High-temperature-resistant and wear-resistant gear and preparation method thereof

A high-temperature-resistant, gear-based technology, applied in the field of high-temperature-resistant and wear-resistant gears and its preparation, can solve the problems of reduced wear resistance, low production efficiency, and short service life of gears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

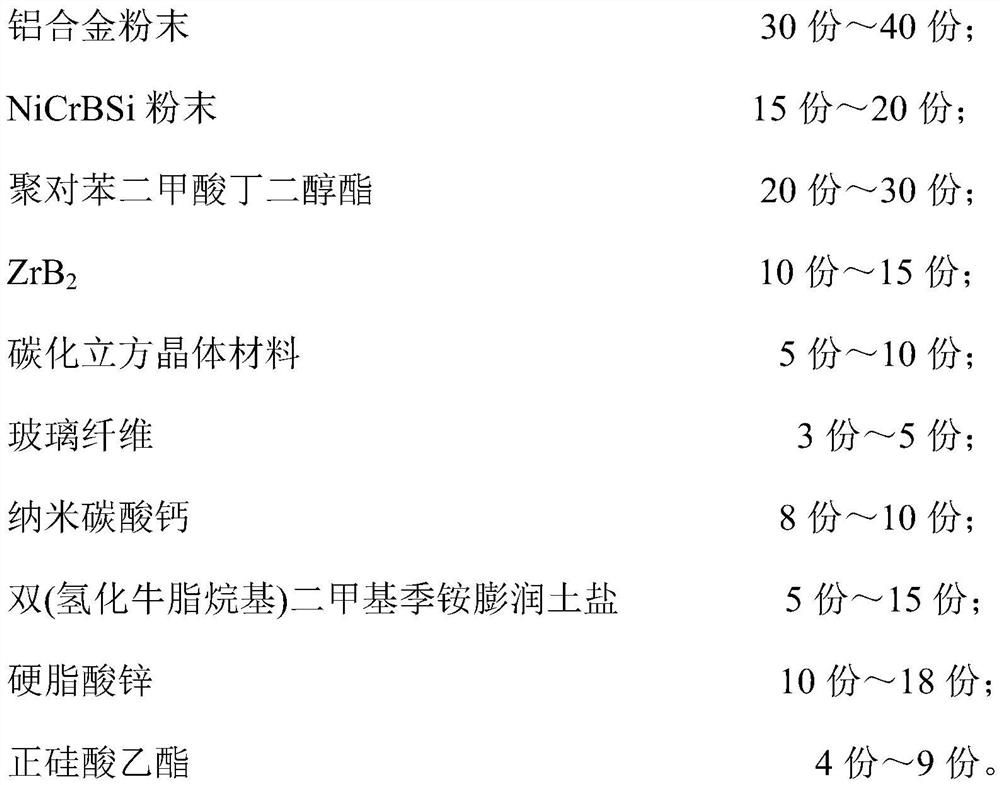

[0032] A high-temperature-resistant and wear-resistant gear provided in this embodiment, the material for preparing the high-temperature-resistant and wear-resistant gear includes the following components in parts by weight:

[0033]

[0034] This embodiment also provides a method for preparing the above-mentioned high-temperature-resistant and wear-resistant gear, including the following steps:

[0035] 1) 30 parts of 6061 aluminum alloy powder, 15 parts of NiCrBSi powder, 10 parts of ZrB 2 , 5 copies of B 4 C is placed in a planetary ball mill and ground at room temperature for 1.5h at a speed of 200rpm to form a nanometer particle size metal mixed powder with a particle size of 5nm;

[0036] 2) Dissolve 8 parts of nano-calcium carbonate with a particle size of 20nm and 4 parts of tetraethyl orthosilicate in a mixed solution of ethanol and distilled water, and stir at a temperature of 55° C. at a speed of 150 rpm for 30 minutes to obtain a modified compound with a hydrox...

