Method for preparing NO2 gas oxidizing agent through metal nitrate pyrolysis

A metal nitrate and nitrate technology, applied in the field of metal nitrate, can solve the problems of large equipment investment, high equipment cost, complex process, etc., and achieve the effects of increasing economic benefits, improving production efficiency, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

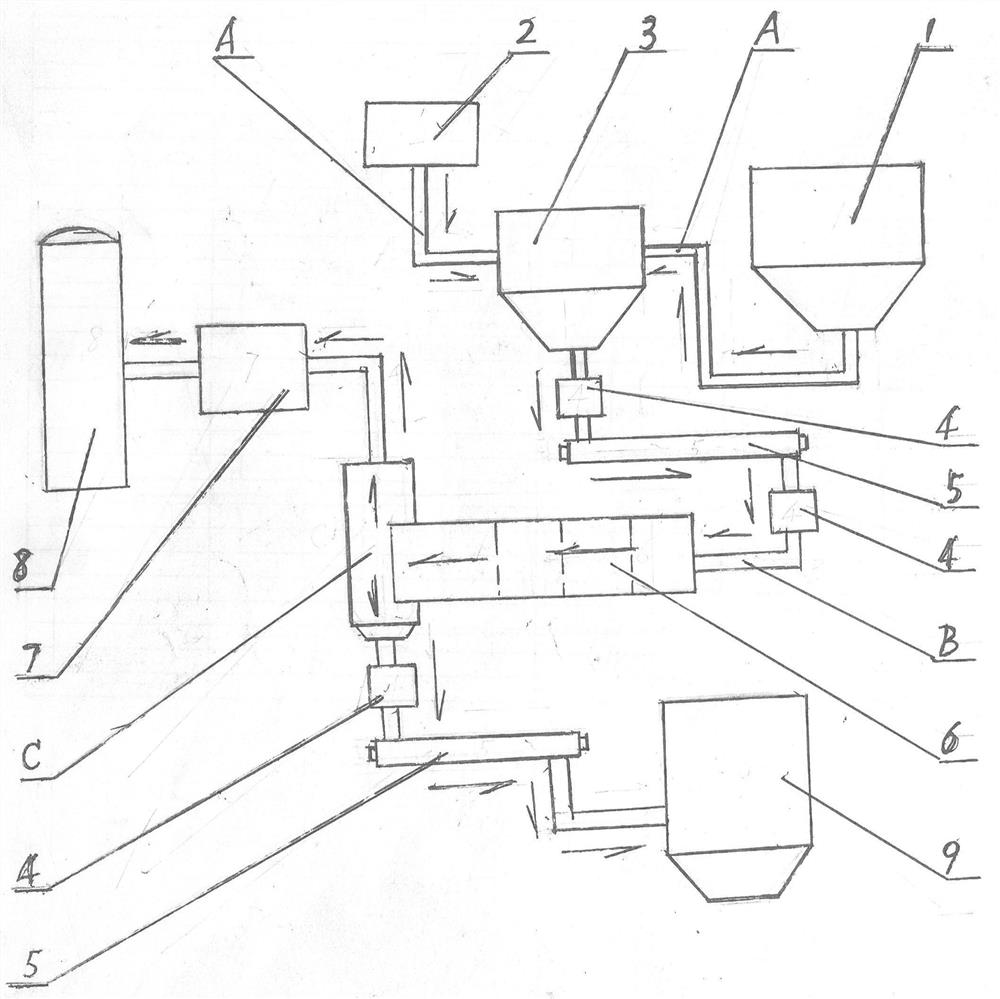

[0013] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0014] refer to figure 1 , the structure and working principle of the present invention are in the described method, comprising nitrate silo 3, air compressor 2, metal nitrate storage bin 1, air lock valve 4, conveyor 5, tubular microwave pyrolyzer 6. Screw vacuum pump 7. NO 2 Storage tank 8, metal oxide storage bin 9, the upper end of the nitrate storage bin 3 is connected to the air compressor 2 and the metal nitrate storage bin 1 through the gas delivery pipe A respectively, and the air compressor 2 is connected to the air compressor 2 through the gas delivery pipe A. The air is conveyed in the nitrate silo 3 to maintain the pressure in the nitrate silo 3, and the nitrate powder C is transported to the nitrate silo 3, the lower end of the nitrate silo 3 is connected with the upper end of the air lock valve 4, and the lock The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com