Compression molding equipment for tea cakes

A compression molding and equipment technology, which is applied in the field of tea cake pressing and molding equipment, can solve the problems of low processing efficiency and long time-consuming tea cake processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

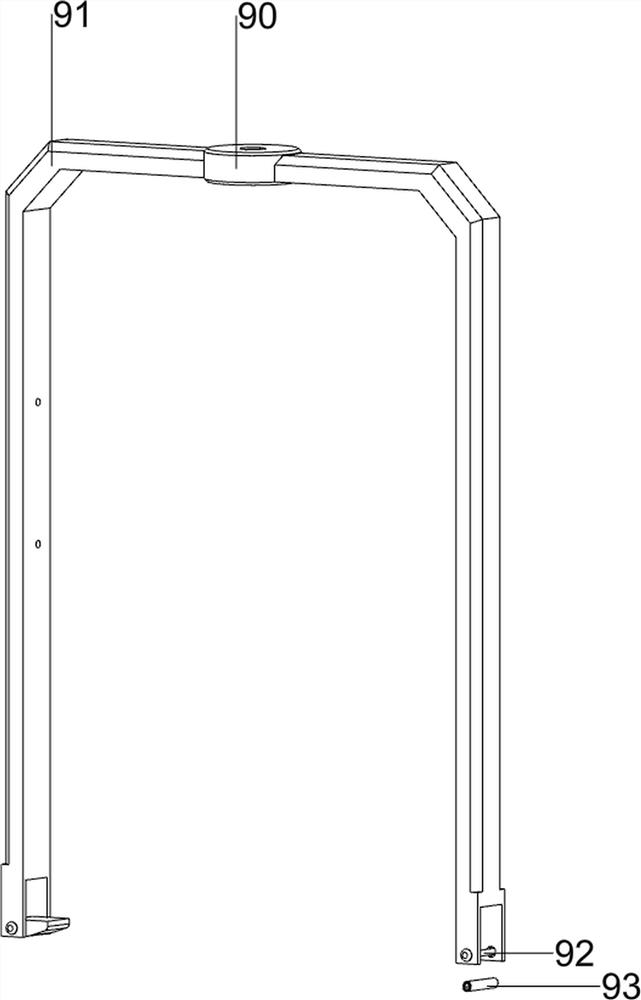

[0026] A kind of equipment for pressing and forming tea cakes, such as Figure 1-3 As shown, it includes a bottom plate 1, a first support foot 2, a placement frame 3, a molding die 4, a fixed rod 5, a cylinder 6, a first connecting rod 7, a lower pressing block 8, an upper pull mechanism 9 and an auxiliary discharge mechanism 10 The first supporting feet 2 are evenly arranged on the front and rear sides of the right part of the bottom plate 1, and a placing frame 3 is connected between the first supporting feet 2, a forming mold 4 is arranged on the left side of the placing frame 3, and a fixing rod 5 is arranged in the middle of the placing frame 3 , the fixed rod 5 is provided with a cylinder 6, the bottom of the cylinder 6 is provided with a first connecting rod 7, the bottom of the first connecting rod 7 is provided with a lower pressing block 8, the first connecting rod 7 is provided with a pull-up mechanism 9, and the left side of the bottom plate 1 An auxiliary dischar...

Embodiment 2

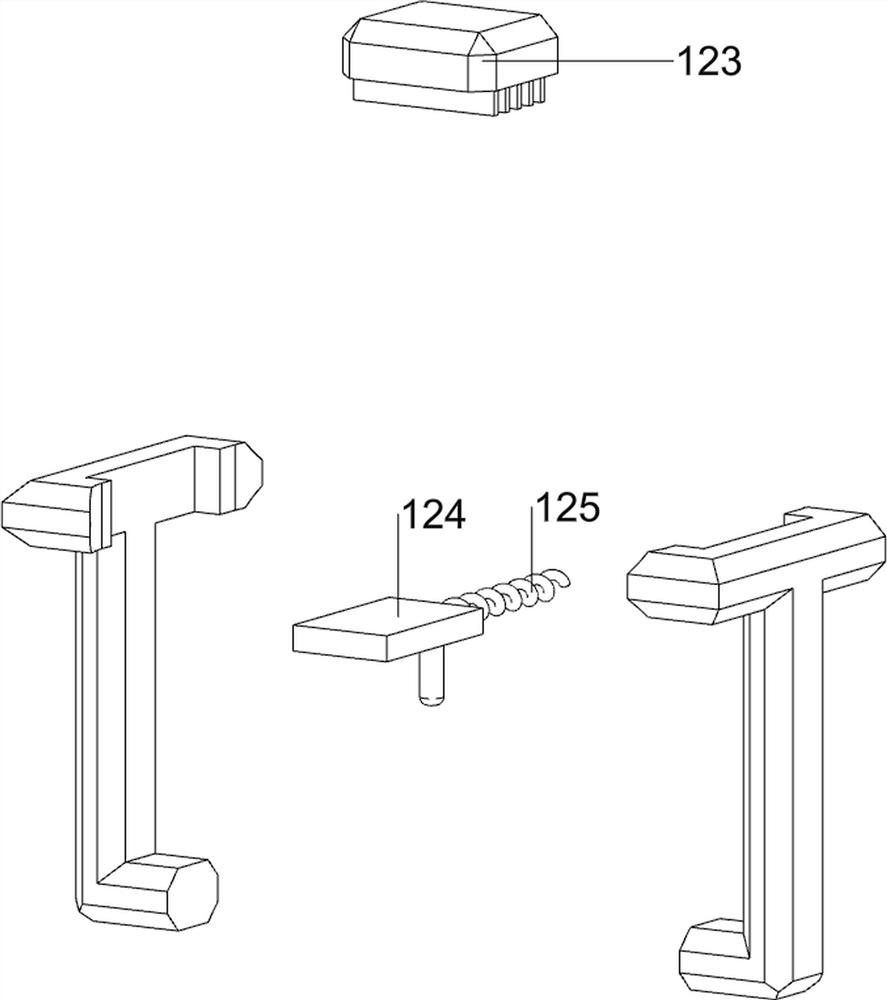

[0031] On the basis of Example 1, such as Figure 4-8 As shown, a blanking mechanism 11 is also included, and the blanking mechanism 11 includes a first receiving box 110, a conduit 111, a limit case 112, a first rack 113, a first fixed frame 114, a first gear 115 and a second The rack 116 is slidingly connected to the right side of the placement frame 3 with a first receiving box 110, the left side of the first receiving box 110 is provided with a guide tube 111, the left side of the guide tube 111 is provided with a limit case 112, and the left front side of the top of the rack 3 is slidingly connected There is a first tooth bar 113, and the left front side of the placement frame 3 is provided with two first fixed mounts 114, the first fixed mounts 114 are rotatably connected with a first gear 115, and the second connecting rod 91 on the front side is provided with a first gear 115. Two racks 116.

[0032] When people need to unload, the tea leaves are first poured into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com