Integrate the layout of subway stations and sections in a single section and mechanized rapid construction methods

A technology for subway stations and construction methods, applied in the fields of earth drilling, underground chambers, shaft equipment, etc., which can solve problems such as complex technology and process conversion, city image and traffic, large impact on business, and labor-intensive consumption, etc., to achieve The effect of reducing the times of departure, arrival, dismantling and installation of shield tunneling, reducing the amount of abandoned temporary works, and reducing the use of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

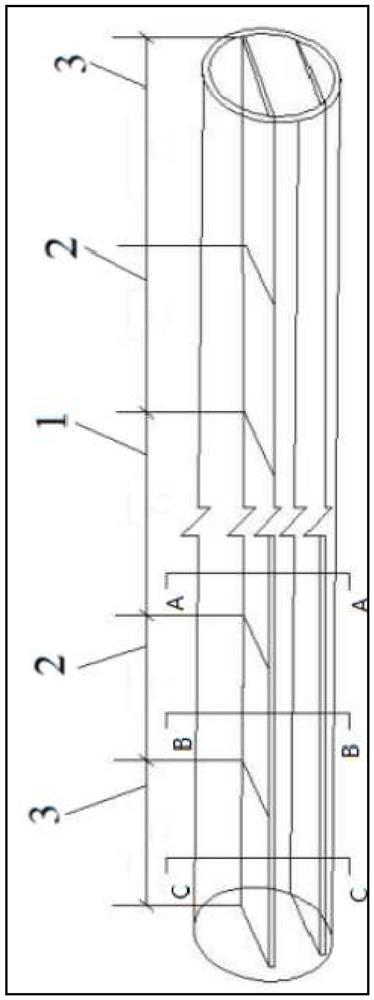

[0100] A layout that integrates subway stations and sections in a single section, such as Figures 1 to 4 As shown in the figure, including large-diameter single-hole tunnels that meet the requirements of the double-layer subway tunnel boundary and the building boundary of the station platform hall, the station hall section 2 is set on both sides of the platform section 1 to meet the functions of checking access and buffering passenger flow; The underground shopping mall section 3 is extended on both sides;

