Intelligent lubricating system for coal mine belt conveyor and intelligent grease injection method

A belt conveyor and lubrication system technology, applied in engine lubrication, conveyor, transportation and packaging, etc., can solve problems such as no feedback lubrication adjustment, lack of network communication function, blockage alarm sensor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the invention.

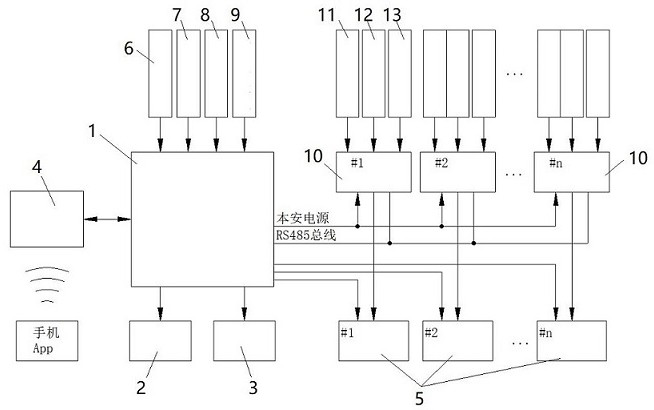

[0038] see figure 1 , the present invention relates to an intelligent lubrication system for a coal mine belt conveyor, comprising a sensor part, an oil circuit controller part, a smart box part, a PLC control box 1 and a monitoring system upper computer 4;

[0039] The PLC control box 1 is respectively connected with the grease filling pump 2 and the grease injection pump 3, and is used to control the grease filling pump 2 and the grease injection pump 3, and the grease filling pump 2 and the grease injection pump 3 cooperate to complete the grease injection on the lubricated object; see Figure 6-7 , PLC control box 1 adopts flameproof and intrinsically safe ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com