Mechanical automatic lifting slipway scaffold assembly

A technology of automatic lifting and scaffolding, which is applied in the direction of berth, dry dock, transportation and packaging, etc., can solve the problems of deck surface damage, affecting mechanical properties, support removal and grinding workload, etc., to reduce ship manufacturing costs and improve construction Efficiency and the effect of reducing the workload of on-site construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

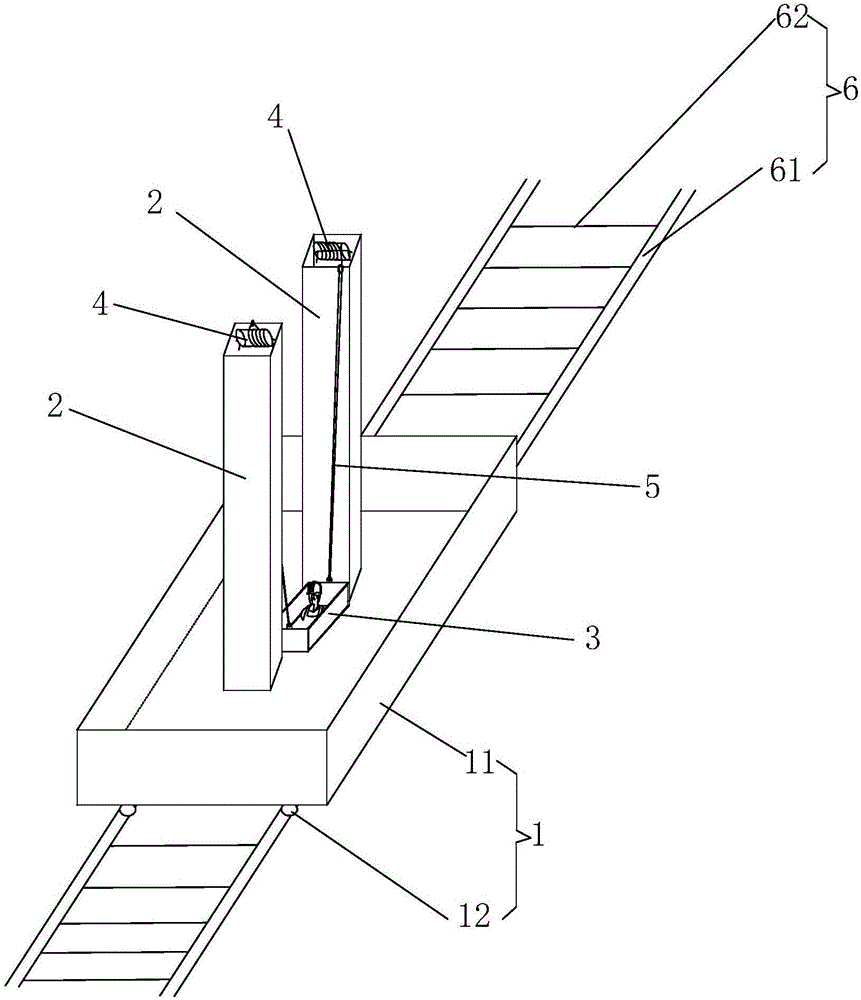

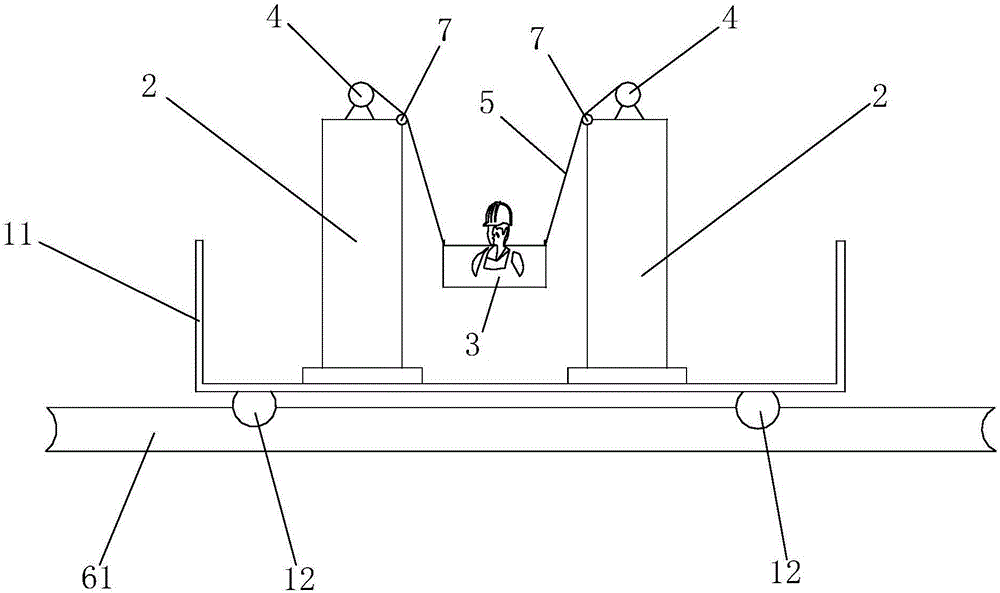

[0027] Such as Figure 1-3 As shown, a kind of mechanical automatic lift platform scaffold tooling of the present embodiment comprises:

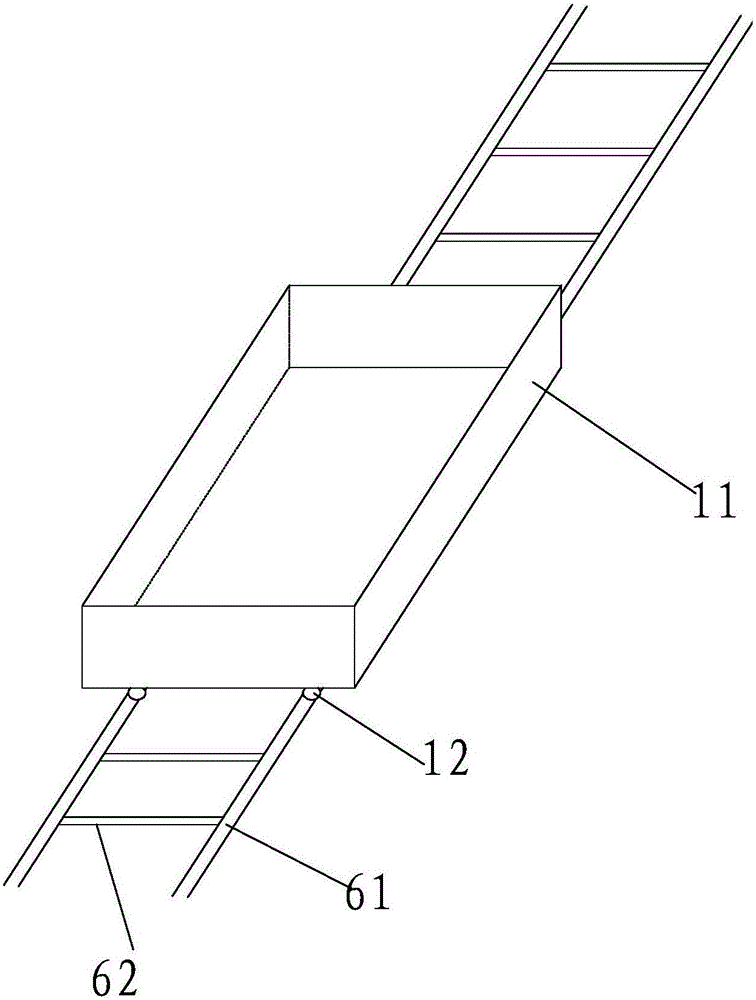

[0028] The traveling mechanism 1 is used to make the scaffold tooling translate along the horizontal direction, and translate along the extension direction of the butt joint 9 of the hull plate 8 during the welding construction process;

[0029] Lift the bracket 2 and fix it vertically on the traveling mechanism 1;

[0030] Hanging basket 3 is used to carry construction personnel to carry out welding construction operations;

[0031] The mechanical lifting device is used for hoisting and driving the hanging basket 3 to rise or fall along the lifting bracket 2 .

[0032] Wherein, the traveling mechanism 1 includes a base 11 , and the bottom of the base 11 is provided with traveling wheels 12 .

[0033] In the present invention, through the cooperation of the walking mechanism 1 and the mechanical hoisting device, operations such as paint s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com