Gas engine intake system, gas engine and automobile

A gas engine and air intake system technology, applied in combustion engines, fuel air intakes, internal combustion piston engines, etc., can solve the problem of poor consistency of burst pressure of each cylinder, failure to meet development target requirements, and the impact of burst pressure on intake uniformity. It can improve the rationality of design, reduce the difficulty of development, and achieve the effect of high design freedom.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

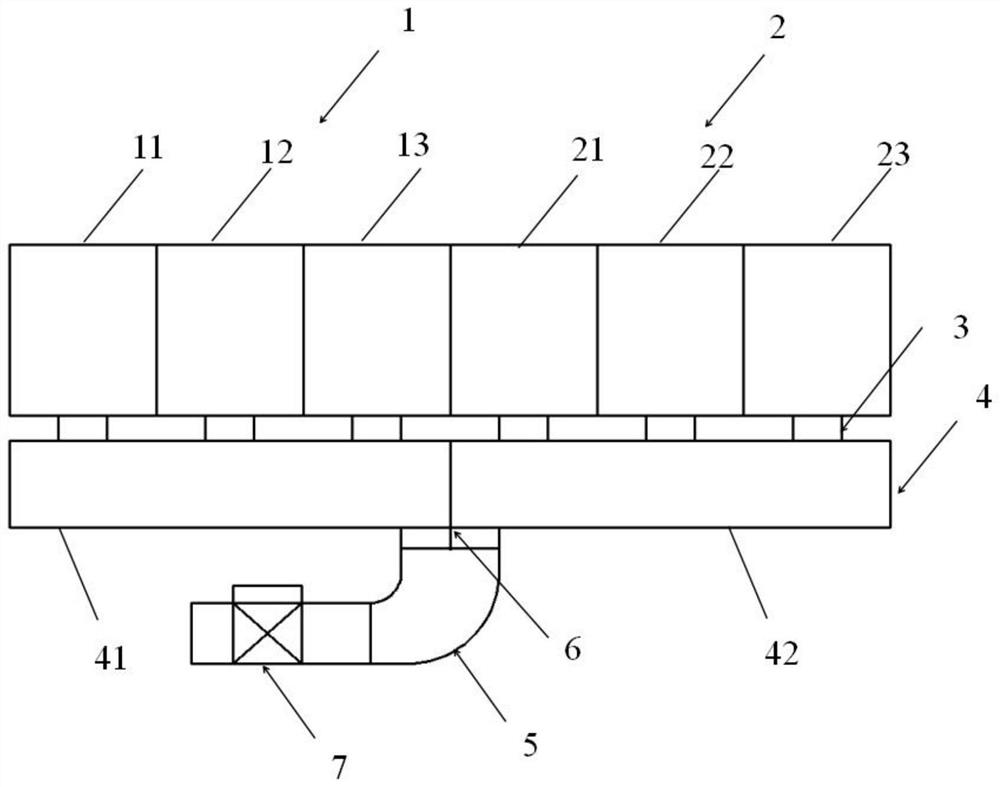

[0030] Embodiment 1 provides a gas engine intake system, such as figure 1 As shown, the system shown includes: a first cylinder group 1, a second cylinder group 2, a plurality of fuel injectors 3, an intake manifold 4, an intake elbow 5 and a spacer 6;

[0031] The first cylinder group 1 includes at least one cylinder, the second cylinder group 2 includes at least one cylinder, and the cylinders in the first cylinder group 1 and the second cylinder group 2 are all connected to the fuel injector 3 are provided in one-to-one correspondence, the intake end of the fuel injector 3 is connected to the intake manifold 4, and the intake end of the intake manifold 4 is connected to the intake elbow 5;

[0032] The spacer 6 is arranged in the middle of the intake manifold 4, and divides the intake manifold 4 into a first intake portion 41 and a second intake portion 42, the first intake portion 41 is used to provide Gas is supplied to the first cylinder group 1 , and the second air int...

