Seamless combined frog

A seamless and frog technology, applied in the field of seamless combined frogs, can solve the problems of increasing manufacturing cost, difficulty in manufacturing, and many parts, etc., shortening the fitting length, reducing the difficulty of assembling, and improving the manufacturing accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

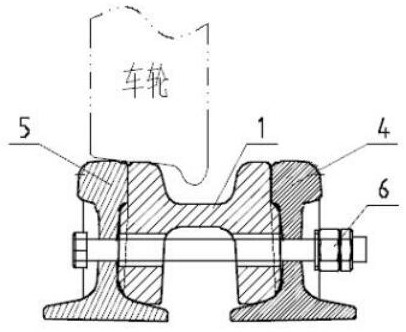

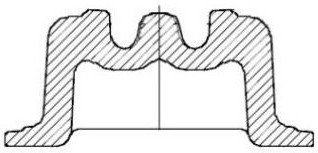

[0028] Embodiment 1: with reference to attached figure 1 . A seamless combined frog, comprising a fork core, wing rails, and fork heel rails, characterized in that: the front segment L1 of the fork core and the rear segment L2 of the fork core respectively have an The spacer iron 10, the spacer iron 9 before the fork center and the spacer iron 10 behind the fork center cooperate with the wing rails 4 and 5, the fork heel rails 2 and 3, and use the bolt pair 6 to realize fastening and installation. The wing rails refer to the left wing rail 4 and the right wing rail 5 . The fork heel rail refers to the left fork heel rail 2 and the right fork root rail 3 . The left wing rail 4, the right wing rail 5, the left fork heel rail 2, and the right fork heel rail 3 are bent, and the bending angle ranges G1, G2, G3, and G4 are respectively 0° to 35° ( G refers to rail). The rear tread surface 7 of the fork center and the front tread surface 8 of the fork center gradually decrease t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com