Waterborne polyurethane structure color waterproof coating material, preparation method and application thereof

A water-based polyurethane and waterproof coating technology, which is applied in polyurea/polyurethane coatings, paper coatings, coatings, etc., can solve the problems of complex preparation process and insufficient waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

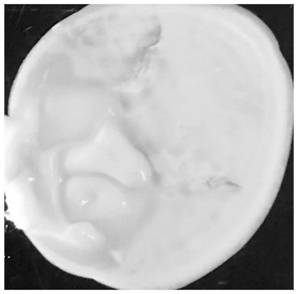

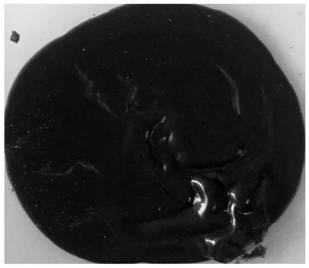

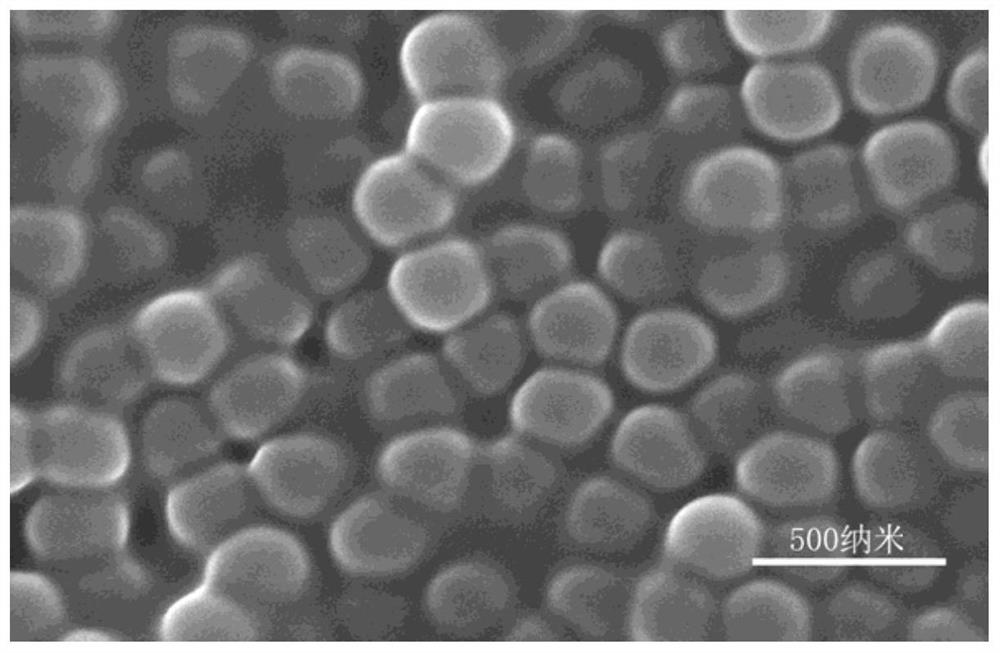

[0038] 1. Take 0.35 parts by weight of methacrylic acid and 15 parts by weight of styrene and disperse them in deionized water; add 0.2 parts by weight of ammonium persulfate after heating and stirring to 78°C; keep stirring at 78°C overnight. After the crude product is obtained, it is purified to obtain the product; it is centrifuged and concentrated to obtain submicron polystyrene microspheres with an average particle diameter of 210 nm.

[0039] 2. A water-based polyurethane structural color waterproof coating, comprising the following components: 210nm polystyrene microspheres, carbon black and water-based polyurethane emulsion, the mass ratio of 210nm polystyrene microspheres, carbon black and water-based polyurethane emulsion is 210nm polystyrene Ethylene microspheres: carbon black: water-based polyurethane emulsion=1:0.01:3; the mass ratio of water-based polyurethane to water in the water-based polyurethane emulsion is 1:3.

[0040]The above-mentioned 210nm polystyrene ...

Embodiment 2

[0044] 1. Take 0.35 parts by weight of methacrylic acid and 10 parts by weight of styrene and disperse them in deionized water; add 0.2 parts by weight of ammonium persulfate after heating and stirring to 78°C; keep stirring at 78°C overnight. After the crude product is obtained, it is purified to obtain the product; it is centrifuged and concentrated to obtain submicron polystyrene microspheres with an average particle diameter of 180 nm.

[0045] 2. A water-based polyurethane structural color waterproof coating, comprising the following components: 180nm polystyrene microspheres, carbon black and water-based polyurethane emulsion, the mass ratio of 180nm polystyrene microspheres, carbon black and water-based polyurethane emulsion is 180nm polystyrene Ethylene microspheres: carbon black: water-based polyurethane emulsion=1:0.01:3; the mass ratio of water-based polyurethane to water in the water-based polyurethane emulsion is 1:3.

[0046] The above-mentioned 180nm polystyrene...

Embodiment 3

[0050] 1. Take 0.35 parts by weight of methacrylic acid, 15 parts by weight of styrene and 0.025 parts by weight of sodium lauryl sulfate, and disperse them in deionized water; add 0.2 parts by weight of ammonium persulfate after heating and stirring to 78°C; keep stirring at 78°C overnight. After the crude product is obtained, it is purified to obtain the product; it is centrifuged and concentrated to obtain submicron polystyrene microspheres with an average particle diameter of 130 nm.

[0051] 2. A water-based polyurethane structural color waterproof coating, comprising the following components: 130nm polystyrene microspheres, carbon black and water-based polyurethane emulsion, the mass ratio of 130nm polystyrene microspheres, carbon black and water-based polyurethane emulsion is 130nm polystyrene Ethylene microspheres: carbon black: water-based polyurethane emulsion=1:0.01:3; the mass ratio of water-based polyurethane to water in the water-based polyurethane emulsion is 1:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com