Embodiment 2

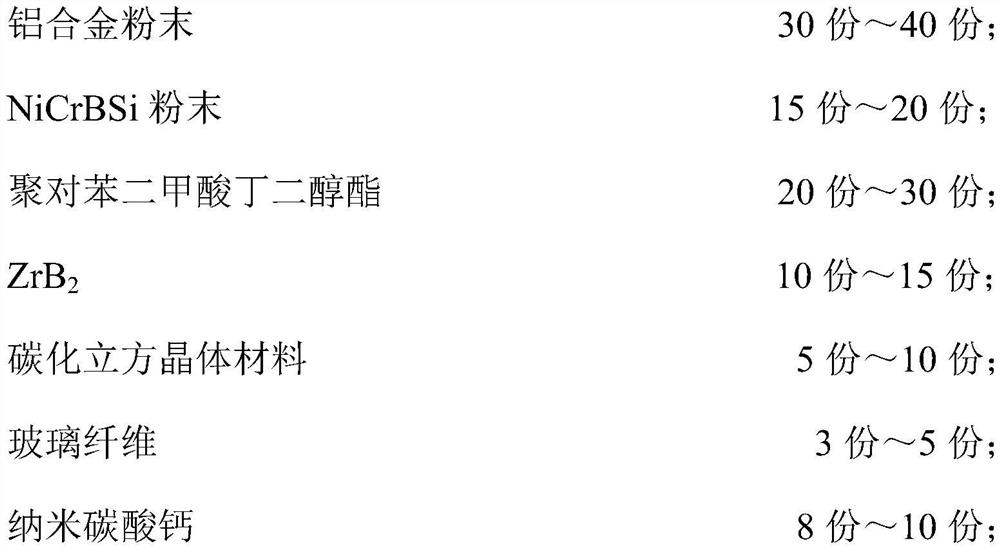

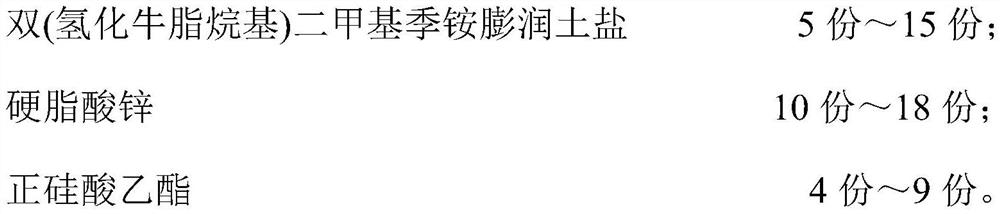

[0041] A high-temperature-resistant and wear-resistant gear provided in this embodiment, the material for preparing the high-temperature-resistant and wear-resistant gear includes the following components in parts by weight:

[0042]

[0043] This embodiment also provides a method for preparing the above-mentioned high-temperature-resistant and wear-resistant gear, including the following steps:

[0044] 1) 35 parts of 6205 aluminum alloy powder, 17.5 parts of NiCrBSi powder, 12.5 parts of ZrB 2 , 3.5 parts of TiC and 4 parts of ZrC are placed in a planetary ball mill, and ground at room temperature for 1.75 hours at a speed of 250 rpm to form a nano-sized metal mixed powder with a particle size of 10 nm;

[0045] 2) 9 parts of nano-calcium carbonate with a particle size of 35nm and 6.5 parts of tetraethyl orthosilicate were dissolved in a mixed solution of ethanol and distilled water, and stirred at 170 rpm for 40 min at a temperature of 58 ° C to obtain a compound with a ...

Embodiment 3

[0050] A high-temperature-resistant and wear-resistant gear provided in this embodiment, the material for preparing the high-temperature-resistant and wear-resistant gear includes the following components in parts by weight:

[0051]

[0052]

[0053] This embodiment also provides a method for preparing the above-mentioned high-temperature-resistant and wear-resistant gear, including the following steps:

[0054] 1) 40 parts of 6463 aluminum alloy powder, 20 parts of NiCrBSi powder, 15 parts of ZrB 2 10 parts of SiC are placed in a planetary ball mill and ground at room temperature for 2 hours at a speed of 300rpm to form a nano-sized metal mixed powder with a particle size of 15nm;

[0055] 2) Dissolve 10 parts of nano-calcium carbonate with a particle size of 50 nm and 9 parts of tetraethyl orthosilicate in a mixed solution of ethanol and distilled water, and stir at 190 rpm for 45 minutes at a temperature of 60° C. to obtain a modified compound with hydroxyl functiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com