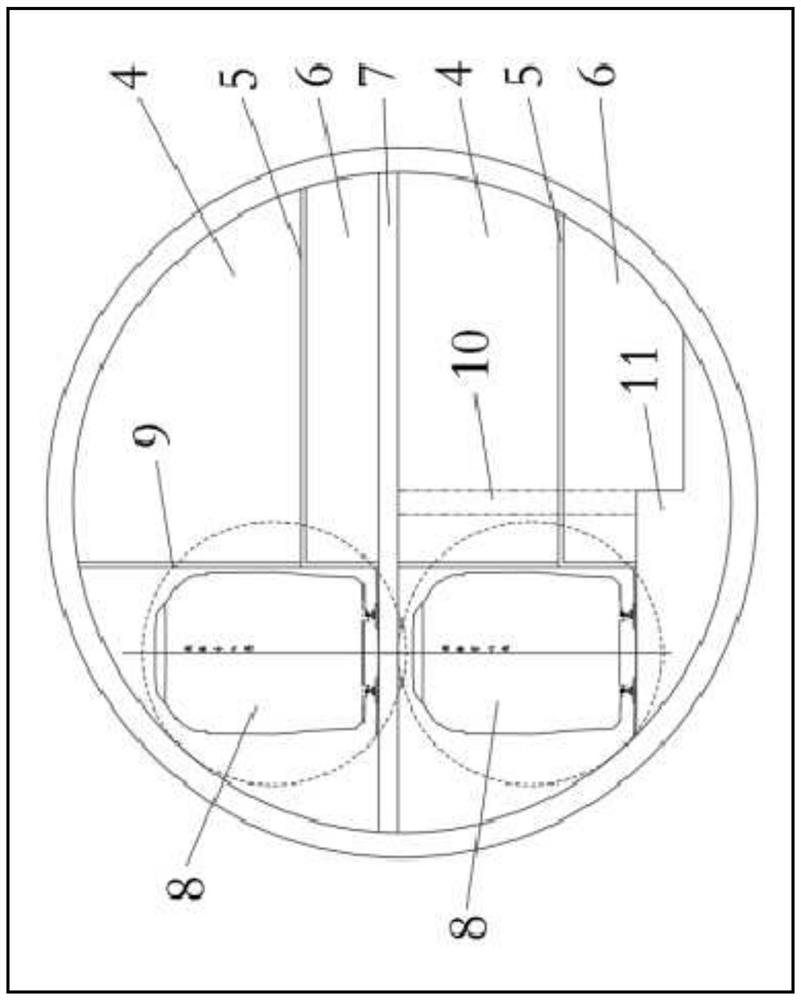

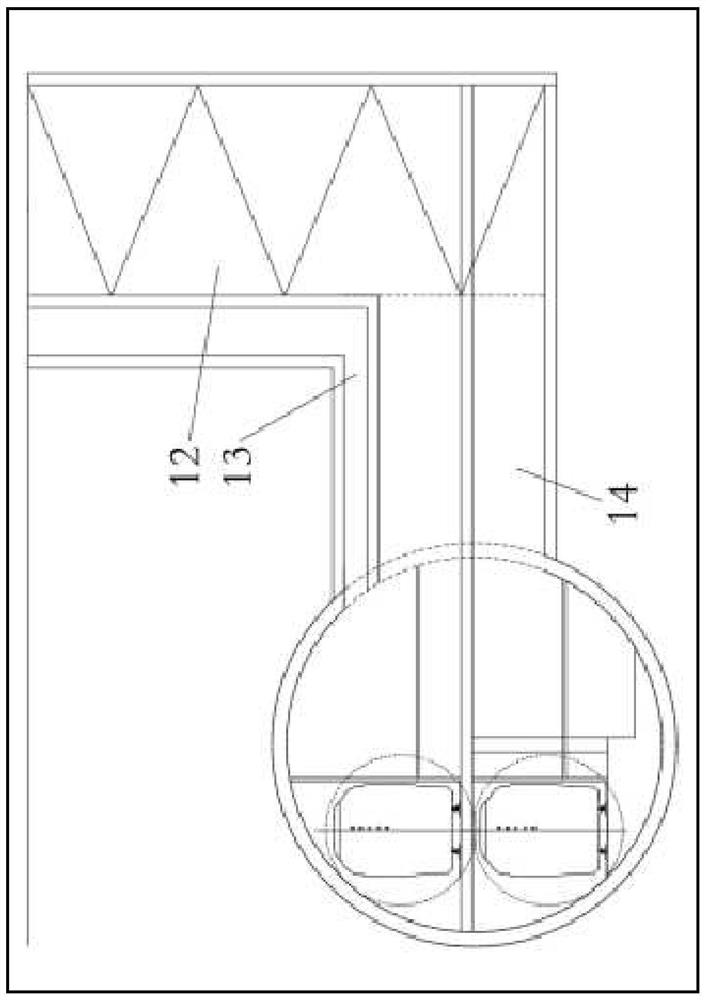

[0101] A vertical support wall 10, a horizontal partition plate 7, a train boundary 8 and a safety screen door 9 are arranged in the large-diameter single-hole tunnel to separate the upper and lower lines. 5 The upper side is the personnel activity layer 4, the personnel activity layer 4 can be the platform layer, the station hall layer, the urban corridor layer, the civil air defense layer or the shopping mall layer, etc. The lower side of the platform plate 5 is the pip...

Embodiment 2

[0104] A mechanized rapid construction method integrating the layout of subway stations and sections in a single section, comprising the following steps:

[0105] ①If figure 1 As shown in the figure, a large-diameter shield that meets the requirements of the double-layer subway tunnel boundary and the building boundary of the station platform and hall is adopted, and a tunnel boring machine is used to construct several sections and stations at one time;

[0106] The tunnel boring machine is selected to meet the subway boundary regulations for the upper and lower layers of the two subway trains; the subway boundary is divided into vehicle boundary, equipment boundary and building boundary. The vehicle boundary is divided into the interval vehicle boundary and the vehicle boundary within the calculated length of the platform. Circular tunnel building boundaries, the calculation of the size of each boundary shall comply with the "Code for Metro Design" GB50157-2013. Combined wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com