, can solve problems such as difficult handling, membrane deformation, and insufficient mechanical strength of the membrane, and achieve the effect of improving the surface strength of the membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

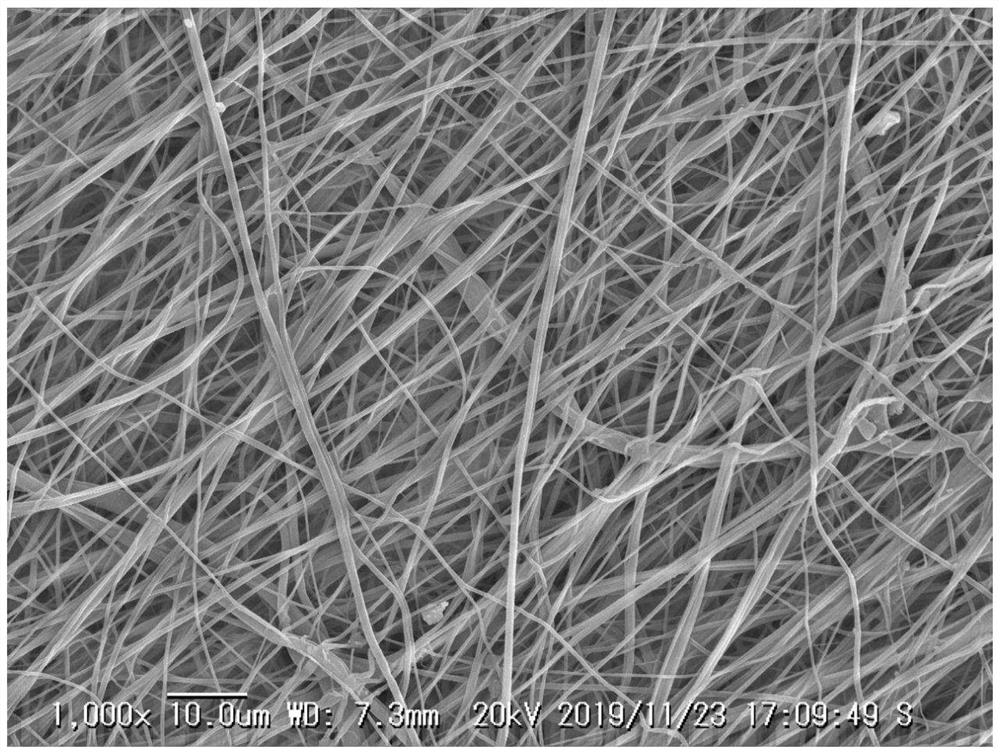

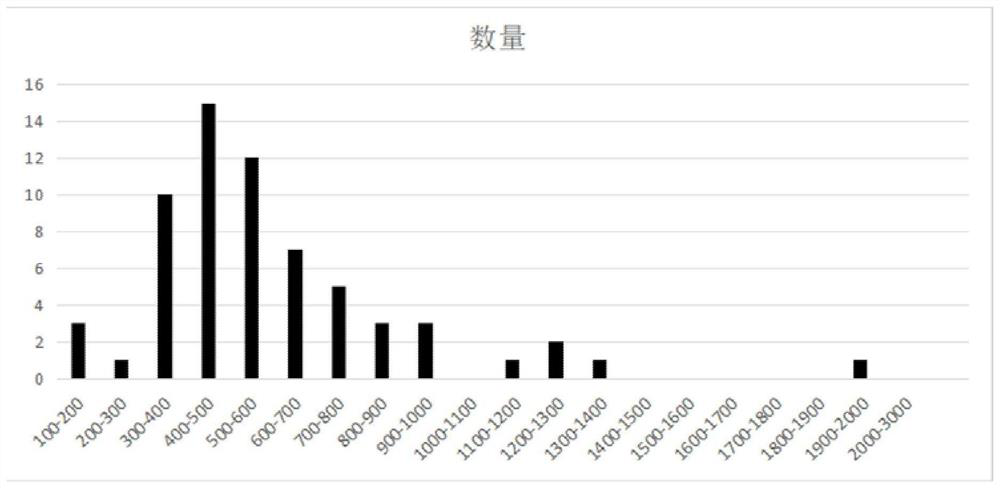

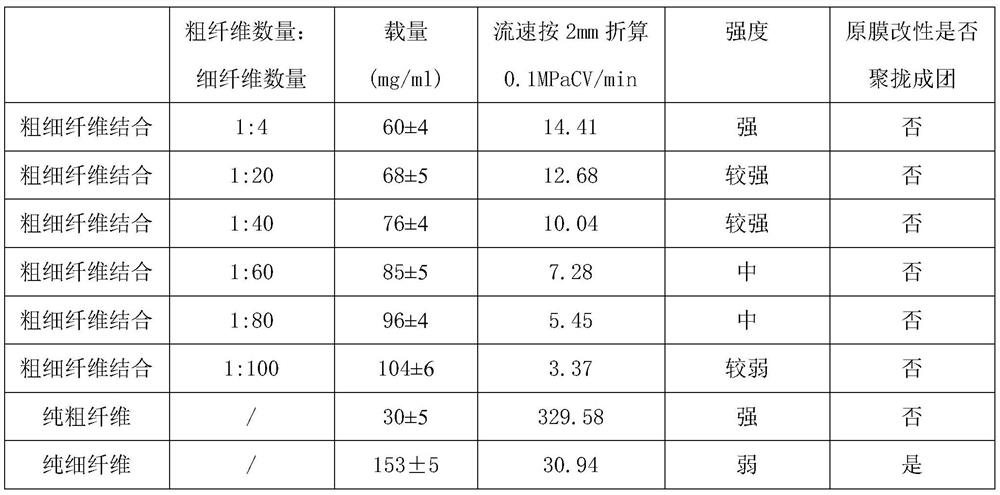

[0038] A nano-PES fiber membrane used for chromatography, where the original membrane material of the nano-fiber membrane is selected as PES material. In other embodiments, the original film can be acetate fiber material, polyester fiber material, etc., but the selected raw materials are different, and they are all similar in terms of fiber structure. The structure of this nano-PES fiber membrane is observed through an electron microscope, and it is found that the membrane is composed of a number of nanometer-scale fine PES fibers intertwined randomly and disorderly. However, we have limited the thickness and diameter of these nanometer-level fibers, and these nanofibers are roughly divided into two groups, one group is thick fibers, and the other group is thin fibers. The diameter of the thick fiber is greater than 1100 nanometers, and the diameter of the thin fiber is less than 1000 nanometers. In the production process of the PES fiber original film, the diameter of the th...

Embodiment 2

[0048] A nanometer cellulose acetate membrane used for chromatography, where the original membrane material of the nanofiber membrane is selected as cellulose acetate. The structure of this nano-cellulose acetate film is observed through an electron microscope, and it is found that the film is composed of a number of nano-scale fine