Flat elliptic cavity blank body containing valve body and valve cover suitable for multi-valve-type valve and forming method

A molding method and green body technology, applied in the direction of valve device, valve details, valve shell structure, etc., can solve the problems of poor casting compactness and quality, molds that cannot be used universally, and molds that are not universally used, so as to achieve good streamlines and processing performance. Low energy consumption and human resource consumption, good environmental protection and compact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

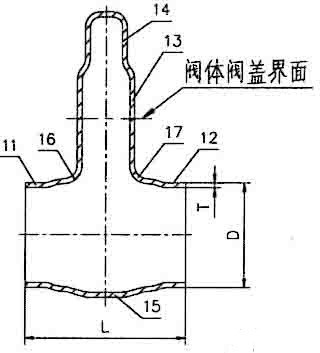

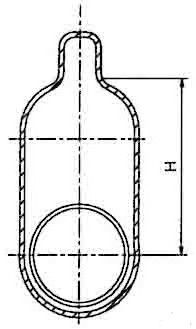

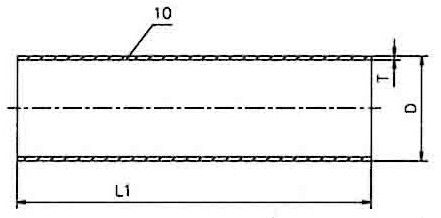

[0048]A green body (hereinafter referred to as green body) suitable for multi-valve flat elliptical cavity containing valve body and bonnet (hereinafter referred to as green body) and a general hydraulic forming processing method. The blank is designed according to the requirements of being suitable for different pressures and valves, facilitating forming, and high versatility. The body shape, the left end 11 and the right end 12 of the green body have a cylindrical section with the same diameter, the diameter D of the cylindrical section is the same as the outer diameter D of the seamless steel tube blank (hereinafter referred to as the tube blank), and the flat oval middle section of the blank body 13 The long axis is large in size and can accommodate the movement of larger opening and closing parts in various valves. The upper height H of the middle section 13 can be processed at different heights depending on the valve. There is a small cylindrical section 14 on the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com