High-elongation rubber for joint and preparation method of high-elongation rubber

A high-elongation, rubber technology, used in the field of high-elongation rubber for joints, can solve problems such as transition layer failure, improve elongation and adhesion performance, accelerate positive vulcanization time, and long-term anti-aging effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

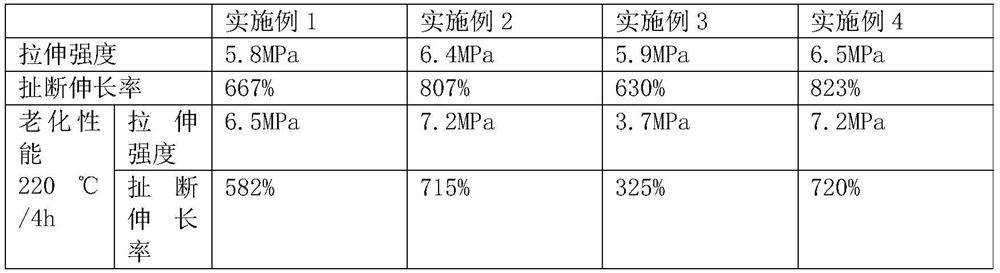

Examples

Embodiment 1

[0020] A high-elongation joint rubber, comprising the following components by weight: 45 parts of K740 rubber, 45 parts of 4045 rubber, 10 parts of liquid ethylene-propylene rubber T65, 20 parts of zinc oxide, 50 parts of carbon black N330, paraffin wax 15 parts of oil 2280, 1.0 parts of anti-aging agent RD, 1.0 parts of anti-aging agent MB, 1 part of anti-aging agent MC, 3 parts of vulcanizing agent DCP.

[0021] A preparation method of high elongation rubber for joints:

[0022] (1) Preparation of one stage of mixed rubber: Take K740 rubber 225g, 4045 rubber 225g, liquid ethylene propylene rubber T65 50g, zinc oxide 100g, carbon black N330 250g, paraffin oil 75g, antioxidant RD 7.5g, antioxidant MB 7.5g , anti-aging agent MC 5g, vulcanizing agent DCP 15g; press K740 rubber and 4045 rubber 1min-zinc oxide 1min-antiaging agent 1min-carbon black+paraffin oil 2min-vulcanizing agent DCP 1min when the internal temperature reaches 60°C with an internal mixer Sequentially add and m...

Embodiment 2

[0025] A high-elongation joint rubber, comprising the following components by weight: 50 parts of K740 rubber, 40 parts of 4045 rubber, 10 parts of liquid ethylene-propylene rubber T65, 20 parts of zinc oxide, 50 parts of carbon black N330, paraffin wax 15 parts of oil 2280, 1.5 parts of anti-aging agent RD, 1.5 parts of anti-aging agent MB, 1 part of anti-aging agent MC, 3 parts of vulcanizing agent DCP.

[0026] A preparation method of high elongation rubber for joints:

[0027] (1) Preparation of one stage of mixed rubber: Take K740 rubber 250g, 4045 rubber 200g, liquid ethylene propylene rubber T65 50g, zinc oxide 100g, carbon black N330 250g, paraffin oil 75g, antioxidant RD 7.5g, antioxidant MB 7.5g , anti-aging agent MC 5g, vulcanizing agent DCP 15g, when the internal temperature reaches 60°C with an internal mixer, add K740 rubber and 4045 rubber 1min-zinc oxide 1min-antiaging agent 1min-carbon black+paraffin oil 2min-vulcanizing agent 1min in sequence Mix and knead t...

Embodiment 3

[0030] A high-elongation joint rubber, comprising the following components by weight: 50 parts of K740 rubber, 30 parts of 4045 rubber, 20 parts of liquid ethylene propylene rubber, 20 parts of zinc oxide, 55 parts of carbon black N330, paraffin oil 15 parts of 2280, 1.5 parts of anti-aging agent RD, 1.5 parts of anti-aging agent MB, 1 part of anti-aging agent MC, 3 parts of vulcanizing agent DCP.

[0031] A preparation method of high elongation rubber for joints:

[0032] (1) Preparation of one stage of mixed rubber: Take K740 rubber 250g, 4045 rubber 150g, liquid ethylene propylene rubber T65 100g, zinc oxide 100g, carbon black N330 250g, paraffin oil 75g, antioxidant RD 7.5g, antioxidant MB 7.5g , anti-aging agent MC 5g, vulcanizing agent DCP 15g; when the internal temperature reaches 60°C with an internal mixer, add solid rubber 1min-zinc oxide 1min-antiaging agent 1min-carbon black+paraffin oil 2min-vulcanizing agent DCP 1min in order to mix and knead Make the rubber mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com