cellulose acetate fibers intertwined randomly and disorderly. Similarly, we have limited the thickness and diameter of these nanometer-level fibers, and these nanofibers are roughly divided into two groups, one group is thick fibers, and the other group is thin fibers. The diameter of the thick fiber is greater than 1100 nm, and the diameter of the thin fiber is less than 1000 nm. In the production process of nano-cellulose acetate original film, the diameter of thick and thin fibers can be controlled by controlling the diameter of the nozzle, and the number of thick and thin fibers can also be controlled by controlling the spraying time to form th...

Embodiment 3

[0051] A kind of technique of preparing nanometer PES fiber film, comprises the following steps:

[0052] S1: Select the fiber original film, the selected nano-PES fiber original film is interwoven with thick fibers and thin fibers, and the diameter of the thick fiber is greater than 1100 nanometers, and the diameter of the thin fiber is less than 1000 nanometers; further select the nano-PES fiber original film The ratio of the number of thick fibers to thin fibers is limited, and the ratio of the number of thick fibers to thin fibers is set between 1:5-1:100, preferably between 1:15-1:50. In the original nano-PES membrane, thick fibers can play a strong enough supporting strength, and thin fibers can ensure that the subsequent finished nano-PES fiber membrane has a large enough surface area for chromatography.

[0053] S2: immerse the fibrous original membrane in the pre-wetting solution, and wet the fibrous original membrane until the fibrous original membrane becomes transp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com