A color masterbatch mixing device and a plastic bottle injection molding process

A technology of mixing device and material mixing device, which is applied in the field of injection molding of plastic products, can solve the problems of reduced color mixing degree and poor product color uniformity, and achieve the effects of improving color uniformity, increasing confusion, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The application will be described in further detail below in conjunction with the accompanying drawings.

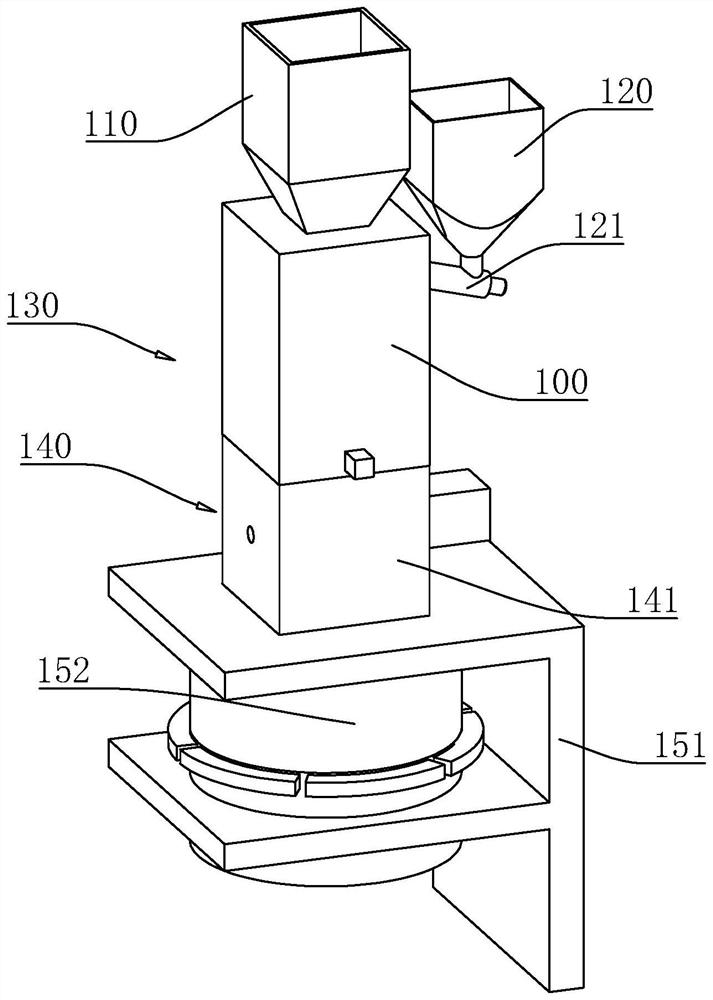

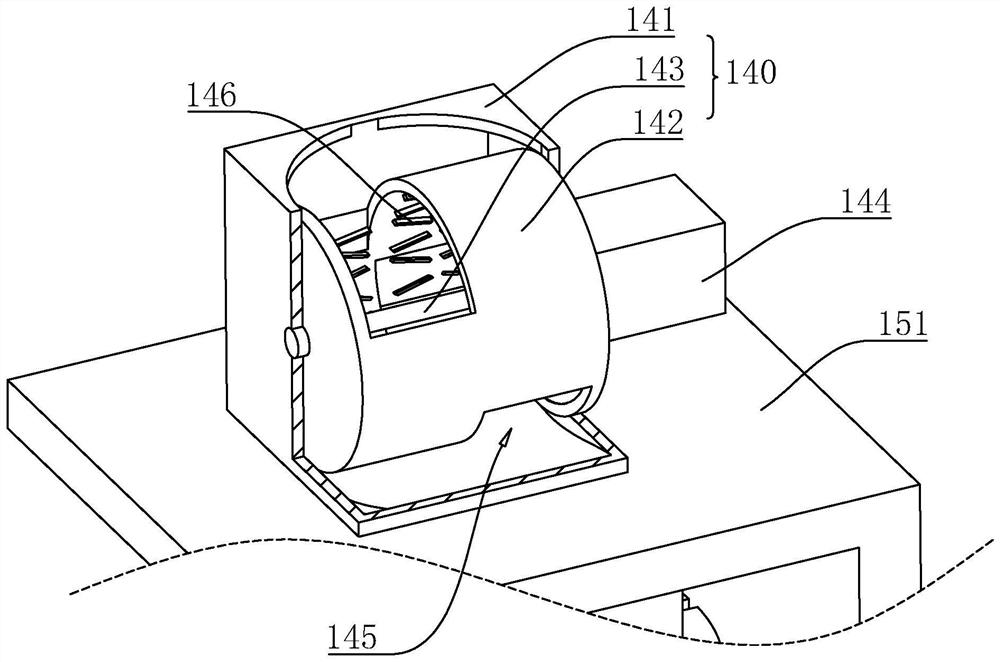

[0041] The embodiment of the present application discloses a masterbatch mixing device, refer to figure 1 , including a mixing box 100, the mixing box 100 is connected with a