An integrated missile launching cable assembly and its preparation method

A missile launching and cable assembly technology, which is applied in the direction of cable/conductor manufacturing, line/collector components, cables, etc., can solve the problems of increasing the probability of missile launch failure and the weight of the whole machine, and achieve light weight, small size, The effect of long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

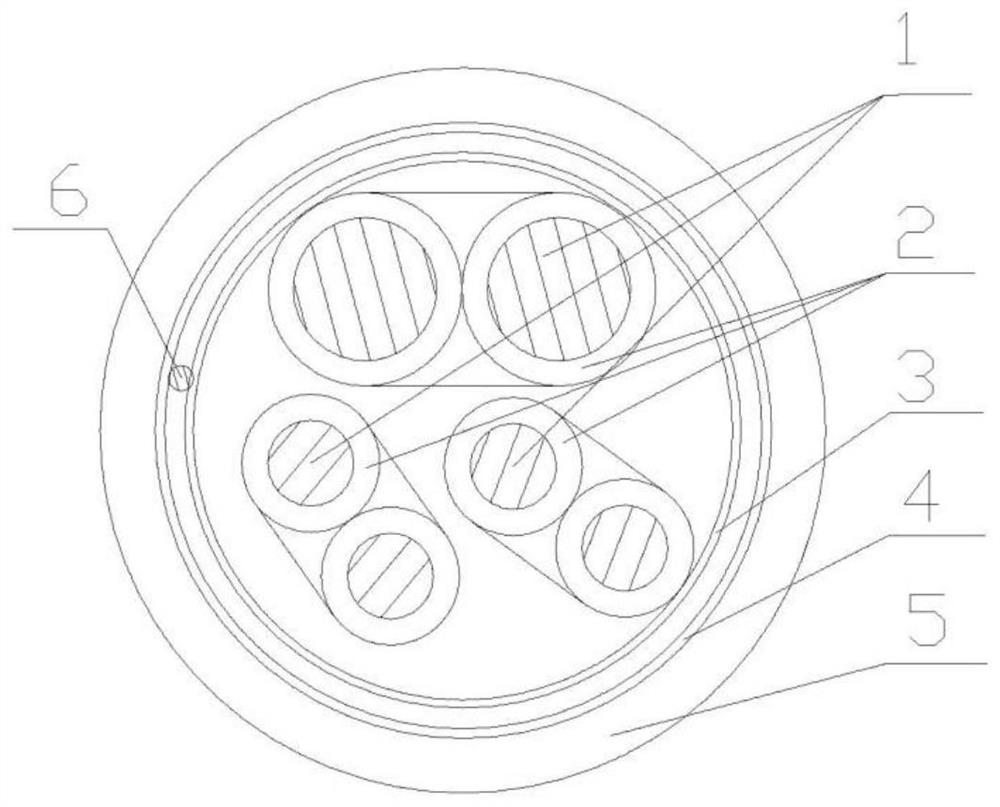

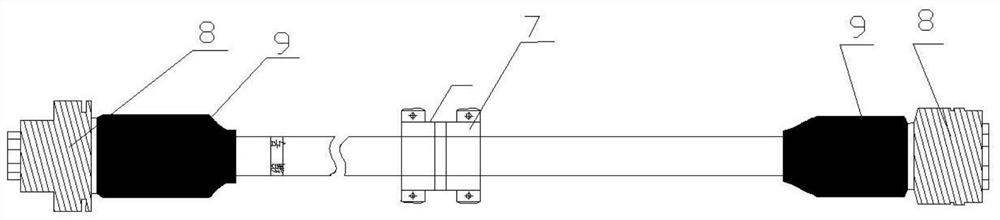

[0034] An integrated missile launch cable assembly incorporating figure 1 , figure 2 Instructions, including:

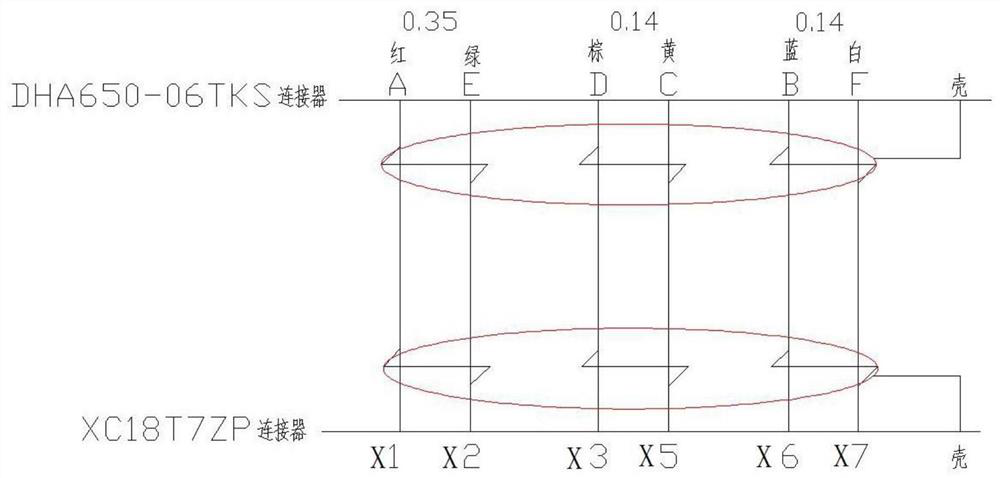

[0035] The integrated cable includes a wire assembly, an isolation layer 4 arranged on the surface of the wire assembly, and a sheath 5 arranged on the surface of the isolation layer. A longitudinal drain wire 6 is arranged between the isolation layer 4 and the surface of the wire assembly; the wire assembly includes wires and Shield 3;

[0036] Connectors 9 are arranged at both ends of the integrated cable, and the connectors 9 have ports for connecting wires respectively;

[0037] The tail cover 8 is arranged at one end of the connector 9 to connect the shielding layer 3 and the longitudinal drain wire 6, for protecting the connector and the integrated cable;

[0038] The buckle 7 is arranged on the integrated cable close to the connector 9, and is used to cut off the integrated cable instantly when the missile is launched. The buckle is preferably a chrome-pl...

Embodiment 2

[0045] A method for preparing the above-mentioned integrated missile launching cable assembly, comprising the following steps:

[0046] S1. Preparation of wires: Use silver-plated copper wires with a silver layer thickness of 0.011mm to twist to obtain conductors for ignition wires, set wires, and RS485 communication wires, and wrap polytetrafluoroethylene film on the surface of the conductors to form an insulating layer to obtain the thickness of the insulating layer Conductors not less than 0.15mm;

[0047] S2. Preparation of wire components: Twisting each of the two ignition wires, setting wires and RS485 communication wires respectively, twisting the three pairs of twisted wires in a certain order, and wrapping them with aluminum-plastic composite tape to form the shielding layer , to get the wire assembly;

[0048] S3. Preparation of integrated cables: Attach longitudinal drainage wires on the surface of the wire assembly, wrap a layer of high-temperature resistant polyimi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com