Precise automobile part remanufacturing pretreatment method

An auto parts and remanufacturing technology, which is applied in the field of auto parts manufacturing, can solve the problems of reducing work efficiency, prolonging the cleaning time of the crankshaft, and increasing the maintenance time of the engine crankshaft, so as to increase the maintenance time, prolong the cleaning time, and reduce the work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

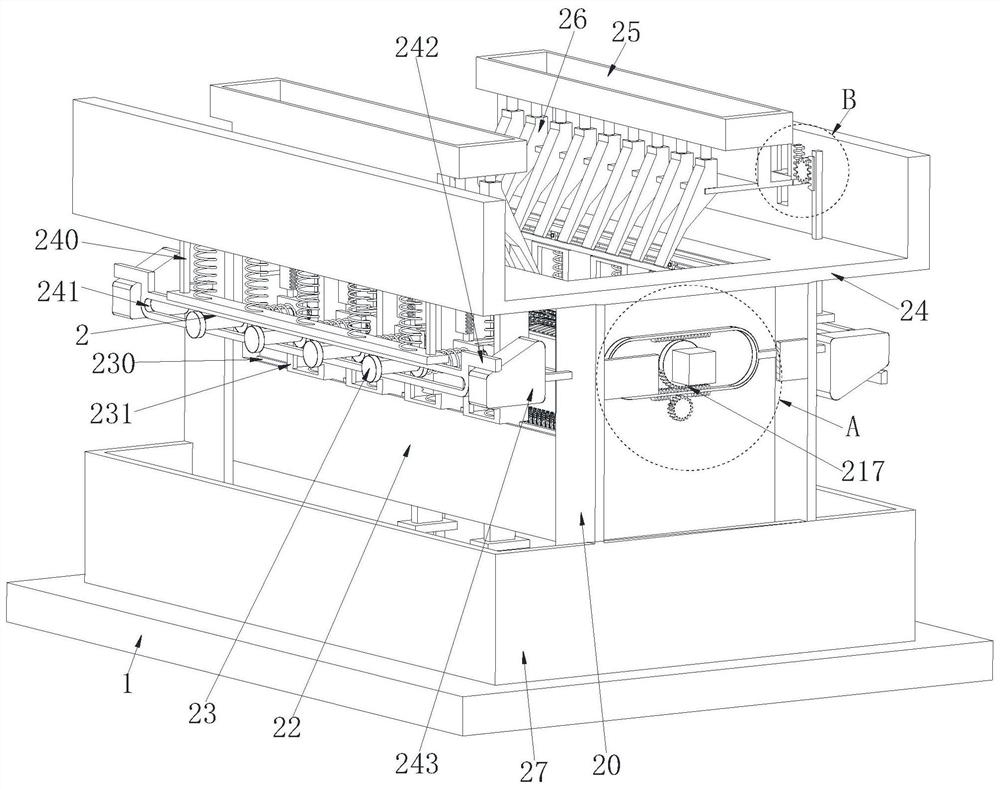

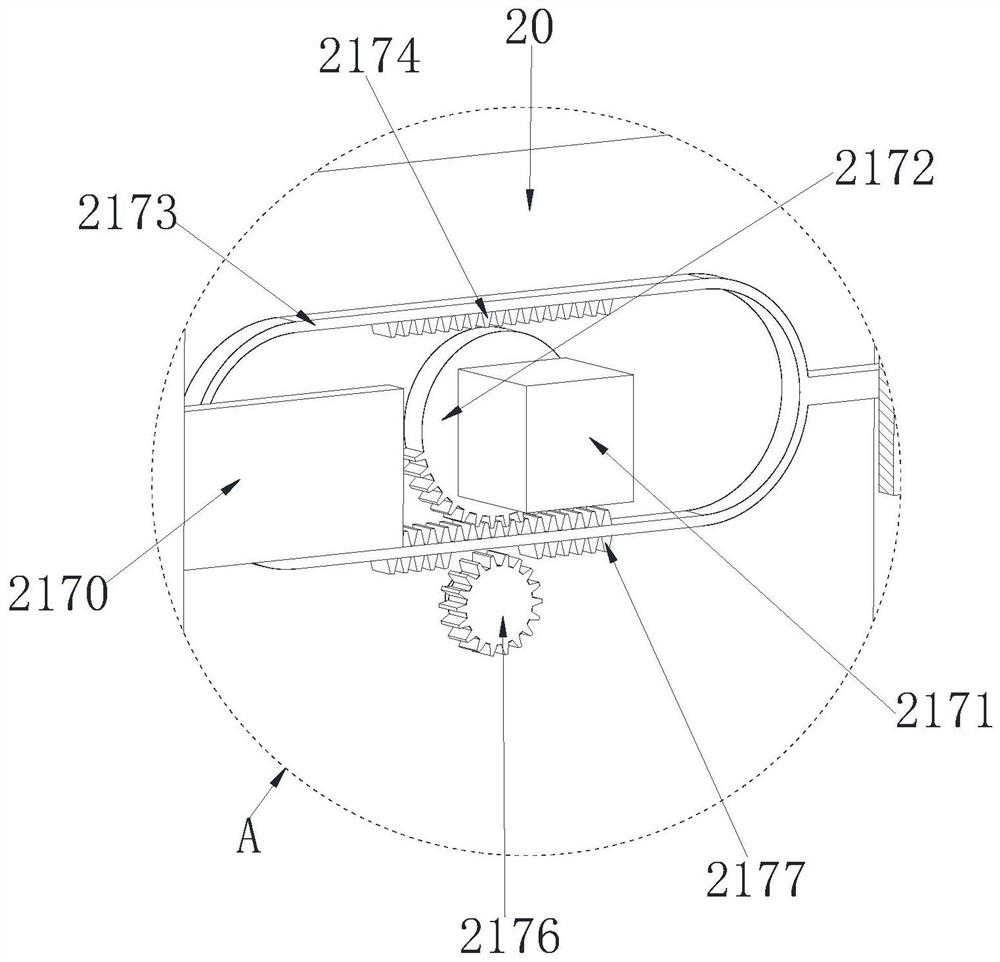

[0033] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 7 , to further elaborate the present invention.

[0034] A precision auto parts remanufacturing pretreatment method, which uses a precision auto parts remanufacturing pretreatment equipment, the precision auto parts remanufacturing pretreatment equipment includes a base 1 and a cleaning device 2, using the above precision auto parts The specific method of cleaning the engine crankshaft of precision auto parts by the component remanufacturing pretreatment equipment is as follows:

[0035] Step 1. Preparatory work: debug the precision auto parts remanufacturing pretreatment equipment, and disassemble the engine crankshaft that needs to be cleaned;

[0036] Step 2. Cleaning of the engine crankshaft: place and install the engine crankshaft disassembled in step 1 on the clamping unit 21, and then start...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com