Flexible drilling and riveting bracket

A riveting bracket and flexible technology, which is applied in the field of aircraft assembly process equipment, can solve the problems of large occupied space, inconvenient use, and slow replacement, and achieve high replacement efficiency, small space occupation, and reduced manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention is described in further detail:

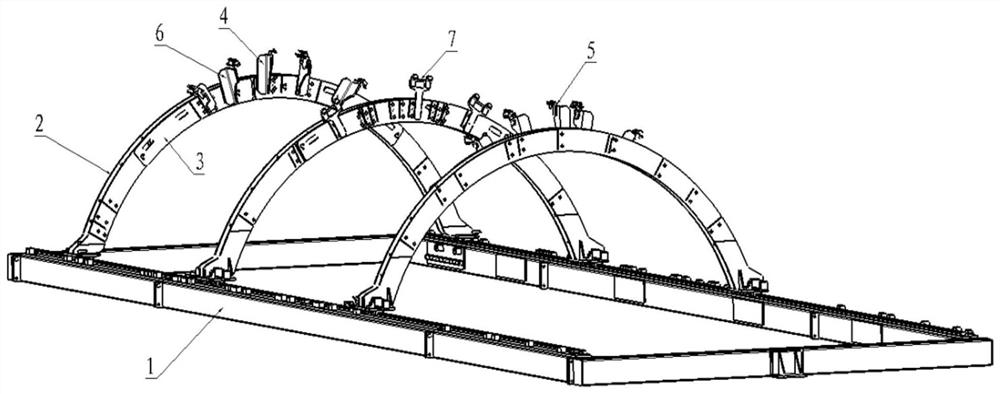

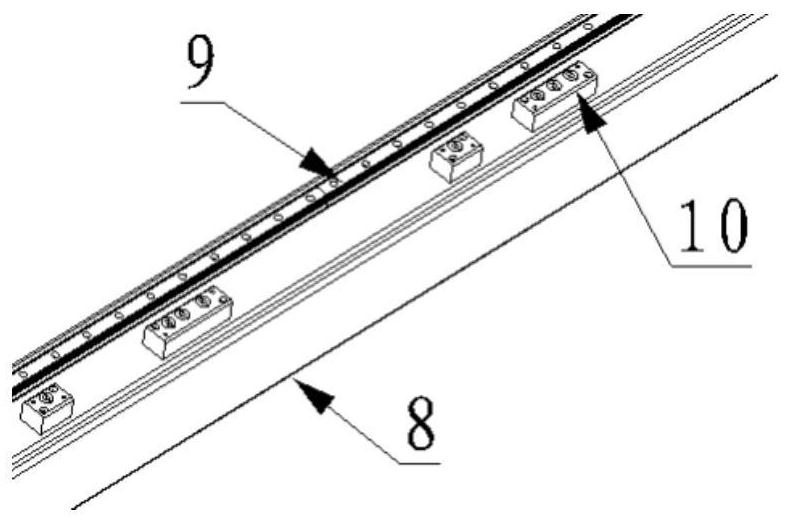

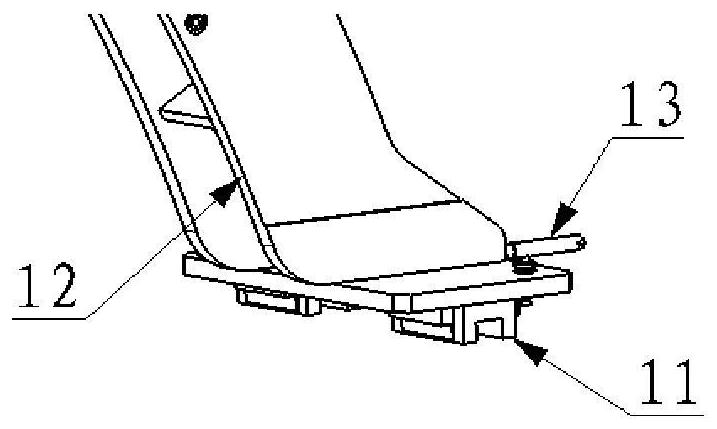

[0027] In order to reduce the occupied space of the drill riveting bracket and adapt to the shapes of various wallboards to the greatest extent, the present invention provides a concretely realized flexible drill riveting bracket, the overall structure of which is as follows figure 1 As shown, the multi-point flexible support includes a frame base 1, a movable gantry beam 2, an adapter plate 3, a round hole skin positioner 4, an oblong hole skin positioner 5, a support clamp 6, and a shape support board assembly7. The movable portal beam 2 is installed on the frame base 1, such as figure 2 As shown, the movable door beam 2 moves linearly along the guide rail 9 on the frame 8 through the combination of the guide rail 9 and the slider 11, and the movable door is controlled by the positioning block 10, the positioning hole on the door beam 12 and the positioning pin 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com