Bentonite coagulant and application thereof in wastewater treatment

A technology of wastewater treatment and bentonite, which is applied in the fields of animal husbandry wastewater treatment, flocculation/sedimentation water/sewage treatment, waste coating treatment, etc. It can solve the problems of small dispersion and loose flocs, unfavorable centralized disposal, easy diffusion, etc., and achieve floating performance. Good, low production cost, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

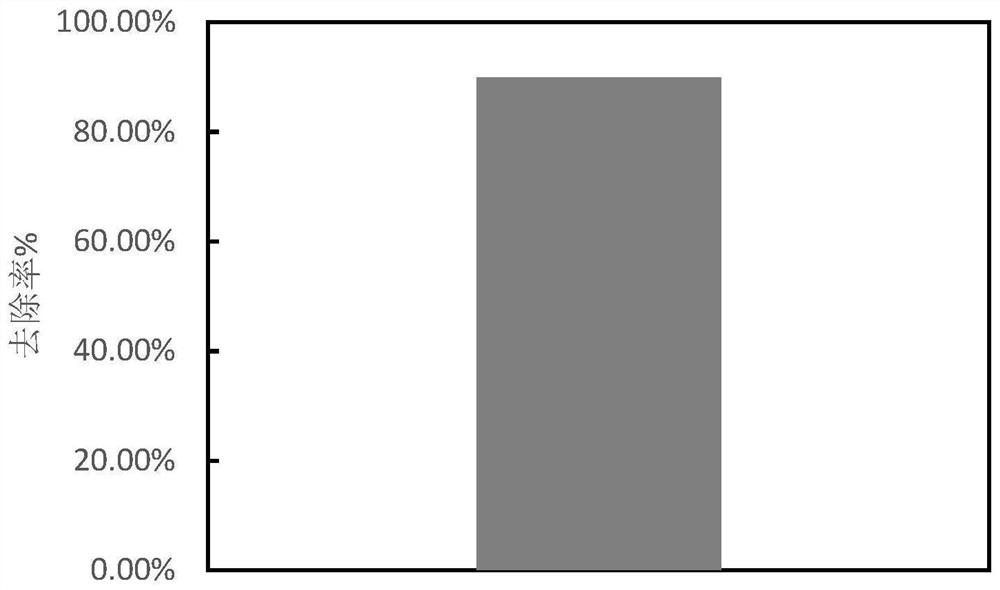

[0052] This embodiment provides the application of bentonite coagulant in the purification of water-based paint wastewater, for water-based paint stock solution wastewater with COD greater than hundreds of thousands: the specific steps include:

[0053] 1) First take 0.4mL of water-based paint stock solution, add 200mL of deionized water to obtain a water-based paint aqueous solution; add 0.005g of polyaluminum chloride to the above-mentioned water-based paint aqueous solution, and stir at a speed of 700rpm for 2min;

[0054] 2) Continue to add 1g of bentonite and stir for 2min at a speed of 700rpm;

[0055] 3) Continue to add 1 ml of polyacrylamide aqueous solution with a mass fraction of 0.6%, stir at a speed of 700 rpm for 1 min, and then stir at a speed of 500 rpm for 1 min;

[0056] 4) Settling for 10 minutes to obtain a clear solution.

[0057] Add bentonite coagulant to treat water-based paint wastewater according to the above method, and measure its turbidity and COD....

