A design method of stiffness coefficient of elastic buffer casing

A technology of elastic cushioning and stiffness coefficient, applied in mechanical equipment, design optimization/simulation, engine components, etc., can solve the problems of rotor system and load-bearing casing impact damage, etc., to prolong the action time, reduce the impact force, The effect of ensuring safe and smooth work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] It should be noted that the embodiments in the present application and the features of the embodiments may be combined with each other in the case of no conflict. The present application will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

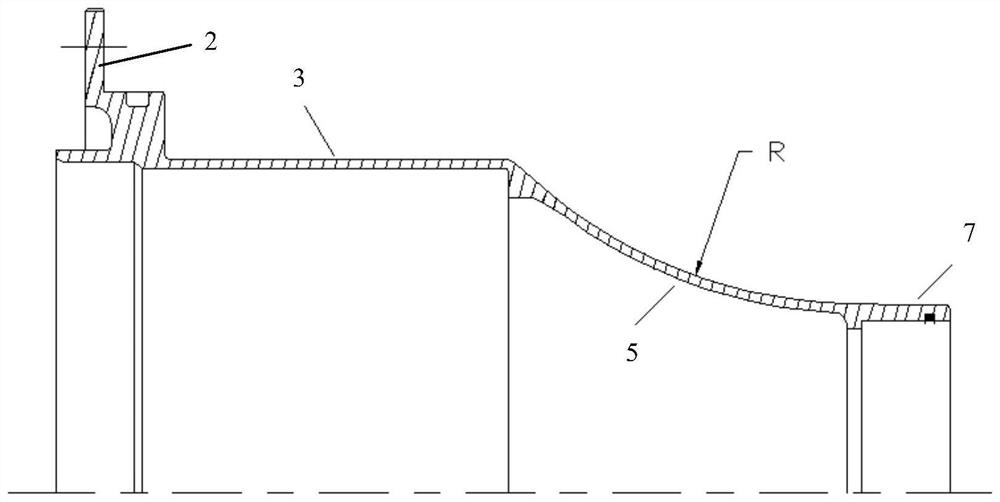

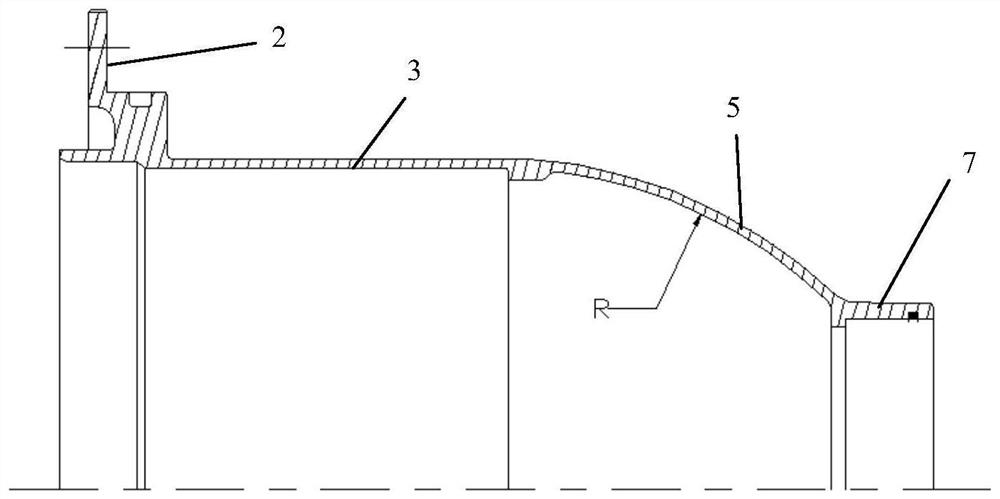

[0066] refer to figure 1 and figure 2 , the preferred embodiment of the present application provides an elastic buffer casing, the elastic buffer casing includes a flange section 9, a first bearing seat section 3, a transition section 5, and a second bearing seat section 7 in sequence along the axial direction ,

[0067] The flange section 9 is provided with a flange edge 2, and the flange edge 2 is fixedly connected with the outer casing 1 through bolts, so as to fix one end of the elastic buffer casing on the outer casing 1;

[0068] The inner hole of the first bearing seat segment 3 matches the outer circle of the first bearing 4 mounted on the power output sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com