Embodiment 2

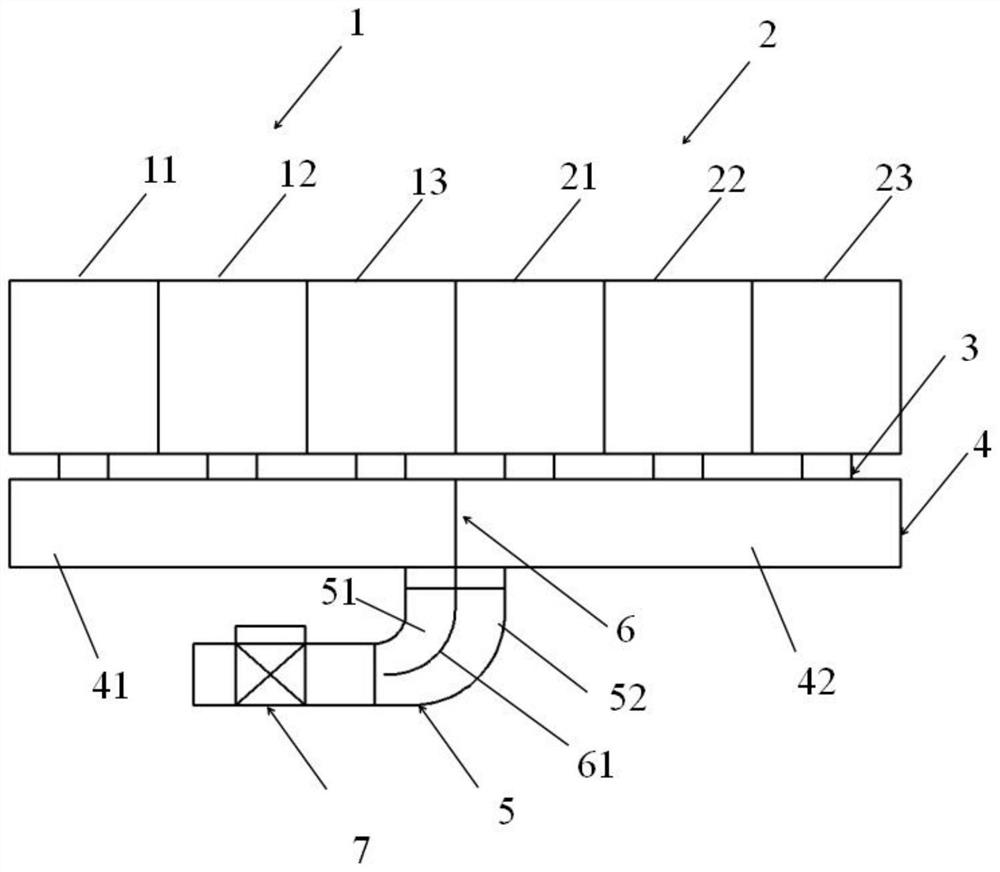

[0049] The second embodiment provides a gas engine intake system, such as figure 2 As shown, the system shown includes: a first cylinder group 1, a second cylinder group 2, a plurality of fuel injectors 3, an intake manifold 4, an intake elbow 5 and a spacer 6;

[0050] The first cylinder group 1 includes at least one cylinder, the second cylinder group 2 includes at least one cylinder, and the cylinders in the first cylinder group 1 and the second cylinder group 2 are all connected to the fuel injector 3 are provided in one-to-one correspondence, the intake end of the fuel injector 3 is connected to the intake manifold 4, and the intake end of the intake manifold 4 is connected to the intake elbow 5;

[0051] The spacer 6 is arranged in the middle of the intake manifold 4, and divides the intake manifold 4 into a first intake portion 41 and a second intake portion 42, the first intake portion 41 is used to provide Gas is supplied to the first cylinder group 1 , and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com