Optical fiber device and method for detecting reducing sugar

A technology of optical fiber and optical fiber bundle, which is applied in the field of analysis and sensing, can solve the problems of expensive atomic absorption spectrometer equipment, cumbersome operation steps, and expensive instruments and equipment, and achieve broad commercial application prospects, simplify assembly procedures, and simplify complex designs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

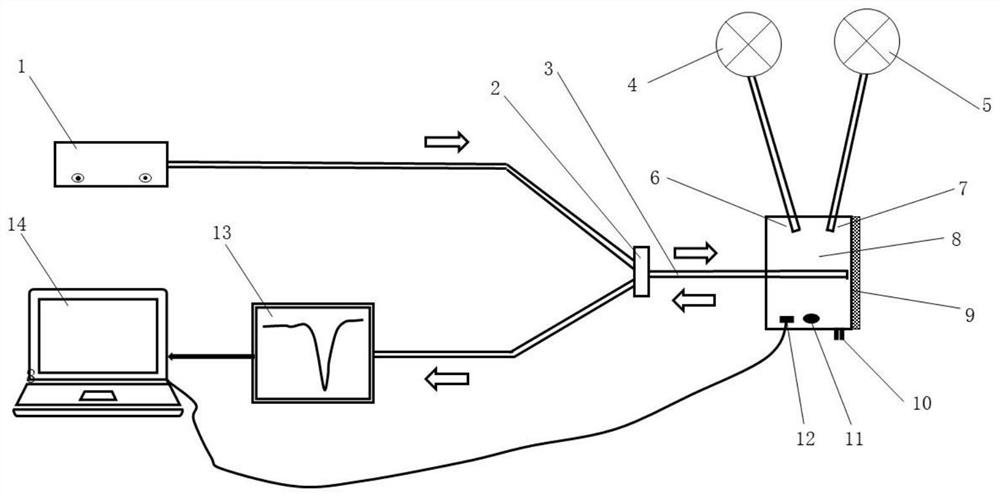

[0041] Such as figure 1 As shown, an optical fiber device for detecting reducing sugars includes a sample mixing reaction cell 8 , a reflecting mirror 9 , an optical fiber bundle 3 , an optical fiber laser 1 and a spectrum analyzer 13 .

[0042] The top of the sample mixing reaction pool 8 has a test liquid inlet 6 and a reaction reagent inlet 7, and the bottom of one side has a waste liquid discharge port 10 (equipped with a valve or a stopper);

[0043] The first flow syringe pump 4 pumps the liquid to be tested from the liquid to be tested inlet 6 into the sample mixing reaction pool 8;

[0044] The second flow injection pump 5 pumps the reaction reagent into the sample mixing reaction cell 8 from the reaction reagent inlet 7 .

[0045] The sample mixing reaction pool 8 is provided with a magnetic stirrer 11 and a temperature control device 12; the temperature control device 12 can be connected to a computer 14, and the computer 14 issues temperature control instructions. ...

Embodiment 2

[0059] Use the device in embodiment 1 to measure the reducing sugar sample liquid extracted from wheat flour:

[0060] (1) Use acetone, ethanol, and water to wash the sample mixing reaction tank 8 and the pipeline channel used for sample injection in sequence;

[0061] (2) Under the action of the first flow syringe pump 4, 5ml reducing sugar sample solution is injected into the sample mixing reaction tank 8 through the liquid to be tested inlet 6; under the action of the second flow syringe pump 5, 2.5ml containing The reaction reagents of 0.27M copper sulfate pentahydrate, 2.5 μL concentrated sulfuric acid, 1.23M potassium sodium tartrate and 2.5M sodium hydroxide are injected into the sample mixing reaction pool 8 through the reaction reagent inlet 7; Next, the reducing sugar sample solution and the reaction reagent are fully mixed in the sample mixing reaction cell 8;

[0062] (3) Control the temperature control device 12 through the computer 14 to adjust the temperature, ...

Embodiment 3

[0066] The reducing sugar sample liquid extracted from potatoes is measured using the device in Example 1:

[0067] (1) Use acetone, ethanol, and water to wash the sample mixing reaction tank 8 and the pipeline channel used for sample injection in sequence;

[0068] (2) Under the action of the first flow syringe pump 4, 5ml of the reducing sugar sample solution is injected into the sample mixing reaction tank 8 through the sample inlet 6 of the liquid to be tested; under the action of the second flow syringe pump 5, 5ml contains 0.028M The reaction reagent of 3,5-dinitrosalicylic acid, 0.650M sodium hydroxide and 75 μL glycerol is injected into the sample mixing reaction pool 8 through the reaction reagent inlet 7; under the action of the magnetic stirrer 11, the reduced The sugar sample solution and the reaction reagent are fully mixed in the sample mixing reaction tank 8;

[0069] (3) Control the temperature control device 12 through the computer 14 to adjust the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com