Box type automatic cold spraying equipment

A technology of automatic cold and spraying equipment, which is applied in coating, metal material coating process, pressure inorganic powder coating, etc. It can solve the problems of difficult tubular materials, low powder utilization rate, and reduced coating performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

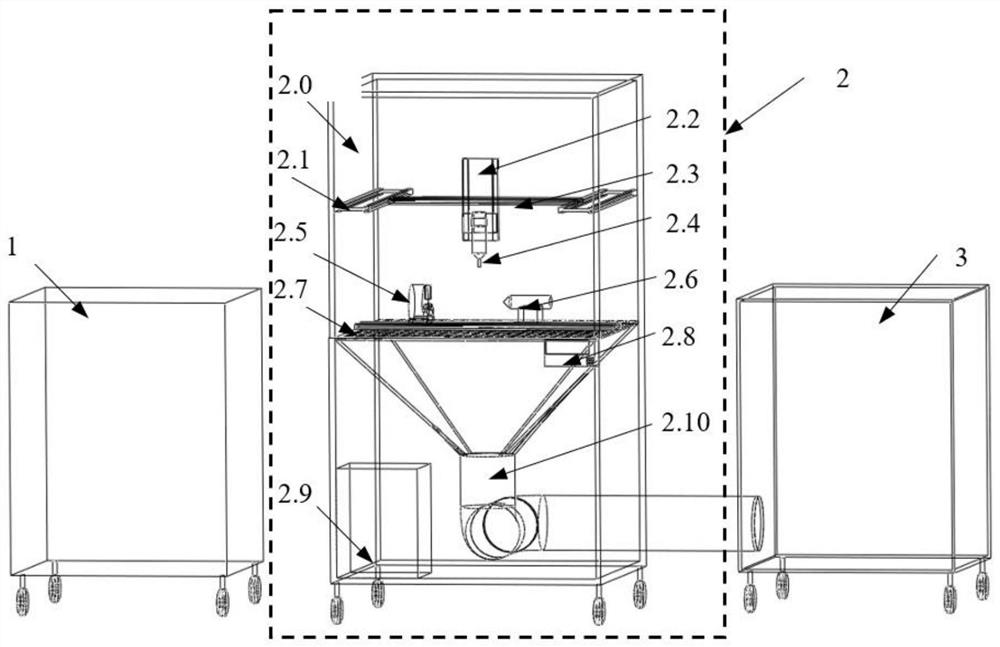

[0032] Such as figure 1 As shown, a box-type automatic cold spraying equipment in this example includes: an air compressor 1 , a cold spraying unit 2 and a powder recoverer 3 .

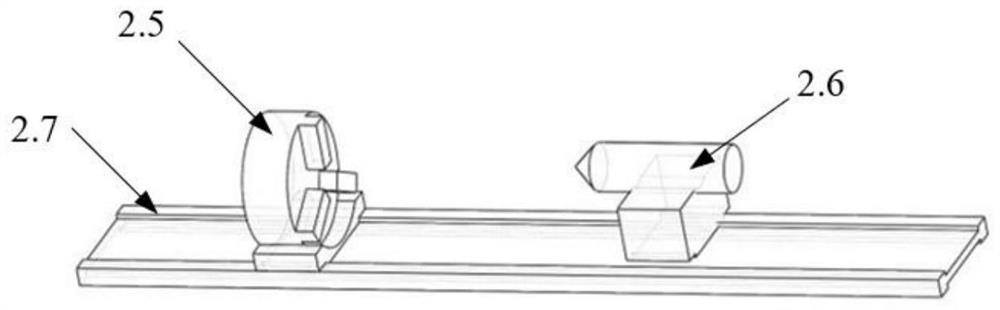

[0033] Further, the cold spray unit 2 includes: box body 2.0, X-axis slide rail 2.1, Z-axis slide rail 2.2, Y-axis slide rail 2.3, spray gun 2.4, left rotor 2.5, right rotor 2.6, bottom slide rail 2.7, control Device 2.8, powder feeder 2.9, powder recovery tube 2.10.

[0034] Furthermore, the X-axis slide rail 2.1, the bottom slide rail 2.7, the controller 2.8, the powder feeder 2.9 and the powder recovery pipe 2.10 are respectively fixed inside the box body 2.0.

[0035] Furthermore, the Y-axis slide rail 2.3 is fixed on the slide block of the X-axis slide rail 2.1, the Z-axis slide rail 2.2 is fixed on the slide block of the Y-axis slide rail 2.3, and the spray gun 2.4 is fixed on the slide block of the Z-axis slide rail 2.2 superior.

[0036] Furthermore, the spray gun 2.4 is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com