Anti-loosening nut

An anti-loosening and nut technology, applied in the direction of nuts, screws, bolts, etc., can solve the problems of traditional structure loosening danger and can not fully meet the needs of special industries, and achieve the effect of simple structure, reasonable design and good anti-loosening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

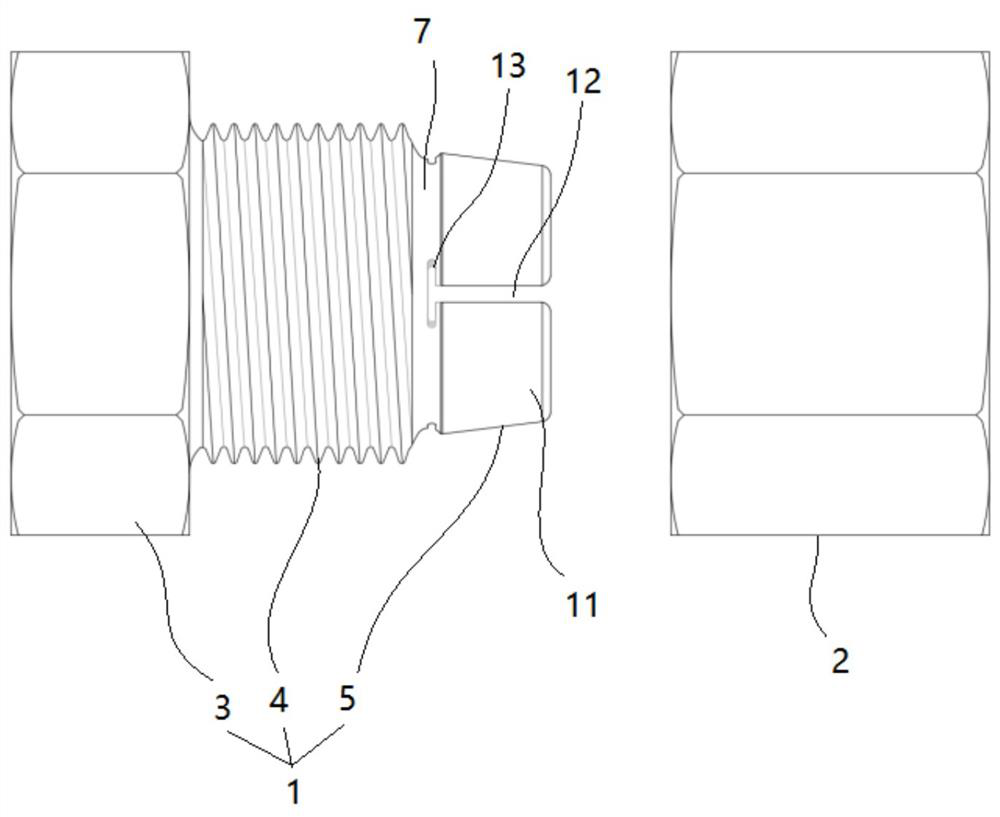

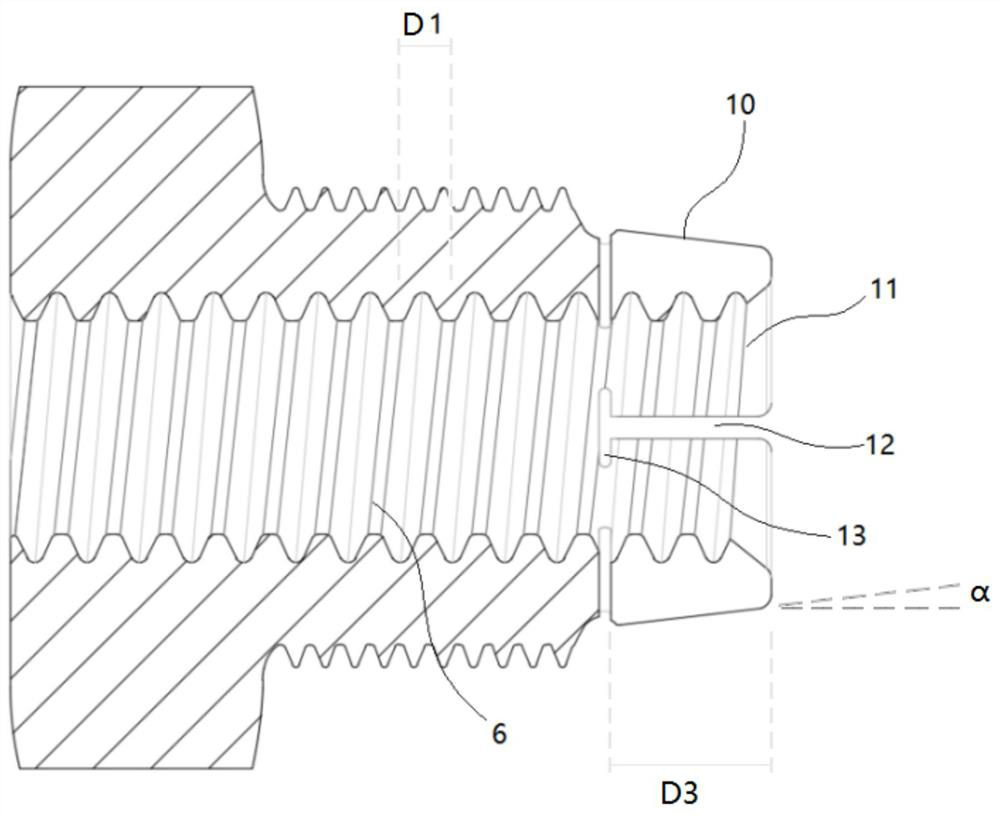

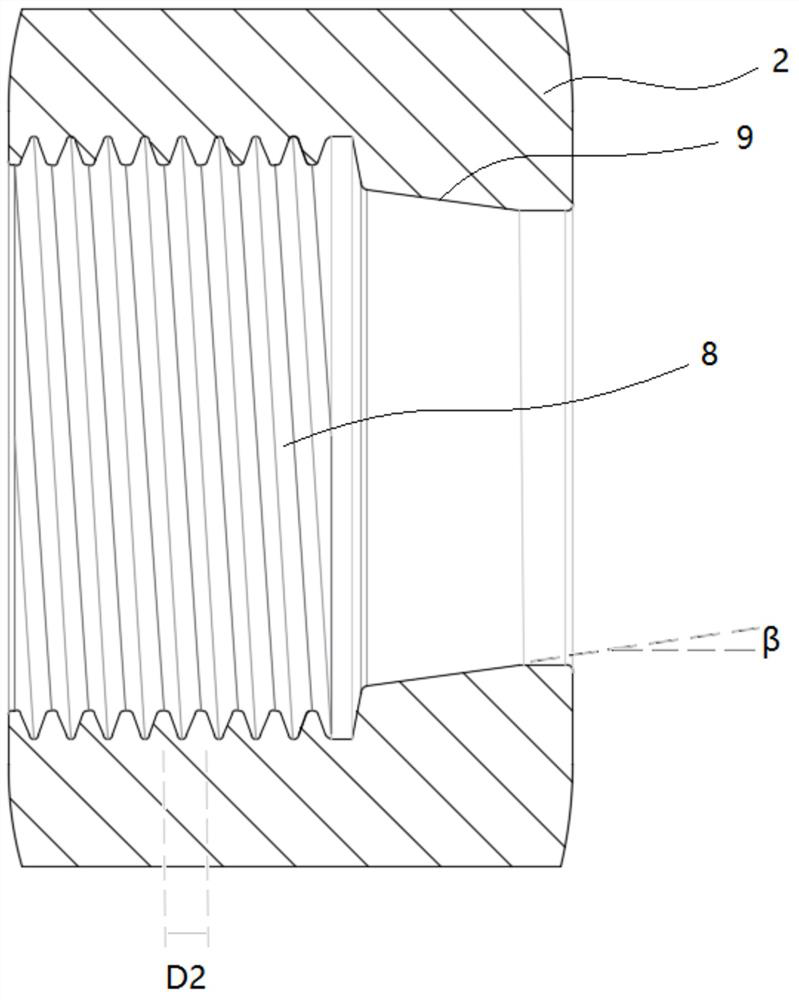

[0023] An anti-loosening nut disclosed in this embodiment is characterized in that it includes a main nut 1 and an auxiliary nut 2, and the main nut 1 is divided into multiple sections, which are respectively an outer hexagon section 3, an outer thread section 4 and a vertebral body section 5, The main nut 1 is connected in the axial direction, and the first internal thread 6 is provided inside. The external hexagon section 3, the external thread section 4 and the vertebral body section 5 are of an integrated structure, and the connection between the external thread section 4 and the vertebral body section 5 The interval passes through the inner arc section 7; the auxiliary nut 2 is in the shape of a hexagonal nut, and its axial direction is open, and the second internal thread 8 and the conical extrusion slope 9 are arranged in turn;

[0024] The vertebral body section 5 is conical, and its outer wall is a pressure slope 10. The vertebral body section 5 is composed of multi-lo...

Embodiment 2

