High-performance silicon carbide semiconductor field effect transistor structure

A field-effect transistor and high-performance silicon carbide technology, which is applied in the field of high-performance silicon carbide semiconductor field-effect transistor structure, can solve the problems of unfixed wiring, inconvenient maintenance, and low electrode hardness, and achieve simple and convenient opening and closing, and easy maintenance , Reasonable effect of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

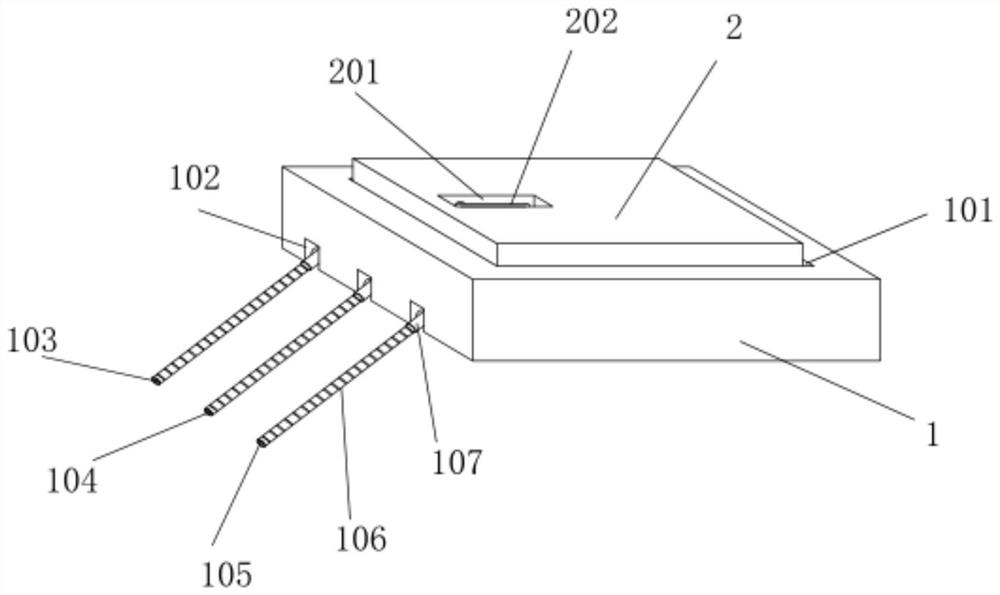

[0035] see Figure 1-2, in an embodiment of the present invention, a high-performance silicon carbide semiconductor field effect transistor structure includes a field effect transistor body, the field effect transistor body includes a field effect transistor base 1 and a field effect transistor outer cavity 2, and the field effect transistor The outer cavity 2 is fastened on the top surface of the field effect transistor base 1, and several groups of wiring frames 3 are arranged between the field effect transistor base 1 and the field effect transistor outer cavity 2. One side of the field effect transistor base 1 Three rotating slots 102 are provided, and the insides of the three rotating slots 102 are respectively provided with a hinge shaft 108, and a T-shaped connecting frame 107 is rotatably connected to the hinge shaft 108, and one side of the field effect transistor base 1 A transistor collector 103, a transistor base 104, and a transistor emitter 105 are respectively p...

