Automatic generation method for mold insert boundary

An automatic generation and inserting technology, applied in 3D modeling, CAD numerical modeling, image data processing, etc., can solve the problems of time-consuming, labor-intensive, low design efficiency, and high repetition of designers' work, and achieve fast learning and knowledge accumulation. , The effect of improving adaptability and rationality, improving design efficiency and rationality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, invention is described in further detail.

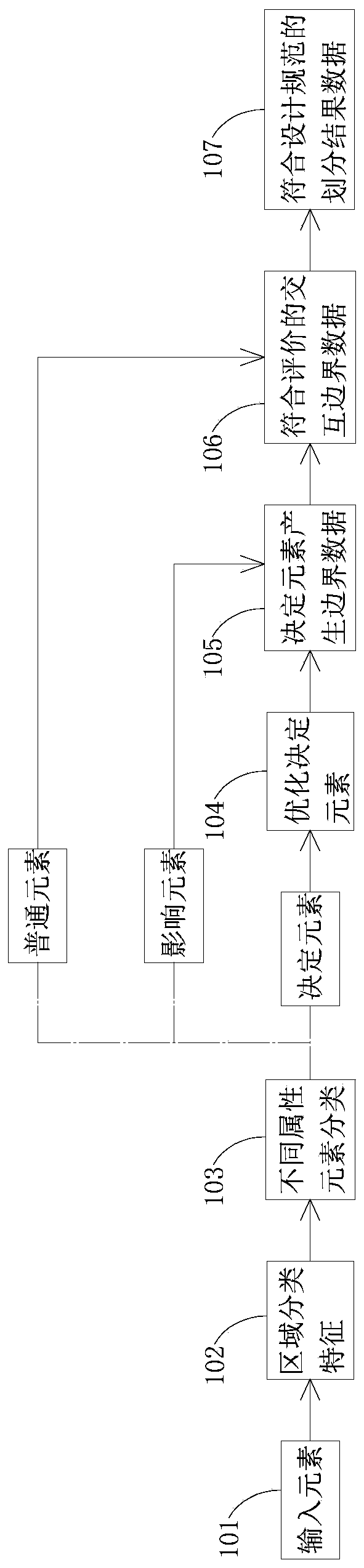

[0024] figure 1 A schematic flowchart of a method for automatically generating mold insert boundaries according to an embodiment of the present invention is schematically shown.

[0025] refer to figure 1 , a method for automatically generating a mold insert boundary, comprising the following steps:

[0026] Step 101: Input elements; the elements include point sets (PointCloud) or other structure black area sets (BlankOther) of the mold. The input elements are obtained from the feature lines that need to divide the insert.

[0027] Step 102: Regional classification features: According to the constraints of different regions, recalculate the fused element feature set (MergePointCloud) by using the merge selection algorithm.

[0028] Step 103: Classification of elements with different attributes: According to the design classification mechanism, such as: size constraints, logic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com