Multi-information fusion fault diagnosis method and system for thrust vectoring nozzle control system

A technology of multi-information fusion and control system, applied in the field of multi-information fusion fault diagnosis of vector nozzle control system, can solve problems such as low accuracy, improve accuracy, reduce feature dimension, reduce missed detection rate and false detection rate. The effect of the alarm rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

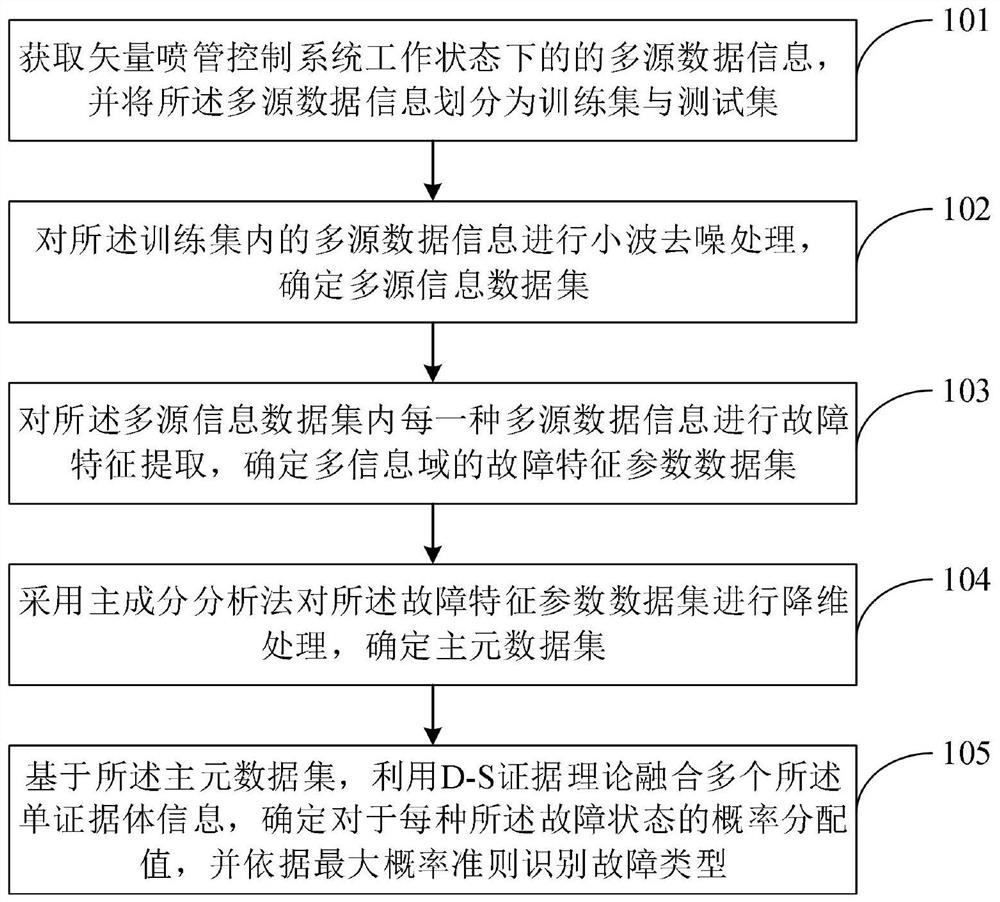

[0072] Based on the multi-information fusion fault diagnosis method of the vector nozzle control system provided by the present invention, as an optional embodiment of the present invention, the flow of the multi-information fusion fault diagnosis method based on D-S evidence theory is as follows:

