Sliding rail type screen shielding device

A shielding device, slide rail type technology, applied in the field of slide rail screen shielding device, can solve the problems of shielding, safety and stability, etc., reduce the workload of repeated disassembly and assembly and exposure dose, and meet the requirements of rapid installation and demolition, strong stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

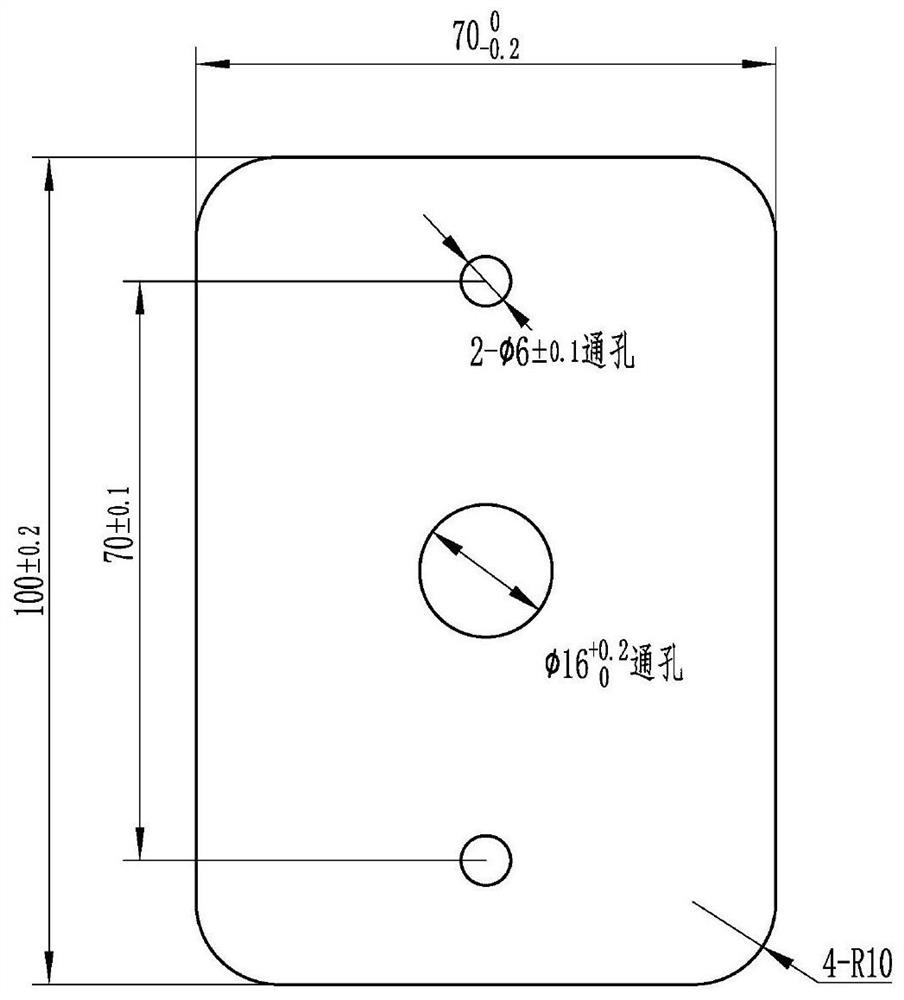

Image

Examples

Embodiment 1

[0082] see figure 1 , a sliding rail type screen shielding device, including a movable bracket and 12 screen shielding modules 9 .

[0083] The movable support includes 1 frame 1, 4 slide rails 5, 24 sliders 6, 24 hoisting upper parts 7, 24 hoisting lower parts 8, 2 wall leg parts 4, and 2 bottom legs Component 12, and 2 universal wheels 11.

[0084] The frame 1 is integrally manufactured from several square tubes, including a top beam, a bottom beam, a middle beam, a left side beam and a right side beam, and the top beam, the left side beam, the bottom beam and the right side beam The beams are sequentially connected end to end to form a rectangular frame, and the middle part of the inner cavity of the rectangular frame is provided with a middle beam. Specifically, the wall thickness of the square tube is 3mm; the frame 1 has a length, width, and height of 1100mm×70mm×1500mm; The horizontal center plane of the middle beam is 750mm from the bottom surface of the bottom beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com