[0032] An anti-loosening nut disclosed in this embodiment is characterized in that the multi-lobed pressure-receiving blocks 11 are evenly distributed in the circumferential direction along the axial direction of the main nut 1, and the main nut 1 and the auxiliary nut 2 are fastened, and the slope 9 is squeezed. Fully contact and closely fit with the pressure slope 10;

[0033] In this embodiment, the pressing surface pressure of the pressing slope surface 9 and the pressure receiving slope surface 10 is balanced, and the frictional force is embodied as a more balanced surface friction.

Embodiment 3

[0035] An anti-loosening nut disclosed in this embodiment is characterized in that the multi-lobed pressure blocks 11 are uniformly distributed in the circumferential direction, and their distribution axes are parallel to and do not intersect with the axis of the main nut 1, and are arranged eccentrically, and the main nut 1 and the auxiliary nut 1 are arranged eccentrically. In the fastened state of the nut 2, the extrusion slope 9 is fully in contact with the compression slope 10 and closely fits;

[0036] In this embodiment, the extrusion surfaces of the extrusion slope surface 9 and the compression slope surface 10 are unbalanced, and the shrinkage of the multi-lobe compression block 11 on the vertebral body segment is reflected in that one end is strong and the other end is weak, and the compression block 11 The inner shrinkage decreases evenly from the strong end to the weak end, which means that the friction force of the extrusion surface decreases evenly from the strong...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com