Valve pressing plate wiring device and diesel engine valve control device

A wiring device and valve technology, applied in the direction of engine control, connection, electrical components, etc., can solve the problems of easy tearing of insulating sleeves, easy short circuit, easy rotation of wiring studs, etc., so as to achieve not easy to tear, avoid short circuit, reduce The effect of the short-circuit fault on the probability of occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

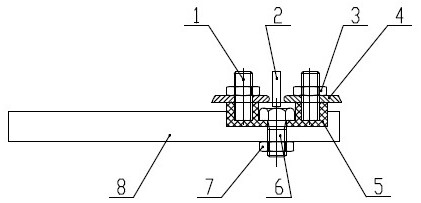

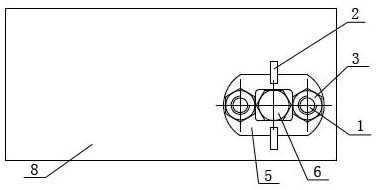

[0024] The embodiment of the present invention provides a valve pressure plate wiring device, such as figure 1 As shown, it includes a wiring assembly and an insulator 5, and the insulator 5 is fixedly connected to the valve pressure plate 8. The wiring assembly includes: a terminal stud 1 and a compression nut 3; one end of the terminal stud 1 is pre-embedded in the insulator 5, so that the terminal stud 1 is fixed in the insulator 5; the other end of the terminal stud 1 is provided with a wire clamp Ring 4, the compression nut 3 is threadedly connected with the terminal stud 1, and is used to compress the wire pressure ring 4, the body of the wire pressure ring 4 is connected with a wire, and the other end of the wire is connected to the positive and negative poles of the two-way electromagnet, thereby Realize leading out the positive and negative wires of the two-way electromagnet in the valve automatic control device.

[0025] One end of the terminal stud 1 provided by th...

Embodiment 2

[0030] The embodiment of the present invention also provides a valve control device for a diesel engine, including a valve pressure plate 8 and a valve pressure plate wiring device, specifically:

[0031] Such as figure 1 As shown, it includes a wiring assembly and an insulator 5, and the insulator 5 is fixedly connected to the valve pressure plate 8. The wiring assembly includes: a terminal stud 1 and a compression nut 3; one end of the terminal stud 1 is pre-embedded in the insulator 5, so that the terminal stud 1 is fixed in the insulator 5; the other end of the terminal stud 1 is provided with a wire clamp Ring 4, the compression nut 3 is threadedly connected with the terminal stud 1, and is used to compress the wire pressure ring 4, the body of the wire pressure ring 4 is connected with a wire, and the other end of the wire is connected to the positive and negative poles of the two-way electromagnet, thereby Realize leading out the positive and negative wires of the two-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com