Embodiment 2

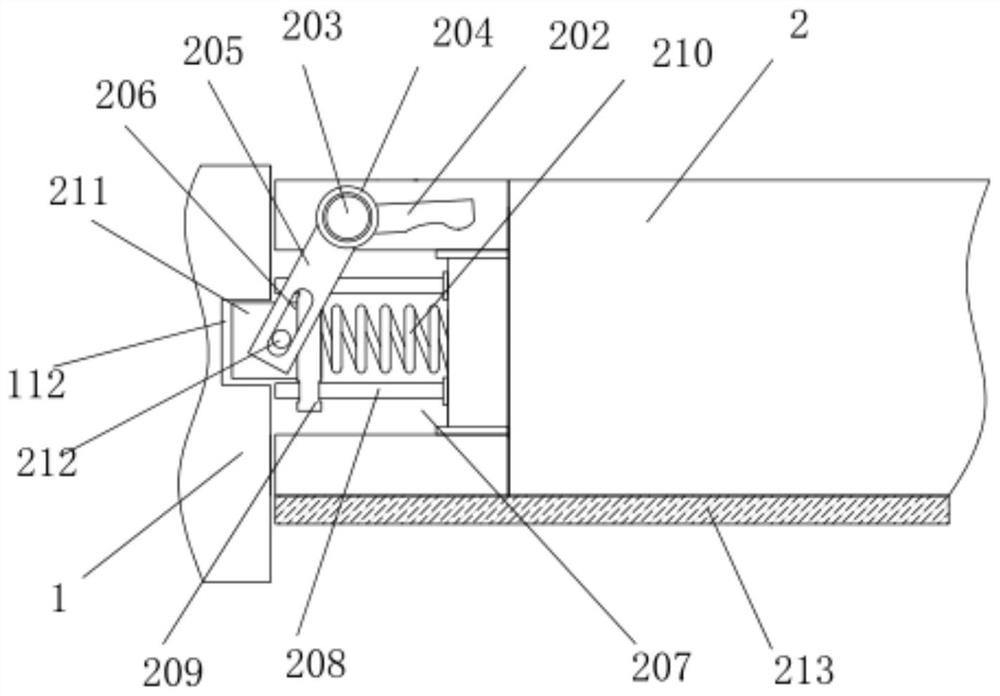

[0038] see image 3 , this embodiment is basically the same as Embodiment 1. Preferably, the top surface of the field effect transistor base 1 is provided with an inner groove 101 for erecting the outer cavity 2 of the field effect transistor, and the inner wall on the left side of the inner groove 101 The middle position of the inner groove 101 is provided with a card slot 112, and the two ends of the inner wall on the right side of the inner groove 101 are provided with a fixing groove 113, and the left end surface of the field effect transistor outer cavity 2 and the inner groove 101 is provided with a concave The hollow groove 207, the upper and lower sides of the hollow groove 207 are horizontally provided with guide rods 208, the guide rod 208 is slidably connected with a guide block 209, and the right end surface of the guide block 209 is provided with a spring 210, so The other end of the spring 210 is in contact with the inner wall of the hollow groove 207, and the le...

Embodiment 3

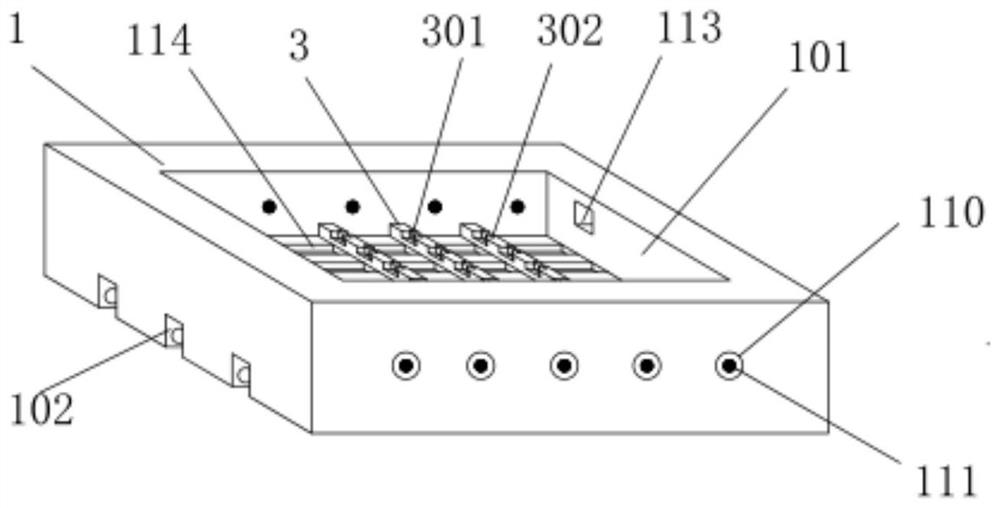

[0042] see figure 2 , this embodiment is basically the same as Embodiment 1. Preferably, the wiring frame 3 includes several wiring boards arranged in the inner groove 101 of the field effect transistor base 1, and the inner bottom surface of the inner groove 101 is provided with Several strip-shaped slots 114, the wiring board is clamped in the strip-shaped slot 114 through the limit block on the bottom surface, and several wiring slots 301 are equidistantly opened on the wiring board, and the wiring slots 301 Positioning holes 302 are opened on both sides of the cable trough 301, and a limit bar 303 is arranged above the cable trough 301. The two ends of the bottom surface of the limit bar 303 are provided with positioning rubber heads 304 that are compatible with the positioning holes 302. The position bar 303 is clamped in the positioning hole 302 by the positioning rubber head 304. The left end of the wiring groove 301 has a trumpet-shaped projected area in the vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com