Display module, thinning method of display panel, display panel and display device

A display module and display panel technology, which is applied in the input/output process of data processing, the manufacture/processing of organic semiconductor devices, instruments, etc., can solve the problems of product touchability and electrical failure, affecting product preparation yield, and poor corrosion of TSP and other problems, to prevent acid seepage, simplify the number of glue coating and curing, and improve the effect of edge sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

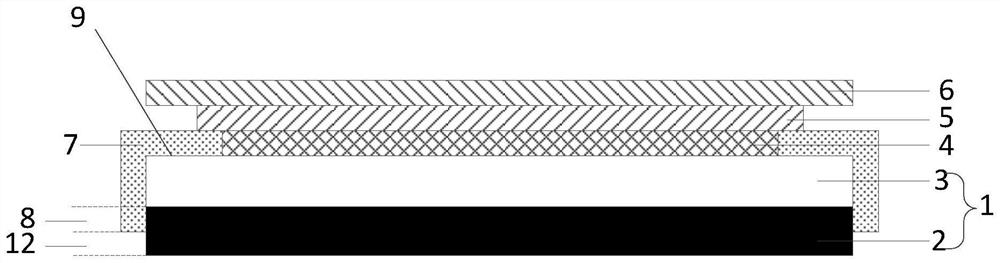

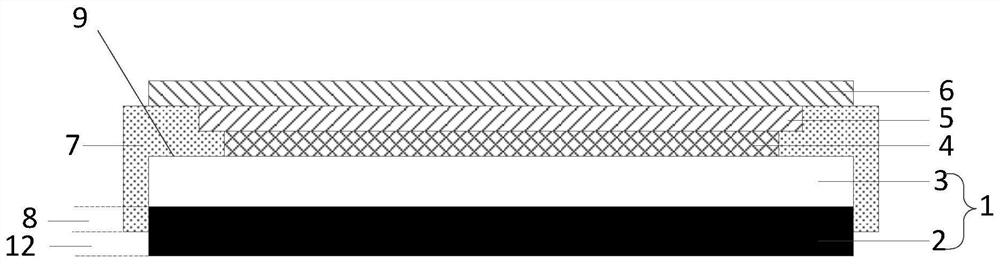

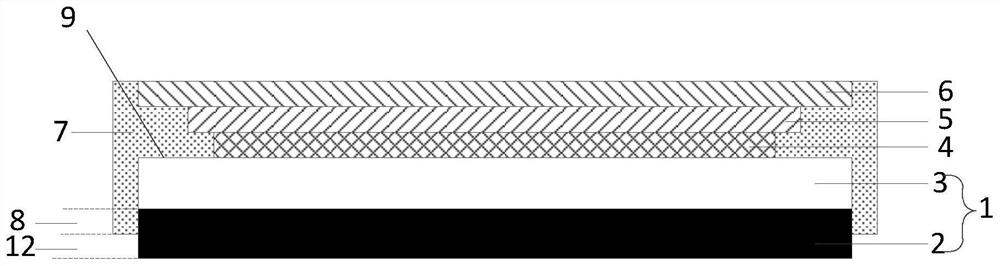

[0051] The embodiment of the present application provides a display module, such as figure 1 As shown, the display module includes: a display panel 1, a protective film 4 on the to-be-protected surface 9 of the display panel 1, a first acid-resistant film 5 located on the protective film 4, located on the the second acid-resistant film 6 on the first acid-resistant film 5, and the sealant 7;

[0052] The display panel 1 includes: a substrate to be thinned 2 and a touch substrate 3 disposed oppositely; the surface to be protected 9 is the surface of the touch substrate 3 facing away from the substrate to be thinned 2 , and the to-be-thinned substrate 2 The substrate is divided into a to-be-thinned area 12 and a non-thinned area 8;

[0053] The protective film 4 covers part of the surface to be protected 9;

[0054] The orthographic projection of the first acid-resistant film 5 on the surface to be protected 9 falls into the surface to be protected 9 , and the protective film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com