Washing-free ultraviolet curing coating and preparation method thereof

A technology for curing coatings and ultraviolet light, applied in antifouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc., which can solve the problem of unsatisfactory light absorption range and catalytic efficiency, easy detachment of nanoparticles, poor interaction, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

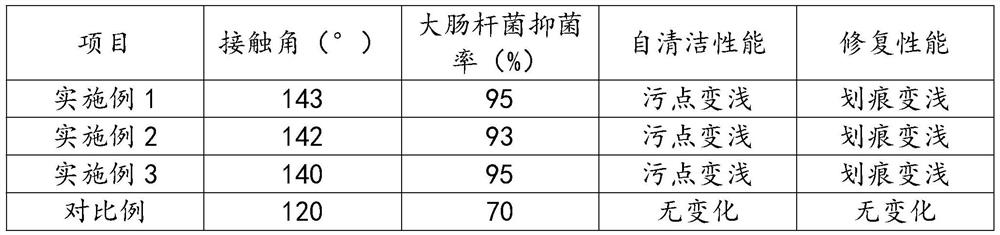

Examples

Embodiment 1

[0038] A wash-free ultraviolet light curing coating, comprising the following raw materials in parts by weight: 80 parts of composite emulsion, 5 parts of cleaning filler, 5 parts of repairing filler, 1 part of dispersant, 1 part of crosslinking agent and 1 part of photoinitiator;

[0039] The preparation method of this wash-free ultraviolet light curing coating comprises the following steps:

[0040] The first step is to add the composite emulsion into the reaction kettle, raise the temperature to 30°C, add the dispersant, cleaning filler, repair filler and crosslinking agent to the reaction kettle in sequence, and stir and mix for 2 hours at a rotation speed of 100r / min to obtain a mixture ;

[0041] In the second step, a photoinitiator is added to the mixture, and the rotation speed remains unchanged, and the stirring is continued for 30 minutes to obtain a no-clean UV-curable coating.

[0042] Wherein, the cleaning filler is made by the following steps:

[0043] Step A1....

Embodiment 2

[0057] A wash-free ultraviolet light curing coating, comprising the following raw materials in parts by weight: 90 parts of composite emulsion, 7 parts of cleaning filler, 7 parts of repairing filler, 1 part of dispersant, 1 part of crosslinking agent and 2 parts of photoinitiator;

[0058] The preparation method of this wash-free ultraviolet light curing coating comprises the following steps:

[0059] The first step is to add the composite emulsion into the reaction kettle, raise the temperature to 35°C, add the dispersant, cleaning filler, repair filler and crosslinking agent to the reaction kettle in sequence, and stir and mix for 3 hours at a rotation speed of 150r / min to obtain a mixture ;

[0060] In the second step, a photoinitiator is added to the mixture, and the rotation speed remains unchanged, and the stirring is continued for 30 minutes to obtain a no-clean UV-curable coating.

[0061] Wherein, the cleaning filler is made by the following steps:

[0062] Step A1...

Embodiment 3

[0076] A wash-free ultraviolet light curing coating, comprising the following raw materials in parts by weight: 100 parts of composite emulsion, 8 parts of cleaning filler, 8 parts of repairing filler, 1 part of dispersant, 1 part of crosslinking agent and 3 parts of photoinitiator;

[0077] The preparation method of this wash-free ultraviolet light curing coating comprises the following steps:

[0078] The first step is to add the composite emulsion into the reaction kettle, raise the temperature to 45°C, add the dispersant, cleaning filler, repair filler and crosslinking agent to the reaction kettle in sequence, and stir and mix for 4 hours at a rotation speed of 200r / min to obtain a mixture ;

[0079] In the second step, a photoinitiator is added to the mixture, and the rotation speed remains unchanged, and the stirring is continued for 30 minutes to obtain a no-clean UV-curable coating.

[0080] Wherein, the cleaning filler is made by the following steps:

[0081] Step A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com