Grouting stopping method for grouting tail end of steel pipe

A steel pipe and grout stop technology, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve the problems of unstable grouting quality, potential safety hazards, and poor grout sealing effect, so as to avoid potential safety hazards in electricity use and improve Good grouting construction quality and grout sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

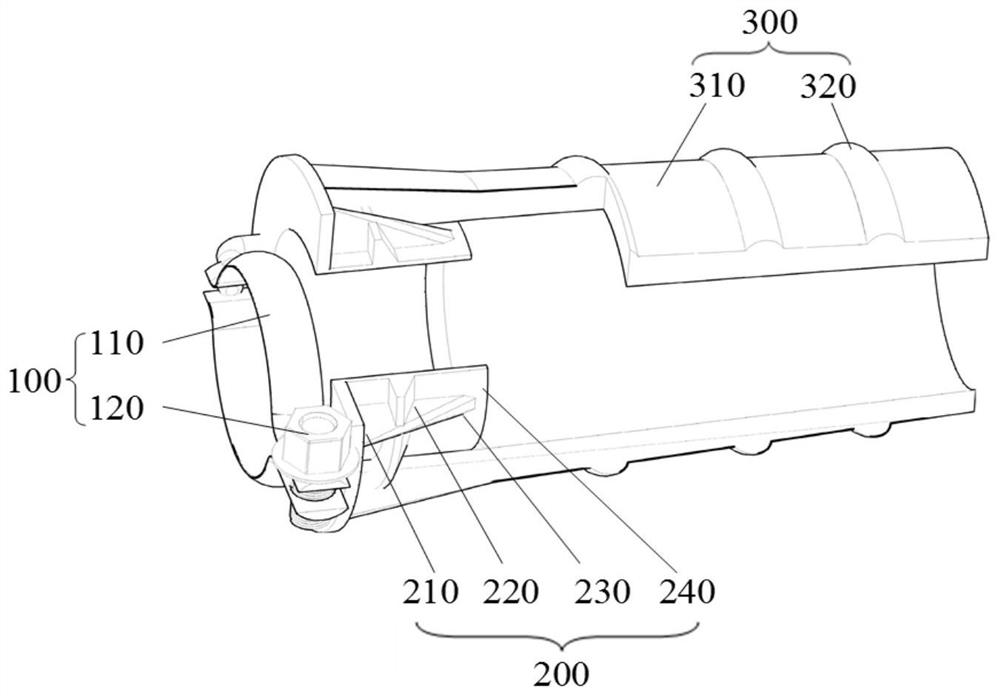

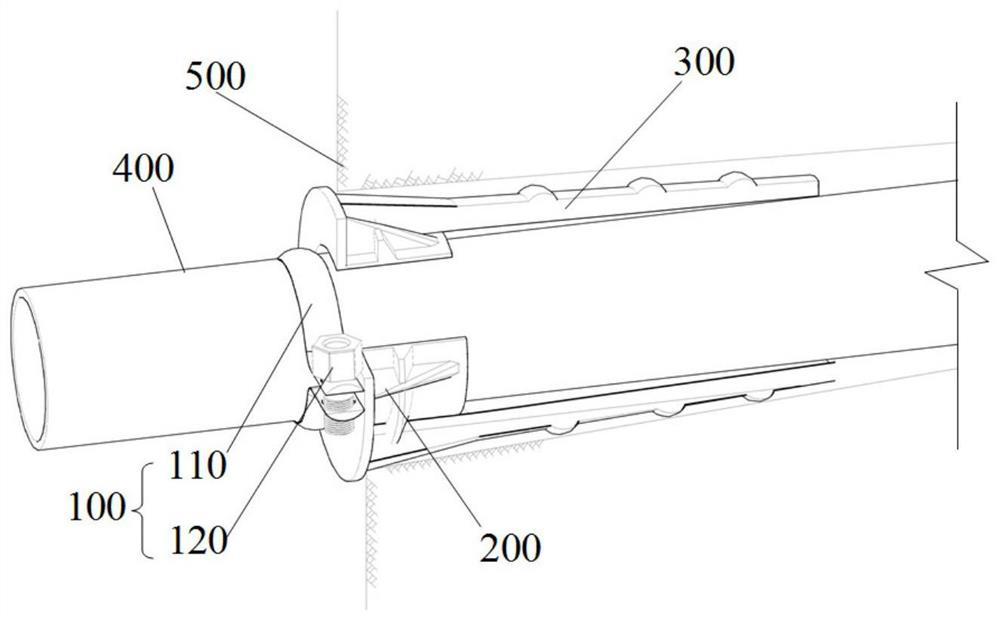

[0079] see Figure 2-Figure 3 , this embodiment proposes a steel pipe grouting hole wall sealing device, including a clamp 100, a positioning steel sleeve 200 and a first sealing rubber sleeve 300, the positioning steel sleeve 200 and the first sealing rubber sleeve 300 The cross section is circular.

[0080] The positioning steel sleeve 200 includes a steel sleeve body 240 and a first positioning ring 210, the first positioning ring 210 is fixedly arranged at one end of the steel sleeve body 240, and the inner diameter of the first positioning ring 210 is exactly It is equal to the outer diameter of the steel sleeve body 240 , and the first positioning ring 210 is just fixed on the end surface of the steel sleeve body 240 .

