Standard wedge intelligent matching method

A matching method and standard technology, applied in computational models, biological models, instruments, etc., can solve the problems of low design efficiency and high repeatability of wedge work, achieve high speed and efficiency, improve design efficiency and rationality, eliminate The effect of repetitive work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

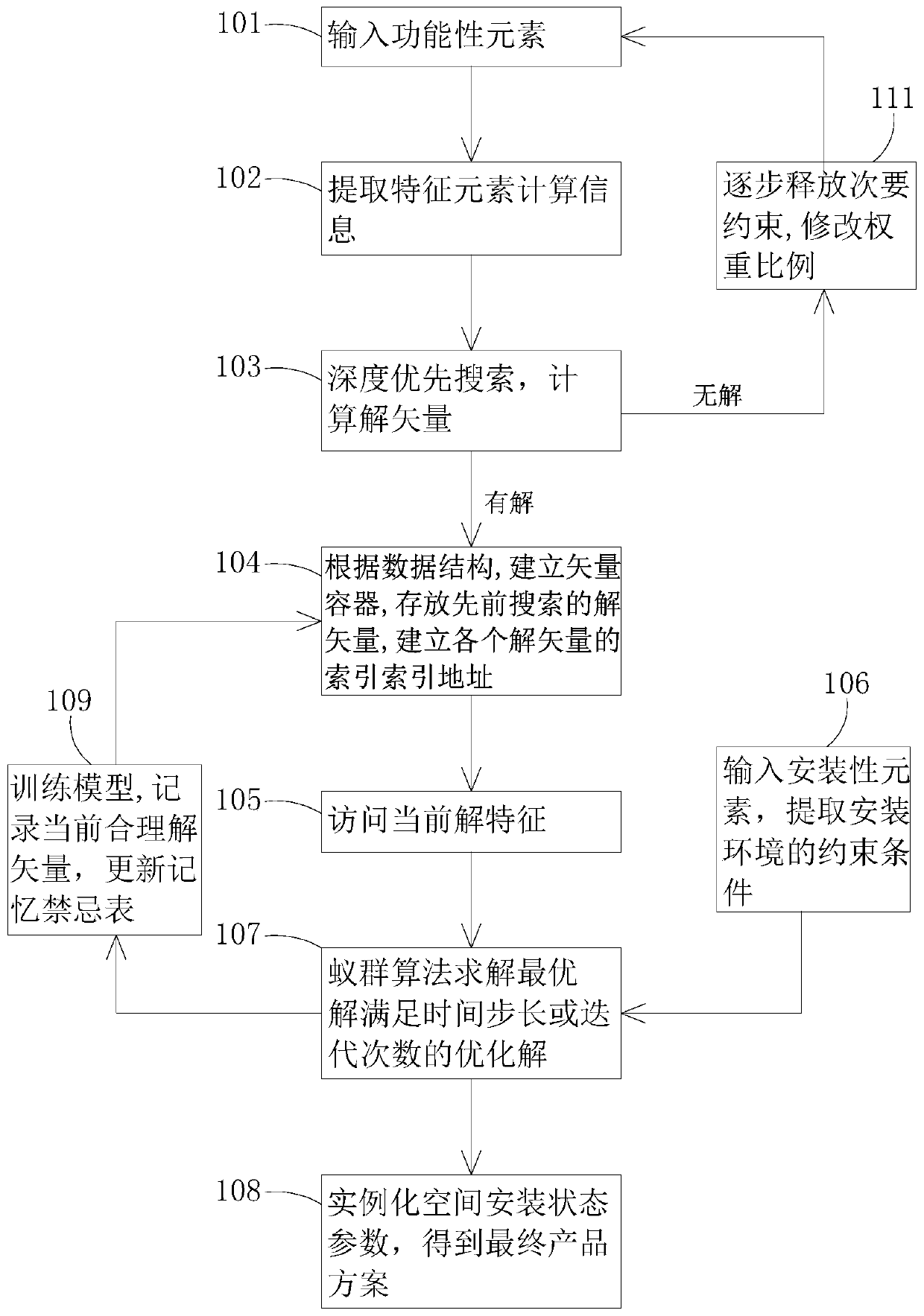

[0027] Below in conjunction with accompanying drawing, invention is described in further detail.

[0028] figure 1 A standard wedge intelligent matching method according to an embodiment of the present invention is schematically shown.

[0029] refer to figure 1 , a standard wedge intelligent matching method includes the following steps:

[0030] Step 101: input functional elements; the functional input elements described in step A include: the upper-level calculated working characteristic line area constraints, standard CAM (computer Aided Manufacturing, computer-aided manufacturing) orientation constraints, standard CAM external attribute information, standard CAM installation Surface installation form, etc.

[0031] Step 102: Extract feature element calculation information; the working feature line area often contains multiple domains, each domain is composed of subdivided curve segments, and the feature line area is fitted according to the smallest rectangle; extract th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com