A kind of silicon carbide nanometer heat-insulating wave-absorbing composite material and preparation method thereof

A technology of silicon carbide nanowires and nano heat insulation, which is applied in the fields of carbon compounds, chemical instruments and methods, carbon preparation/purification, etc., can solve the problem of not having the advantages of three-dimensional space network structure, and it is difficult to effectively balance heat insulation and wave absorption performance , failure to achieve expected goals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

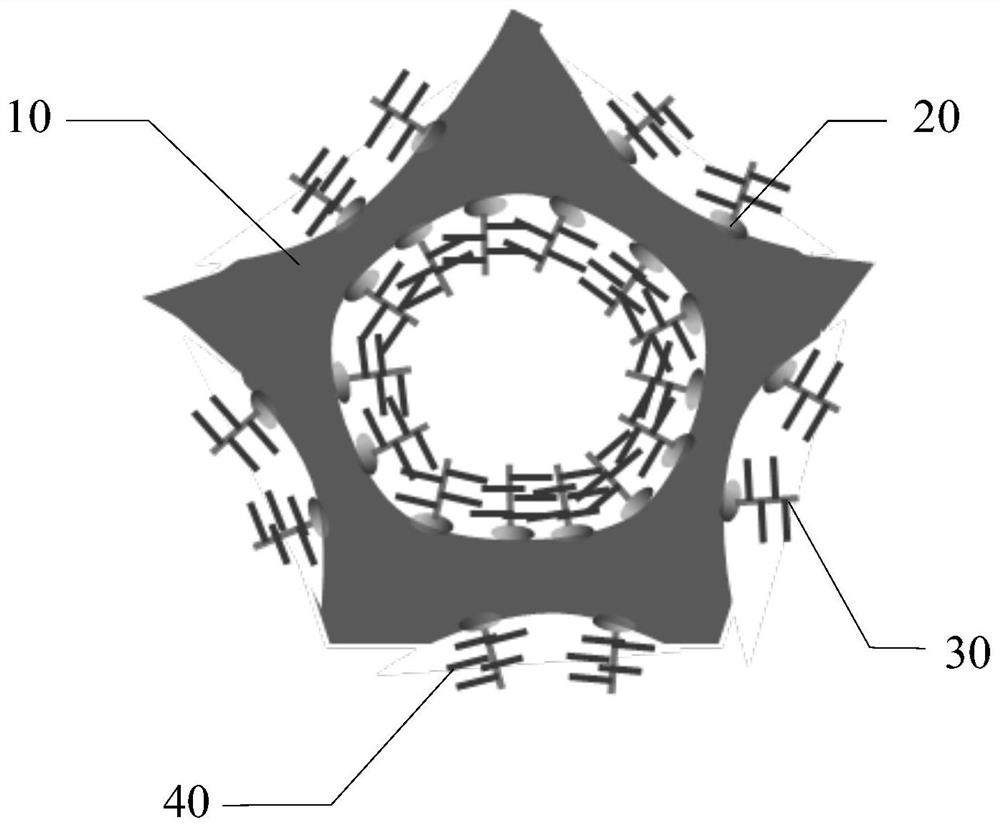

[0024] refer to figure 1 , is a schematic diagram of the structure of a silicon carbide nano-heat-insulating wave-absorbing composite material, 10 is a carbon foam substrate template, 20 is a silicon carbide coating enhanced interface, 30 is an initial silicon carbide nanowire, 40 is a secondary silicon carbide nanowire, volume Density is 20.0kg / m 3 , the thermal conductivity at room temperature is 0.032W / (m·K), the minimum reflection loss is -38.0dB, the carbon foam substrate template is a three-dimensional open-cell structure, the compressive modulus is 250.0kPa, and the absorption capacity is 7.8kJ / m 3 , the porosity is 96.0%, and the cell size is 30.0 μm; the reinforced interface of the silicon carbide coating is discontinuous and discontinuous on the surface of the carbon foam substrate skeleton, with a thickness of 1.5 μm, a compressive strength of 1.2 MPa, and a compressive modulus of 12.0 MPa. ; The SiC nanowire network structure grows in dendritic bifurcation at the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com