[0081] The clamp 100 is movably connected to the first positioning ring 210 , and the clamp 100 can rotate relative to the positioning steel sleeve 200 . The clip 100 includes two half-rings 110 and a bolt 120 for forming the two half-rings 110 into a ...

Embodiment 2

[0090] see Figure 4 , this embodiment proposes a grout stop connection device at the tail end of a grouted steel pipe, including a main sleeve 600, the main sleeve 600 includes a second positioning ring 620, a grout outlet pipe 650 and a grout inlet pipe 640, the grout outlet The pipe 650 and the slurry inlet pipe 640 are respectively connected to both sides of the second positioning ring 620, and the slurry outlet pipe 650 and the slurry inlet pipe 640 are connected; The diameter of the slurry pipe 640 is consistent with the inner diameter of the second positioning ring 620 .

[0091] A hexagonal ring 630 is provided at the joint between the slurry feeding pipe 640 and the second positioning ring 620 . In this embodiment, the hexagonal ring 630 is a thickened hexagonal nut.

[0092] The grout inlet pipe 640 is provided with an external thread for connecting with the grout stop valve and grouting equipment.

[0093] The grouting pipe 650 extends into the tail of the grouti...

Embodiment 3

[0102] According to the type of grouting steel pipe that needs to be used under actual working conditions, the steel pipe grouting hole wall sealing device described in Embodiment 1 that is compatible with it can be made in advance, and the embodiment that is suitable for it can be made in advance. The grout stop connection device at the tail end of the grouted steel pipe described in 2.

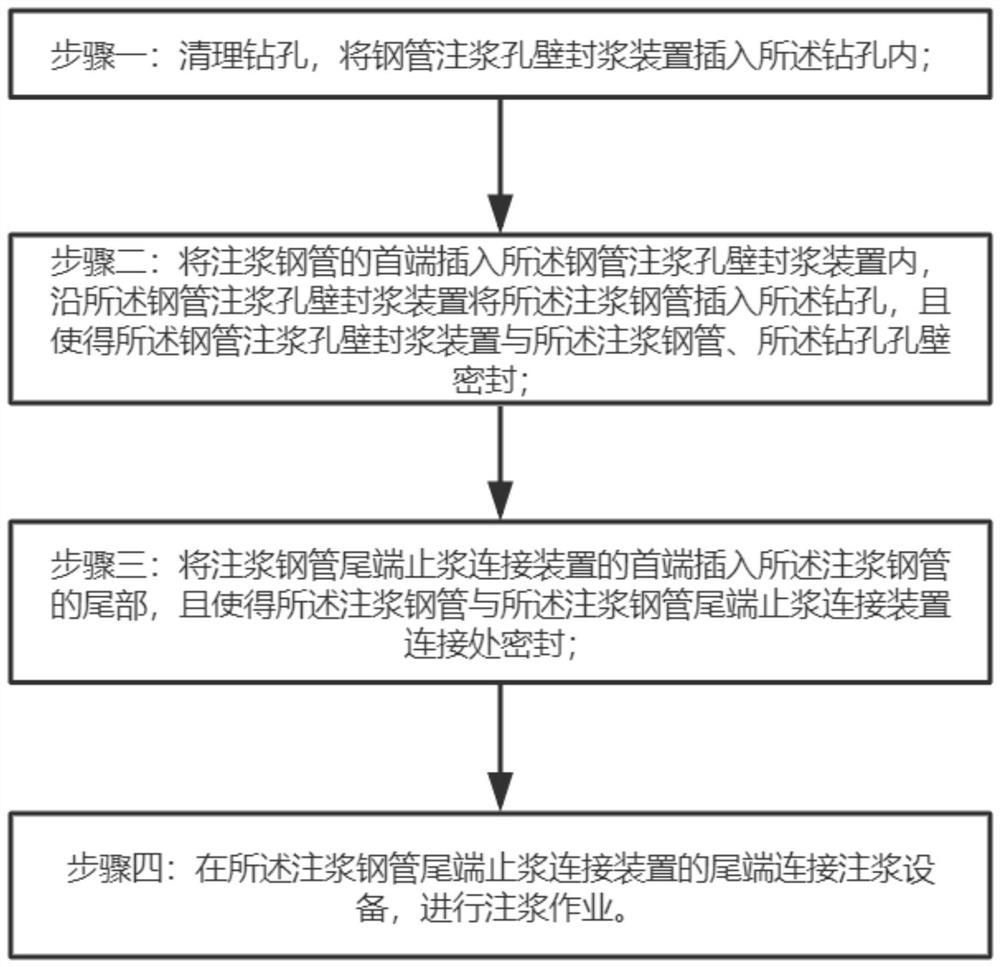

[0103] see Figure 1-Figure 4 This embodiment provides a method for stopping grouting at the end of steel pipe grouting, which requires the use of the grouting device for grouting hole wall of the steel pipe described in Embodiment 1 and the connecting device for stopping the grouting at the end of the grouting steel pipe described in Embodiment 2.

[0104] The method specifically includes the following steps:

[0105] Step 1: Clean up the borehole, insert the steel pipe grouting hole wall grout sealing device into the borehole, specifically, extend the positioning steel sleeve 200 with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com