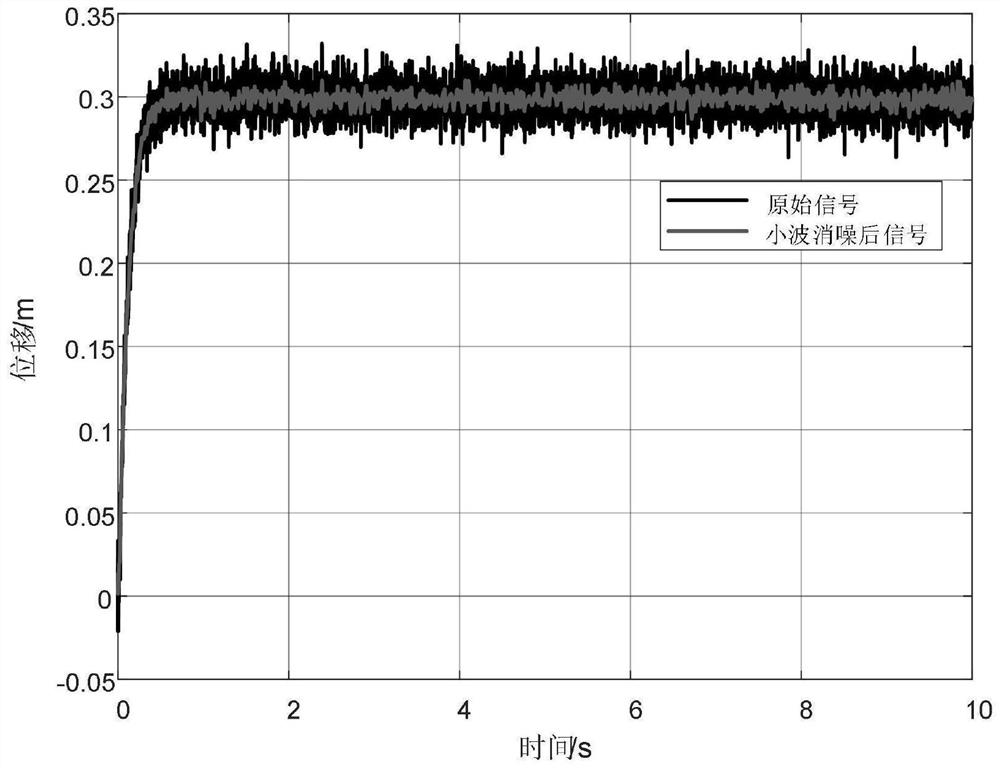

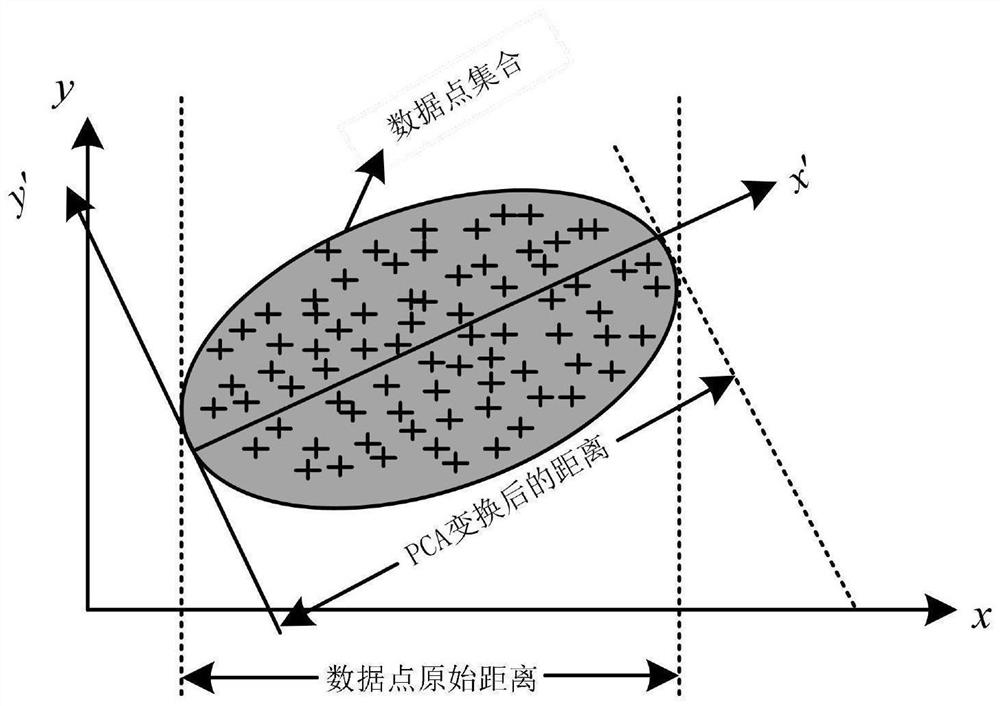

[0073] Step 1: Obtain multi-source data information of the vector nozzle control system. Vector Nozzle A 91 The four failure modes of the actuating circuit are the diagnostic framework, that is, θ={F 1 , F 2 , F 3 , F 4}, representing system normality, servo valve wear, actuator wear and LVDT sensor drift, respectively. When a circuit of the vector nozzle device fails, it will affect the change of its own sensor signal, and at the same time, it will also affect the sensor signal in its coupling circuit, making other circuits appear certain fault characteristics. Therefore, the sensor signals with higher sensitivity to the fault state in the three loops of the vector nozzle con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com