Embodiment 2

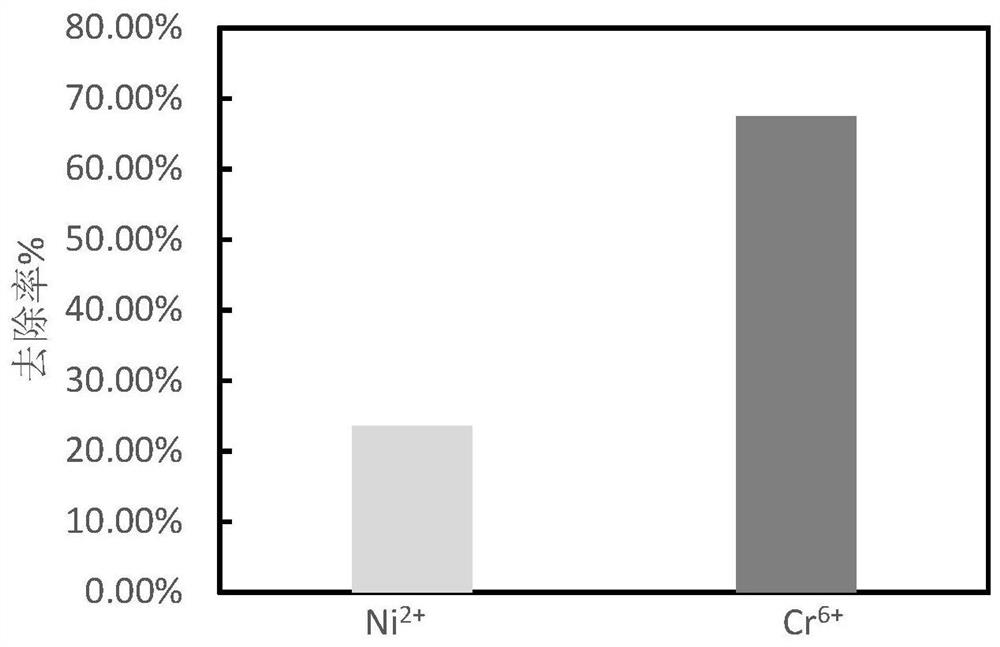

[0064] This embodiment provides the application of accumulated bentonite coagulant in the purification of heavy metal wastewater. For wastewater containing chromium and nickel, the specific steps include:

[0065] 1) prepare respectively the Cr of 20mg / L 6+ and 50mg / L Ni 6+ For waste water, take 200mL waste water, add 0.005g polyaluminum chloride respectively, and stir at 700rpm for 2min;

[0066] Step S2, continue to add 0.2 g of bentonite respectively, and stir at a speed of 700 rpm for 2 min;

[0067] Step S3, continue to add 1 ml of polyacrylamide aqueous solution with a mass fraction of 0.6%, stir at 700 rpm for 30 min, and then at 500 rpm for 30 min;

[0068] Step S4, settling for 10 minutes to obtain two clear liquids.

[0069] Get the above two clear liquids, filter them with a 0.45 μm filter head through a syringe, and measure the concentrations of hexavalent chromium and nickel ions in the clear liquids by flame atomic absorption spectrophotometry to obtain the fo...

Embodiment 3

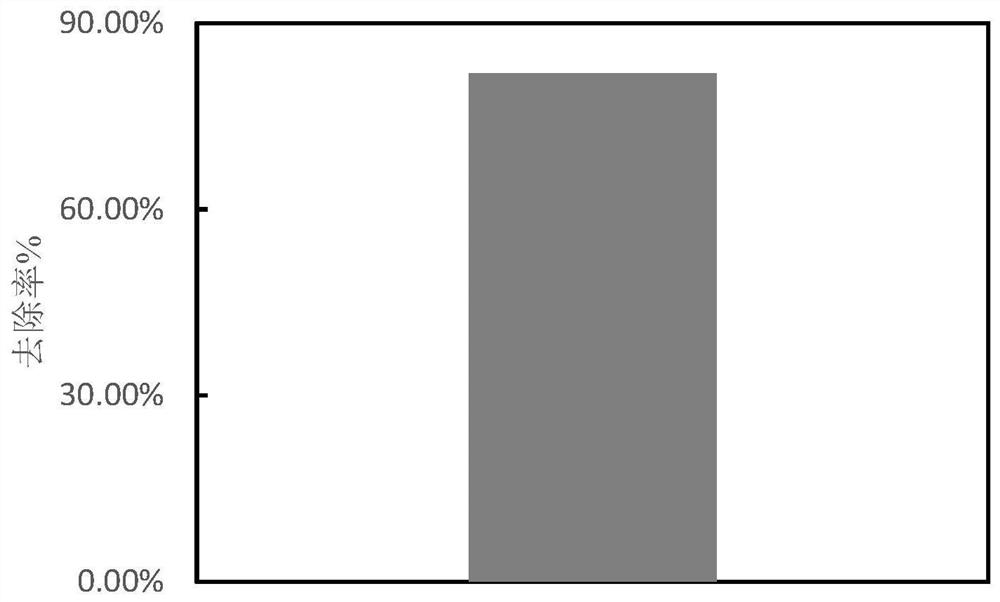

[0072] This embodiment provides the application of accumulated bentonite coagulant in the purification of waste water containing organic pollutants. Bisphenol A is selected as the target pollutant. The specific steps include:

[0073] 1) To prepare 5 mg / L bisphenol A contaminated wastewater, take 200 mL of bisphenol A contaminated wastewater; add 0.005 g of polyaluminum chloride to the above 200 mL of bisphenol A contaminated wastewater, and stir for 2 minutes;

[0074] 2) Continue to add 1.0g of bentonite and stir for 2 minutes;

[0075] 3) Continue to add 1 ml of polyacrylamide aqueous solution with a mass fraction of 0.6%, first stir at 700 rpm for 30 min, and then at 500 rpm for another 1 h;

[0076] Step S4, settling for 10 minutes to obtain a clear liquid.

[0077] Take the upper clear liquid and filter it through a syringe with a 0.45 μm filter head, scan the bisphenol A solution in the range of 100-800 nm with a UV spectrophotometer, and measure the maximum absorption...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com