Rack system for inserting electrical printed circuit boards

A technology of assembly system and printed circuit, applied in the direction of electrical components, electrical equipment structural parts, electrical equipment housing/cabinet/drawer, etc., to improve the effect of clamping or holding and electrical contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

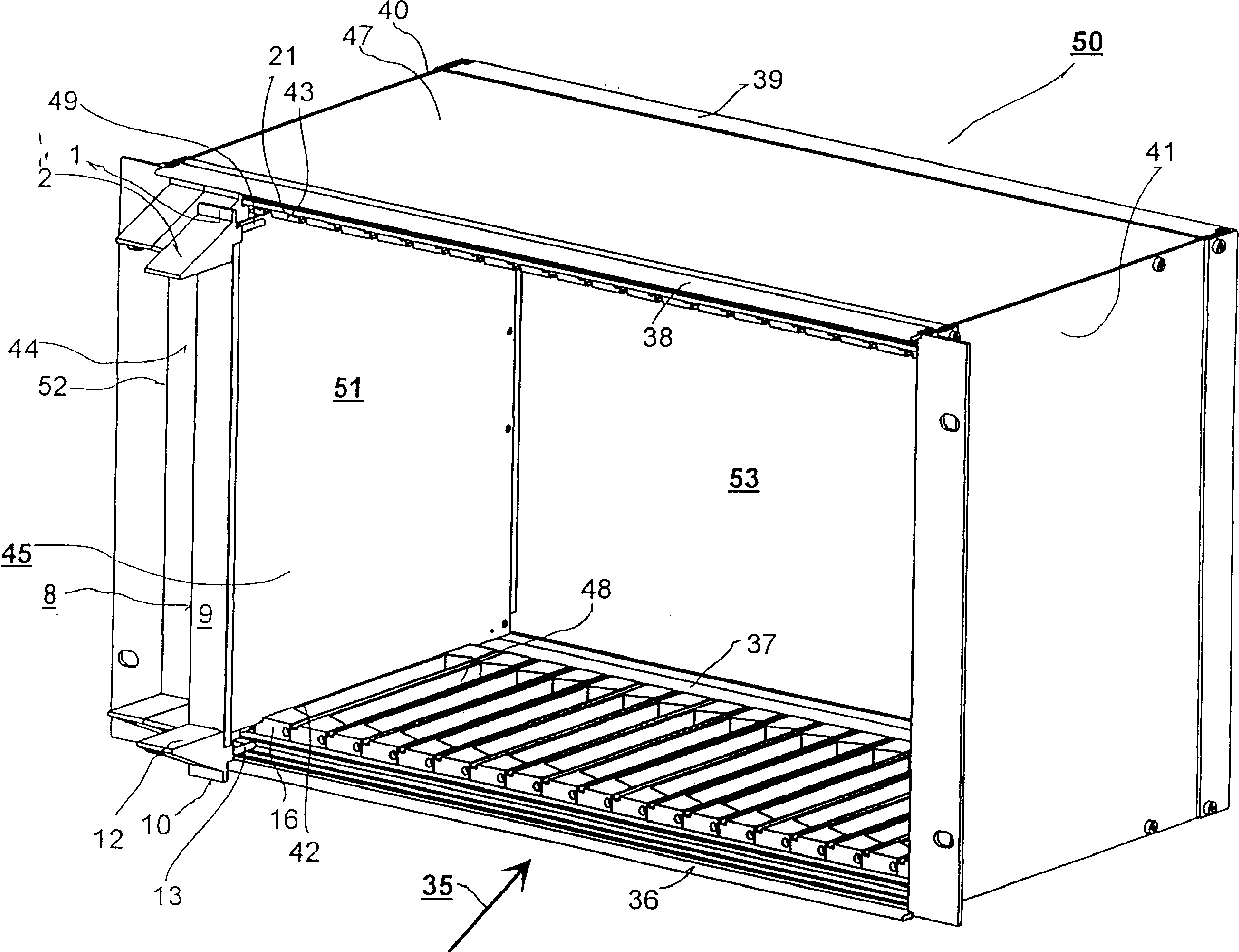

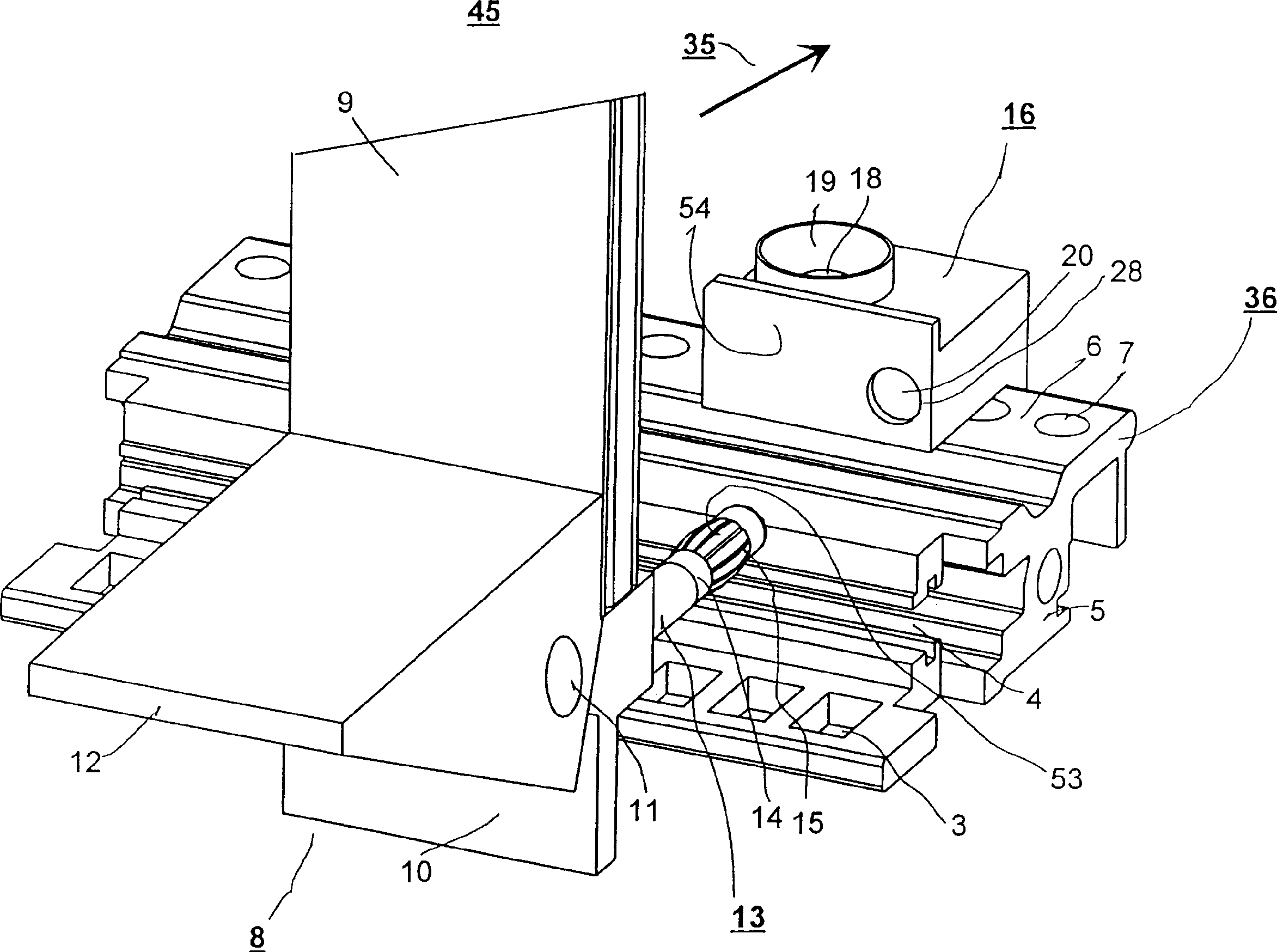

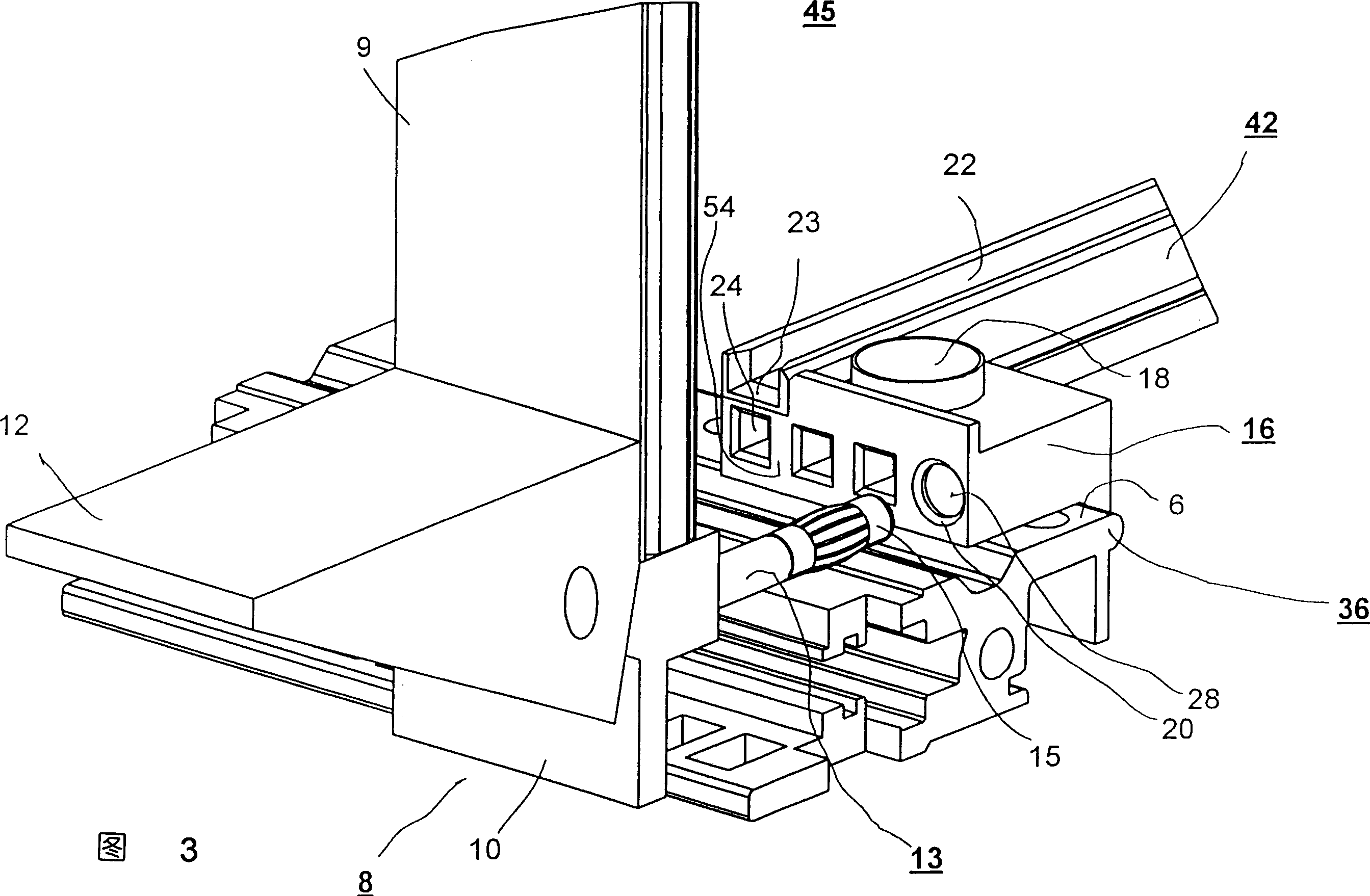

[0033] already described in part figure 1 In this case, the printed circuit insert 51 on the front side element 8 and the associated mounting position 45 has been provided according to the invention with insertable and extractable centering and contact elements 13 , 49 which face the insertion side 35 of the component frame 50 protrude. The centering and contact elements 13 , 49 are mounted, for example, respectively on a lower corner block 10 and an upper corner block 1 , wherein the corner blocks 10 , 1 are fastened to the front end of a front side panel 9 . These corner blocks are also used to hold a lower lever handle 12 and an upper lever handle 2 , with which the insertion and extraction of the unit consisting of the front element 8 and the printed circuit insert 51 is facilitated. The corner block with the centering and contact elements and the front side plate are made of electrically conductive material like the transverse connection rails.

[0034] Both the lower t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com