Self-rotating type heat shield rapid cleaning device and using method

A cleaning device and spin-type technology, which is applied in chemical instruments and methods, cleaning methods and utensils, self-melting liquid pulling method, etc., can solve the problem of silicon powder adhesion and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described below with reference to the accompanying drawings.

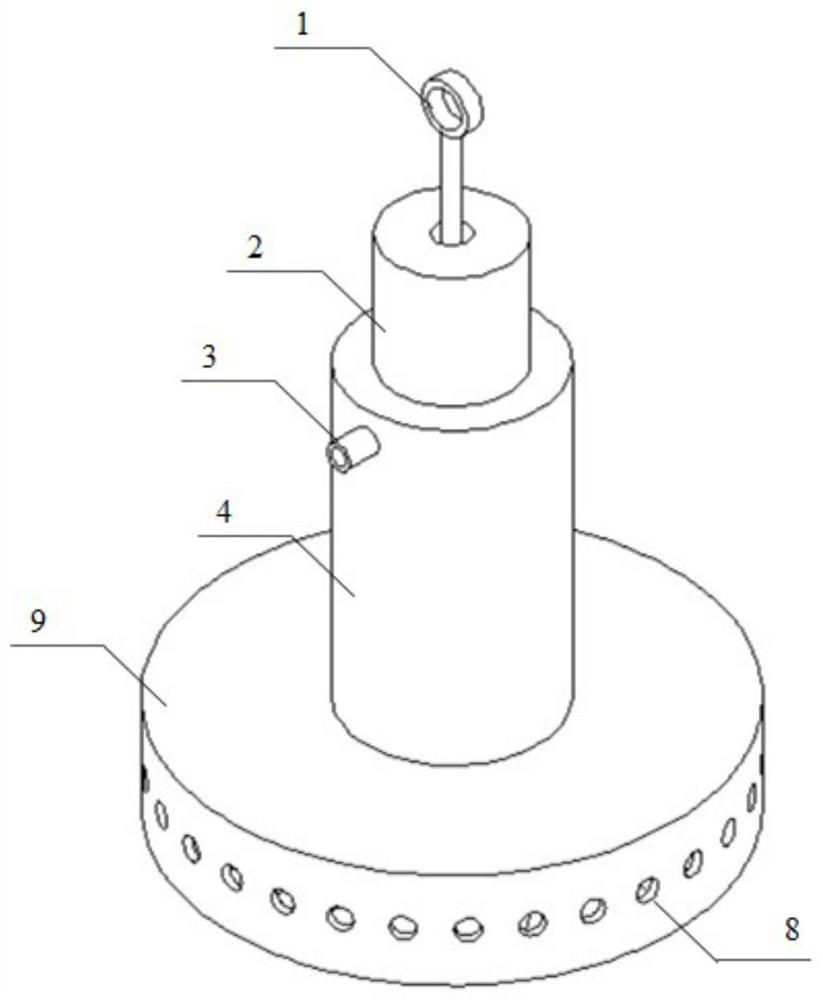

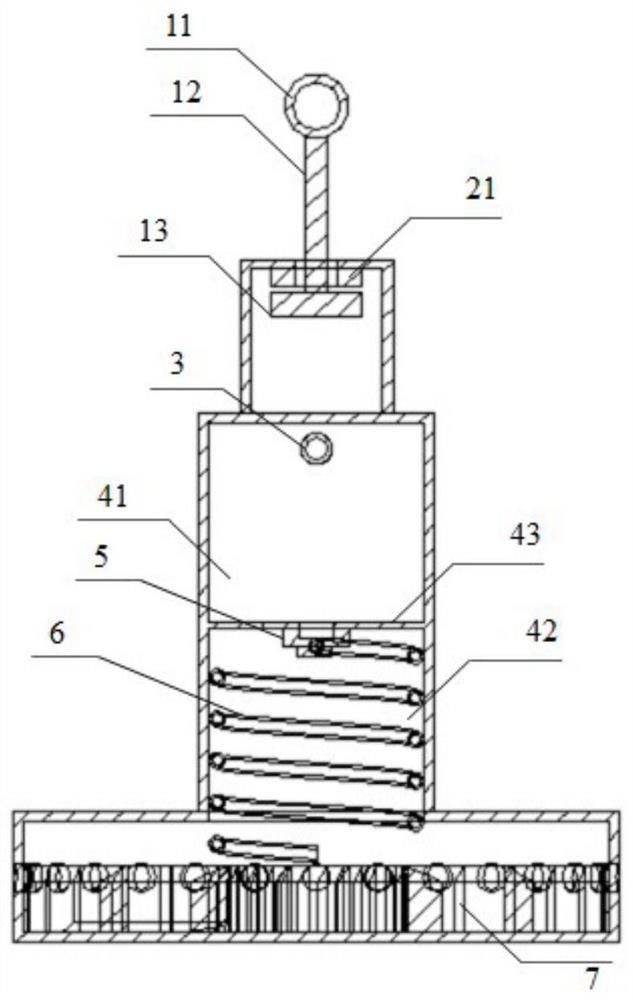

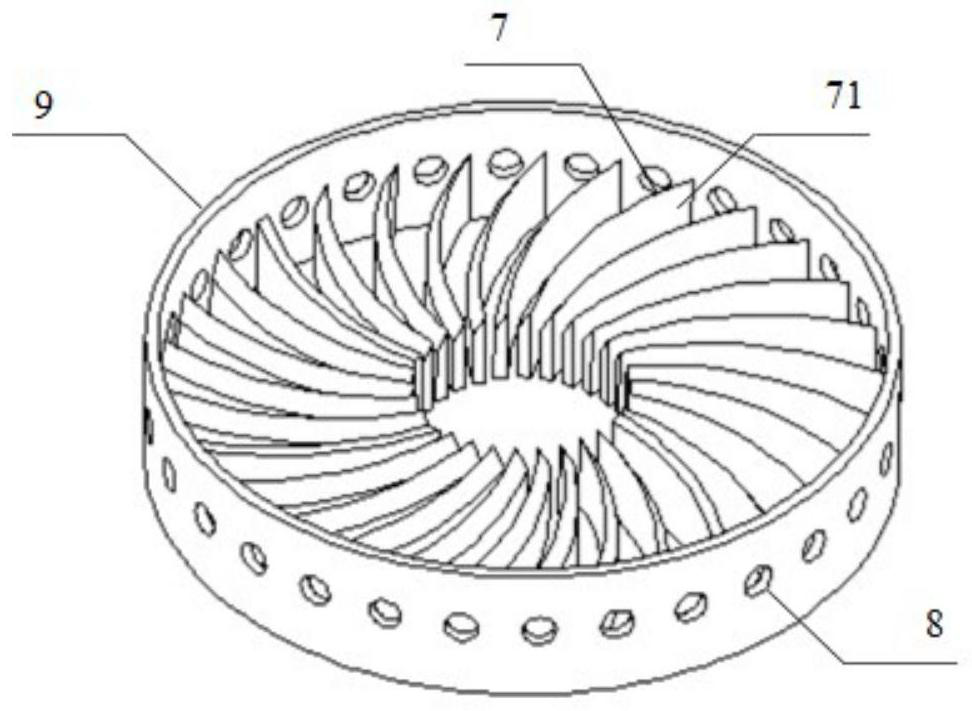

[0024] Such as Figure 1-4 As shown, the first embodiment of the present invention discloses a spin-type heat shield rapid cleaning device, a hook assembly 1, a first cavity 2, a second cavity 4 and a third cavity 9, the hook assembly 1 runs through the first One end face of a cavity 2 is rotationally connected with the first cavity 2; the other end face of the first cavity 2 is fixedly connected with an end face of the second cavity 4, and the first cavity 2 and the second The chamber 4 is isolated; the other end face of the second chamber 4 is fixedly connected with an end face of the third chamber 9; the second chamber 4 includes an argon chamber 41, an exhaust chamber 42 and a The partition 43 between the argon chamber 41 and the exhaust chamber 42; the side of the argon chamber 41 is fixedly connected with the intake valve 3, and the exhaust chamber 42 commu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com