main hopper 110 and a masterbatch hopper 120, the main hopper 110 is connected to the top of the mixing box 100, a screw conveyor 121 is installed on the side of the mixing box 100, and the color masterbatch hopper 120 is installed on the screw conveyor On machine 121. There is a bulk material structure 130 inside the mixing box 100, and a mixing device 140 is connected to the discharge end of the mixing box 100 at the same time. , the mixing effect is better.

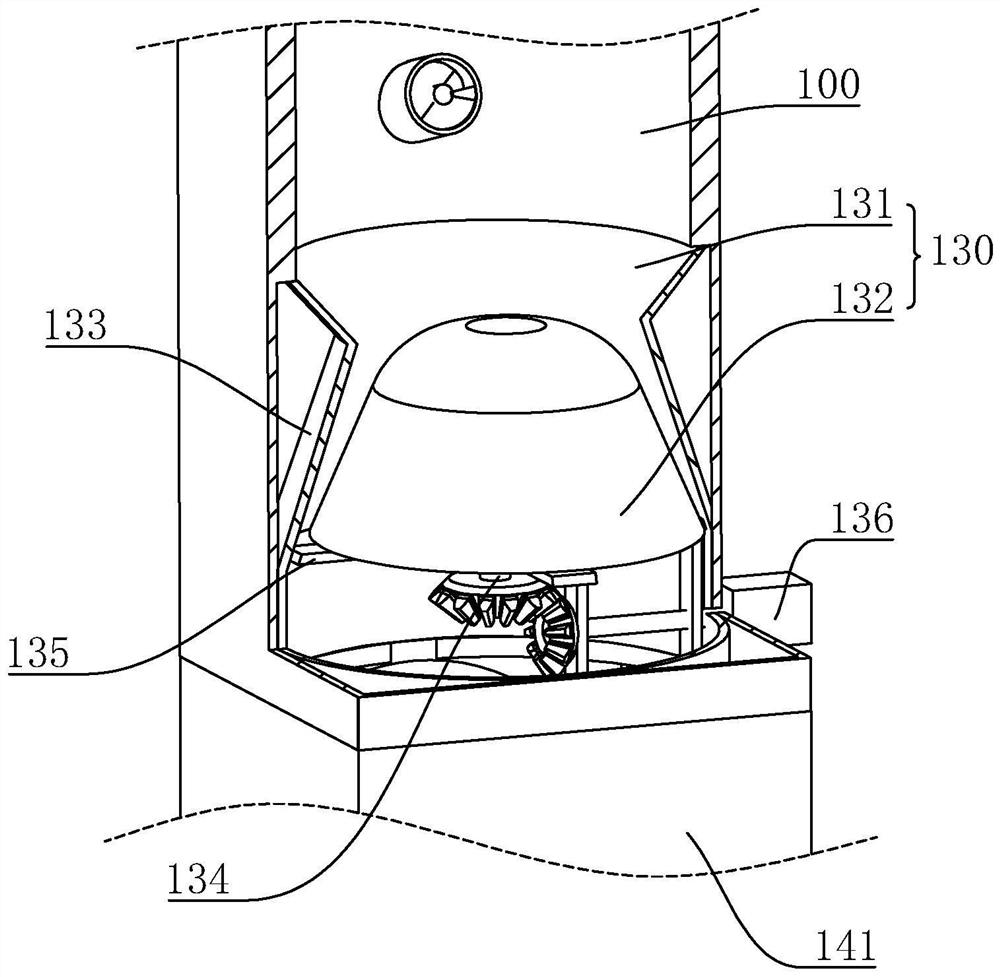

[0042] refer to figure 1 , figure 2 The bulk material structure 130 includes a funnel-shaped bulk material hopper 131 arranged in the mixing box 100 , and a distributing head 132 eccentrically connected to the outlet of the bulk mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com